SONALI :The Best Chicken Breed for Eggs and Meat in India

By- Dr.Nirbhay Kumar Singh

Assistant Professor

Dept. of Veterinary Anatomy

Bihar Veterinary College

Patna

The contribution of the poultry sector as an important tool in global efforts to overcome malnutrition and poverty in developing countries is widely recognised.

Poultry often represents a farmer’s first investment in the livestock ladder (followed by goats or sheep and then cattle) as a way of increasing income and emerging from the poverty trap.

The poultry sector in India is dynamic and has potential for rapid poverty reduction through income generation and employment creation.

As commercial poultry farming gains in popularity, employment opportunities are created for rural farmers, retailers, traders, service providers, entrepreneurs, etc.

The current poultry production system in India can be divided into four main categories:

- traditional rural backyard scavenging systems;

- semi-scavenging systems;

- commercial farming systems; and

- contract farming or integrated systems.

Rapid income growth, diversification in food demand patterns, decline in income-induced demand for rice and coarse grains, a dietary shift towards high-value foods, and rapid migration to urban areas are increasing the demand for foods of animal origin; poultry meat and eggs are acceptable protein sources for many population groups.

Production of commercial broiler and layer day-old chicks has declined because of outbreaks of highly pathogenic avian influenza (HPAI), which was first identified in March 2007 and has caused irreparable losses to the poultry industry. India is the 4th largest producer of broiler (meat breed) in the world. Impressed? There’s more – in terms of production of eggs, India ranks 3 in the entire world! The road to efficient poultry farming & management is understanding the anatomy of chickens and accordingly, how chickens that are built differently from each other fare differently in egg production and meat yield comparisons. Let us look at the “SONALI” The top Meat & egg-producing chicken breeds first .

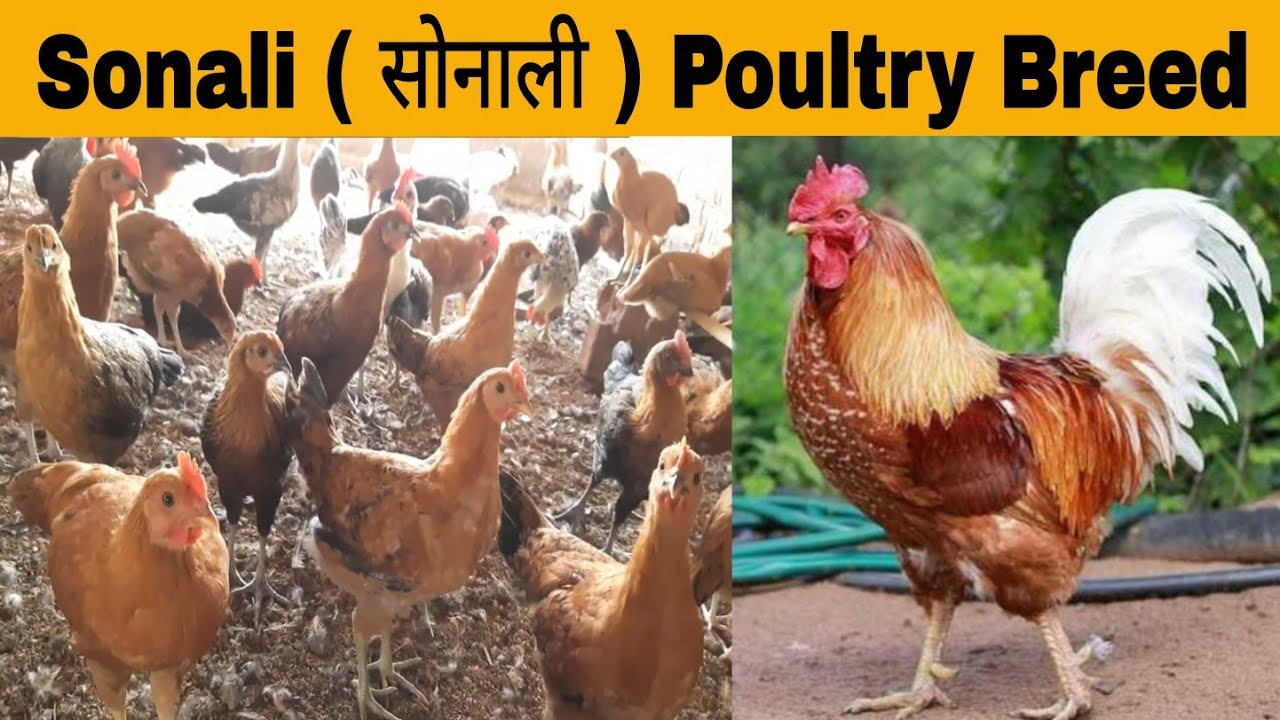

Poultry is one of the best tools for poverty reduction throughout the world. Smallholder backyard chicken production is a subsistence activity, providing egg and meat for family consumption and to some extent, cash income . Local scavenging chicks are dominant in poultry production in India. Fayoumi, an ancient breed from the Egyptian City of Fayoumi for egg production, is well known poultry breed in India. Now a day, it is a well established poultry breed throughout the world and is also popular breed in India, Bangladesh,Pakistan, Sri Lanka and many other countries because of its high profitability with low cost. Farmers can easily rear this breed both in intensive and scavenging systems. The farmers also like Fayoumi because of its bright color. Fayoumi is hardy, very precisions in early maturing and has excellent flying and escaping capacity . On the contrary Sonali breed is a cross breed, which had been produced from the cross of Road Island Red (RIR) cocks and Fayoumi hens. It has specially been advocated in terms of their higher production rate and better adaptability in rural situation . Pure line of RIR cocks and Fayoumi hens has been used for the production of hatchable eggs to be used by broody hens. Body plumage is yellowish red (locally called Sonali, hence the name of the breed). Legs and ear-combs are yellowish. Sonali females produce about 180 eggs per year (Ali et al., 1981). Chick is a young chicken from one day to about 5 to 6 weeks of age either male or female (Banerjee, 2001). But in the scavenging system a young chicken up to 12 weeks old is also called chick (Khan, 2003). This is because the growth rate is low and takes more time for productive and reproductive performances than that of the intensive and semi-scavenging reared chicks

Sonali chicken, the crossbred of Fayoumi female and RIR (Rhode Island Red) male developed in 1986, has been reported to perform better with respect to egg and meat production, rapid growth and low mortality under scavenging, semi scavenging and intensive farming system. It has been taking its place besides the indigenous hens due to its adaptability and acceptability in the climatic conditions of West Bengal. Sonali, with a phenotypic appearance similar to local chicken has higher market demand than exotic breeds. Sonali chicken farming would be an excellent and appropriate way to promote the nutritional and economic security of the people living in rural, tribal and inaccessible areas in a sustainable manner. Sonali chicken production provides higher returns to the farmers

The Sonali is a cross-breed of Rhode Island Red (RIR) cocks and Fayoumi hens and has a similar phenotypic appearance to that of local desi chickens; it was introduced in 1996–2000 in northern parts of Bangladesh. Traders can sale sonali at higher price than broiler. The Rhode Island Red are easy to control, good at foraging, are a utility bird, raised for meat and eggs. They can produce about 200 brown eggs in a year. RIR is used as a father mainly due to the prolific egg laying characteristic which is passed down through the males. Fayoumi hens are good layers of small, off-white eggs and can produce about 200 eggs per year. The breed is fast to mature, with hens laying by four and half months. Weight of Sonali adult male is 2-2.5 kg and adult female is 1.5-2 kg. Egg production of mature sonali is 150-200 per year.

There is numerous importance of sonali chicken. Sonali farm is a source of income and employment as it can be adopted as whole-time business on large scale or part time business on small scale. Even housewife can look after a small flock of birds. Sonali is also a source of protein. Its meat and eggs are the cheapest sources of animal protein for human nutrition. Fertile eggs can also be used in vaccine preparation along with breeder farm. Inedible eggs from hatchery can be used as animal feed and fertilizer. Egg yolk and albumin have also industrial uses. Table eggs can be sold for cash. Capital and labour inputs are low and the costs of production per egg or per kg of sonali are not so much. Meat quality of sonali is similar to desi chickens. Sonali plays an important role in socio-economic condition in village. Sonali farming as a tool of socio-economic transformation of rural people has immense potential in our country where many people live below the poverty line. Economic improvement of rural masses can be substantially achieved with introduction of scientific sonali farming. It provides employment opportunity to young entrepreneur, self-employment to local adult people. It requires less investment and less space to start the enterprise.

Sonali birds are well adapted to the country’s environmental conditions so require less care and attention than other breeds, making them easier for women and children to rear.

Small and marginal farmers started to rear Sonali birds commercially in response to the market demand for coloured birds.

On the other hand, Sonali birds under the semi-scavenging system showed better egg production than local non-descript birds.

The live weight of Sonali meat birds was lower than that of commercial broilers, but Sonali meat raised almost twice the price of commercial broiler meat.

Sonali birds reared under the semi-scavenging system were also found to have better economic returns than birds reared under the intensive system.

Relatively few farmers in the study area practised the semi-scavenging system, but those who did were economically better-off and able to provide their birds with better supervision, more supplementary feeds, better housing and greater care, allowing them to obtain better benefit-cost ratios than farmers practising intensive production.

Sonali intensive meat producing farms achieved higher net returns as well as benefit-cost ratios per bird and per batch than those of commercial broiler farms. With the same flock size, farmers rearing semi-scavenging Sonali could raise almost twice as much income of farmers rearing local non-descript birds under the traditional production system.

Some study found that Sonali birds were used mainly for meat production, where they performed better than other birds in terms of adaptability and benefit-cost ratio. People also prefer Sonali chickens to indigenous birds.

Estimated slaughter weight (kg) 0.86

Age at slaughter 12 week

Age at point of lay (weeks) 24.7

Age of maximum egg production (weeks) 34.0

Weight at end of laying period (kg) 1.6

Before placing the birds into sheds, the whole unit is cleaned and disinfected and kept for two weeks. Phenol is used as a disinfectant and dry rice husk is used as litter. From first day, some farmers increased the space in a farm by following way: day 1-4:- 25 ft long board was rounded and inside of this was used for brooding for 500 chicks. From 4 to 7 day, 42 ft long board was used for this amount.

Brooding

In a poultry starter house, five brooding boxes are placed for the rearing of chickens until four weeks. One hundred chickens are reared in each box until four weeks and heated with 250-watt bulbs in brooding hay boxes. After four weeks it is transferred into the grower house. Chicks of all pens are brooded under the brooder. The chicks are provided with a temperature 340 C at the first week of age, which decreased gradually at the rate of 30 C every week until approximately dropped to 230 C (Table 1).

Temperature maintained in the brooder house

Age Temperature

1 st week 34 ̊ C

2 nd week 31.5 ̊ C

3 rd week 27 ̊ C

4 th week 24.5 ̊ C

5 th week 23 ̊ C

Housing and floor space

The place needed for Sonali depended on how many days it would be reared for. The height of the house is 8-9 ft. The house is constructed east to west direction. The concrete floor is preferable. The floor space required for a Sonali was 0.85-0.95 sq ft.

Feeder and water management

For the first 3 days, the feed was given ad libitum to the birds on newspaper and water was supplied in round plastic drinkers. Two flat types of feeder for 100 chicks were provided. After seven days, one feeder was provided for 40 birds and one waterer for 50 birds (Table 2). The feeders and drinkers were set properly so that birds were able to eat and drink conveniently. Drinkers were thoroughly cleaned and washed every day. Fresh, clear and cold drinking water was made available all the time. Some water-soluble vitamins and antibiotics were supplied to the birds with drinking water.

Number of feeder and waterer requirements for Sonali chicken at different ages

Age Number of feeder Number of waterer

1-7 days 2 flat type of feeder for 100 chicks 1-2 for 100 chicks

8-30 days 1 for 40 birds 1 for 50 birds

after 30 days 1 for 30 birds 1 for 40 bird

Sanitation

About 500 gm salt per 100 liters water is used in the floor & 5 ft surrounding of farm. After drying out 1 kg lime per 1000 sq ft is overlaid in land and after that disinfectant is sprayed in the house. Maximum farmers give one month gap between two flocks.

Litter management

The surface of the floor is covered with a bedding material called litter. It is placed prior to the chick placed in the house. The best way is to remove all previously used litter and wash the house after every flock. The producer mainly used rice husk collected from auto rice mills as litter material. The depth of the litter are 2 inchs in summer and 3 inchs in the winter season. Due to the high possibilityof fungal infestation, they avoided wood savings. Farmer used to stirrer litter materials two to three times a week. Poultry litter is also a good source of compost preparation that is rich in macro and micronutrients for plant growth.

Beak trimming

Beak trimming is done between 7 to 10 days for better growth and feed intake.

Ration

The handmade diet is composed of maize, wheat, soybean toasted, Rice polish, Protein concentrate, salt, limestone and premix . During the starter period (1-35) days, a starter ration containing 20% CP and 2800 kcal ME/kg, is provided to each chicken each day. Three plastic tube feeders and three bell-shaped (round) plastic waters are used to provide feed and water every day in brooding hay boxes. During the growing period (36- 60) days, grower ration containing 18.5% CP, 2700 kcal ME/kg is supplied to each chicken per day

Ration used for different ages of Sonali under intensive farming system Ingredients From 1-60 days

Crushed Maize 50%

Crushed wheat 10%

Rice polish 14%

Soybean 13%

Crushed oyster 04%

Protein conct./bone meal 08%

Common salt 0.5%

Limestone 0.25%

Vit. Mineral pre. 0.25%

Vaccination

Vaccination schedule varies in different areas due to some factors such as weather, the prevalence of a disease in this area, maternal antibody etc. The chickens were vaccinated against the most common chicken diseases of the area namely Newcastle and Bursa (Gumboro), and fowl pox For meat purposes, it was similar to broiler (4 vaccines initially). It is better to give a live vaccine (ND+ Bronchitis) at 42 days of age. At present for meat purposes, the killed vaccine are provided in Sonali flock. In this case, two types of killed vaccine schedule is followed: one is ranikhet killed or ranikhet +gumburo killed at 17 days age and another is vactormune vaccine (preserved in liquid nitrogen) Marek’s+Ranikhet at DOC.

Schedule for vaccination and its route

Age (Days) Vaccine Route

03-05 IB,ND Vaccine Eye Drop

12 IBD Vaccine Eye Drop

17 IB,ND Vaccine Eye Drop

22 IBD Vaccine Eye Drop

25-28 ND Vaccine S/C in Neck

35 F-Pox Vaccine Inj. In Wings

NB-IBD= Infectious Bursal Disease, ND= Newcastle/Ranikhet Disease, F.Pox=Fowl Pox, IB=Infectious Bronchitis

Conclusions

Overall, Sonali birds under the semi-scavenging system were found to have better economic performance than birds reared under intensive management. However, this system requires more extension services like vaccination, technical advice etc. from government and NGOs.

The study found that raising Sonali birds, particularly for meat production under the intensive system, by rural households has good potential in supplying meat for the whole country, increasing incomes and generating employment.

It is interesting to note that the market prices of Sonali birds are far higher than those of commercial broilers. Such price incentives will encourage people to rear more Sonali birds for meat production.

Sonali meat was also found to be less affected by price fluctuations than meat from commercial broilers. Sonali layers are reared mainly as parent stock to produce hatching eggs for hatcheries, which fetch good prices. Their benefit-cost ratio is higher than that of commercial layers that produce table eggs; Sonali birds are less suitable for producing table eggs.

For all production systems, improved biosecurity and proper vaccination are required to prevent and control diseases, especially highly pathogenic avian influenza.

This study found that Sonali meat producers performed better than commercial broilers, Sonali egg producers performed better than commercial layers, and Sonali semi-scavenging birds performed better than local non-descript birds.

Sonali farming has created a value chain in Bangladesh. However challenges persist, particularly the risk of inbreeding and unplanned breeding between Sonali and Sonali and between RIR and Sonali.

Other constraints include the lower productivity of Sonali birds (both intensive and semi-scavenging), which could be addressed by implementing appropriate technology and management practices.

So far, however, stakeholders have introduced few technology packages to increase the population and productivity of Sonali birds in villages in the study districts. Action should therefore be taken to stimulate the development of the Sonali bird industry to achieve its full potential.