Digitalization in Dairy Sector :Engine behind India’s White Revolution -2

Digitalization in milk procurement, processing and marketing

India is the world’s largest producer and consumer of milk. Milk production in the country is expected to continue to report strong growth in the foreseeable future. Milk demand too is expected to rise to 266.5 million tonnes by 2030, according to a study by the National Dairy Development Board (NDDB).

Our per capita milk consumption is well below other major producers, and the cattle yield is also among the lowest. Enhancing yield is one of the key challenges in the Indian dairy sector. In my opinion, it is also a major responsibility so that dairy farmers or milk producers can receive better compensation for their efforts.

This is, however, easier said than done. There are an estimated 96 million dairy farmers in India and the daily production of 440 million liters of milk. Most of these farmers have 3-5 cattle and many of them even fewer. Enhancing milk yields requires improved cattle feed, better cattle health, milk extraction equipment, veterinary facilities, and a host of other factors. Considering the sheer numbers of farmers and bovine cattle, increasing milk yields is a daunting task, to say the least, but the country is on the right track. Efforts are being made to enhance cattle productivity, and the results should start becoming visible in the near future.

Along with improved yields, the major challenge for the Indian dairy farmers is the lack of adequate milk cooling infrastructure. A delay in chilling leads to an estimated three percent or around 5 million tonnes of milk getting spoiled, causing heavy losses to the farmers. Even otherwise, the delay causes a rapid increase in bacterial load, affecting milk’s quality and reducing its potential shelf life.

The currently available solutions are inadequate to achieve the desired quality standards. The absence of a continuous and reliable power supply during chilling is also an issue in many villages. A majority of milk collection centers also do not have cooling infrastructures such as chilling centers, cold chains, or bulk milk coolers.

While these are huge challenges, the other way of looking at them is that they also present a huge opportunity for the dairy sector. Solutions to instantly chill milk at the source are available, and efforts must be made for their higher adoption.

According to projections in the government’s National Action Plan, there is a requirement of 8,80,000 rapid milk chillers in India, and this translates into a $3 billion opportunity.

There is a lot of focus on strengthening the milk cooling infrastructure during the collection and distribution stages by the government and the cooperative or private sector. Still, similar efforts are needed at the farmer’s doorstep to reduce milk wastage if not completely prevent it.

The value added to milk products in India is also significantly lower than other major producers, and this is also a challenge and an opportunity. According to the government’s estimates, there is a potential to add more than 115 million tonnes of additional processing in the value-added dairy products segment in the next five years. This, too, has the potential to attract thousands of crores of rupees in investment and must be tapped.

Talking about digitalization, it is already playing a vital role in the dairy sector and is expected to become a critical aspect in the near future. From farm management, which includes using technology to monitor cattle health and productivity, to milk procurement, comprising automatic milk collection systems and bulk milk collection systems, digitalization is everywhere.

Digitalization also has applications in milk testing for evaluating the quality, screening adulteration, and ushered in greater transparency and traceability throughout the dairy supply chain. The opportunities for digitalization are immense, and even more so because of the greater adoption of emerging technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and Cloud.

The Problem

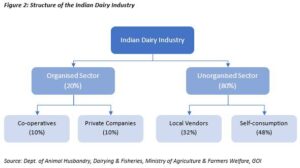

Unlike the West, India’s dairy industry is highly unorganised. About 60% surplus milk is handled by the unorganised sector (milkmen), while the remaining 40% is procured by the organised sector comprising dairy co-operatives and private companies. In developed countries, about 90% surplus milk is handled through the organised sector.

As the dairy industry is unorganised, technology advancements in the sector have been minimal. Lack of technology in this sector has resulted in high wastage and inconsistent quality & quantity of milk for many small farmers. According to research conducted by the Chambers of Commerce and Industry of India (Assocham) and MRSS estimates, about 3% of the milk produced gets wasted annually.

The volume of wastage, coupled with increased demand for dairy products, may hamper India’s plan to produce about 300 million tonnes of milk by 2024. In addition, average milk yield of cows in India is lower than US counterparts—1,248 kgs of milk per cow in a year compared with ~10,000 kgs of milk per year. Indian dairy farmers must increase produce and focus on reducing wastage to meet the target.

The Solution

Adopting technology solutions can help in increasing production efficiency and reducing wastage in the supply chain. Digitalisation will play a crucial role in making the transformation possible.

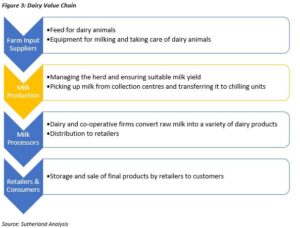

Digitalisation will have a profound impact on the ‘Milk Production’ segment in the value chain. In India, dairy farming is unorganised, so technology penetration is relatively less; however, in the last five years, a few start-ups have mushroomed in this space. These firms aim to increase farmer productivity and reduce wastage.

Cattle management is one of the key areas where digitalisation can have a significant impact. By leveraging the Internet of Things and advanced analytics, farmers can track the feeding pattern of cattle and monitor their health. This is likely to improve cattle productivity and increase milk yield. However, cattle monitoring through AI-based solutions is still at a nascent stage in India and only a few companies are offering this solution.

One such company offering cattle management solution is Prompt Equipments. The company tied up with the Indian Institute of Technology, Mumbai, to offer a wearable belt ‘BovSmart’. The belt utilises AI and the IoT to monitor cattle breeding and send timely alerts to farmers. Another company, Stellapps Technologies (Stellapps), provides a similar mooOnTM solution, which helps in maximising cattle productivity and herd management through a wearable device for cattle and a mobile application, which provides recommendations to optimise herd performance. According to Stellapps, milk yield can be increased by 20% and cattle health expenses can be reduced up to 50% through this solution. About 4.5 lakh cattle are monitored through Stellapps solution.

Apart from cattle management, the other potential areas of dairy digitalisation are supply chain and farmer payments. Supply chain of the Indian dairy industry is quite complex owing to its dependency on various factors such as ambient temperature, availability of cold chains and short shelf life. The fragmented Indian dairy industry further adds to the complexity. Digitalisation solutions such as the IoT and advanced analytics can help by sharing real-time data with different stakeholders, and detecting any deviations in the quality and quantity of milk during phases of transportation in the value chain.

Another potential benefit of digitalising dairy supply chain is better decision-making. Real-time data and advanced analytics help automate activities such as order tracking, inventory management, payments tracking and sales growth and facilitate better understanding of customer purchase patterns. A few start-ups digitalising dairy supply chain in India include Stellapps, Mr. MilkMan and Trinetra Wireless.

Dairy co-operatives and milk unions are also focussing on introducing digital payments to farmers as opposed to using the traditional cash mode. As a large chunk of India’s dairy industry is controlled by small farmers, the process of digital payments has its own set of challenges as most small farmers do not have a bank account. However, dairy co-operatives such as the Gujarat Co-operative Milk Marketing Federation (GCMMF), famously known as ‘Amul’, are opening bank accounts for dairy farmers and instantly transferring payments to them. In 2017, Fino Payments Bank also tied up with Gokul Dairy and Mother Dairy to digitise payments in the milk industry.

Digitising payments should not stop only at depositing money to farmer bank accounts. Considering the Indian dairy industry is majorly controlled by small farmers, it is imperative for corporates to develop solutions to provide farmers access to low-cost financing and insurance.

The global dairy industry is facing conflicting priorities that are mainly influenced by three central factors:

- Increasingly tight social requirements, for example with regard to environment, sustainability, animal welfare and health

- High national and international competition, which is due to milk substitutes and milk imitation products

- A high concentration of demand in food retail

Dairies that consistently address these challenges must understand the topic of digitization. The efficient use of technologies provides new opportunities to reduce costs, to accelerate and automate production processes, and to open up new digital sales channels. In our blog, we have summarized what you, as a decision-maker, should observe.

- Digitization of a dairy: Think big, start small and develop for long term use

Every digitization project in the dairy industry starts with a concept. It is not only important to focus on your own processes in milk processing, you additionally need to take into account current and future needs of customers and consumers. In your initial considerations, determine your target areas for the digital optimization, for example:

- Agriculture / milk production

- Processing

- Packaging & Logistics

- Trade/ New Business

- Consumers

After you have defined the key fields, approaches to enhance the digitization in the respective area will emerge almost automatically. The best way does not start with a highly complex digital strategy, but with small steps. The motto of many dairies, having integrated digitization successfully in their daily routines, is start small and then continue to develop further. One example: In raw milk receiving, the most important data is captured so it can be processed digitally. In the continued process, the use of the value-based ingredients, fat and protein, and their use and application in the products can be digitally tracked in order to enable a software-controlled accounting of the raw material for use later on.

- Full digitization power for milk processing

The biggest digitization potential – and the biggest need – lies in the core processes of the value-adding departments in production. In many dairies, you can still find a great variety of technical solutions, diverse production facilities and automation concepts, some of them still using analog or digital measurement and control technology.

In addition, the data from the ERP system is often not available in production or in the filling department. This leads to error-prone manual entries of the minimum sell-by date.

The good news is, even the smallest digitization step can mean a quantum leap. With a gradual “introduction” or “increasing implementation” of digital control and traceability of production, from the manufacture of semi-finished goods to filling, you can bring out the biggest opportunities for cost reduction or increased efficiency.

Other concrete examples for the use of digital solutions are quality control, accounting of raw material use or projecting maintenance of production machines. By linking measurement technology and evaluation systems, the dividers can be better controlled, and the maintenance procedures can be planned more efficiently.

Picking is an area in which digitization projects pay off very fast. Some years ago, Züger Frischkäse AG from Switzerland achieved a time saving of 50% in picking while minimizing the error rate through a combination of high-bay storage and mobile data capture.

- Use of the ERP system for interlinking the dairy

ERP systems in production are the obvious choice in order to achieve the overall goal of interlinking all departments, processes and stakeholders. Today eight out of ten dairies data is not merged at all, or merged only partly, with the data from the enterprise resource planning system. This offers a great potential to create better transparency in production.

ERP systems are capable of exchanging data with the process control systems in production. Consequently, they become the central nervous system in the dairies, as they are able to communicate with the various automation systems.

Merging the commercial and technical systems makes it possible to link, evaluate and utilize the data from sales, purchase, production, QM, maintenance and other data from plant control systems. At the end of the day, this provides the necessary transparency for the corporate management. Rene Guhl, managing partner of Naabtaler Milchwerke: “We don’t have the time to ask where data comes from and how it was prepared, which is why we have jointly developed our ERP system to provide a decision-making basis whenever we need it. We no longer have piles of paper documents or Excel spreadsheets, from which we had to laboriously extract the information we needed. All management decisions, whether operational or strategic, are based on live actual data.”

Behind this is a strategy of one hundred percent integration, which covers more than mere production. Naabtaler uses the ERP system from start to finish: from asset accounting to time management, and from laboratory integration to maintenance.”

- Digitization is the basis for the traceability of dairy products

Imagine a bad batch of your top-selling yogurt was placed on the market – and your employees have to first look through folders to find the right information. Quite a problem, isn’t it? How much easier would it be if your ERP system informed you at the push of a button from which raw milk, which other raw materials, and when the yogurt was produced?

Each digitization step improves the traceability of dairy products – and this not only becomes an added sales-promoting value, but a prerequisite to doing business with purchasers in food retail, in the export business, and in the processing industry. Therefore, digital information must be made available by consistent input, evaluation, and linking of data from the various business areas.

Again, the ERP system plays the pivotal role in merging this data: It combines the data from the process control system with the data from purchasing and from the laboratory, integrating the information of measuring devices and scales. In the end, this multidirectional information flow supplies the precise and quick evaluations that are required in case of a recall.

Today in daily business only few dairies are able to portray traceability in audits at the push of a button. In most cases, this work is still very timely and resource intensive, which means a lot of stress for quality management. Companies relying on digital support can concentrate on controlling and monitoring the processes. This also creates additional flexibility for the optimization of the entire processes.

- Digitization is people business: Clarify important questions in advance

Robotics and AI will be here – but not very soon. Until then, the digitization of dairies primarily will remain a project that will be implemented together by people from various disciplines.

This gives you the opportunity to discuss and clearly define important matters in advance. For example with regard to the technical possibilities that are available for your project. Only with the joint commitment of all participants, can the tasks of the project ultimately be solved. This sounds obvious, but in fact this point is frequently raised in discussions. One example: If the existing technical systems do not allow automatic data processing, you have to find another solution as a “bridge”. A laboratory device that cannot send data to the ERP system is no showstopper at all. In such a case, you can attach the label of the respective production batch to the reports, scan them and allocate the data / information to the respective production in the QM system.

How is technology changing the dairy industry?

At Farm Level:

The dairy sector’s primary constraint is the low productivity across dominant species of dairy animals- cows and buffaloes. The population of high-yielding cross-bred animals has seen slow growth in India, contributing only 28% of the total milk production, with the rest being contributed by the indigenous breeds. Apart from productivity challenges, animal health monitoring, lack of quality fodder and feed, and limited market access, have been critical bottlenecks in the dairy sector. Precision dairy farming has been introduced to maximize animal performance and early detection of diseases in cows. In 2018, the Karnataka government implanted GPS-enabled digital chips to the ears of 56 lakh animals across the state to track their health and early diagnosis of any medical condition. Cattle monitoring via AI-based solutions is still in its infancy in India, with only a few companies providing this service. Stellapps Technologies is digitalizing and enabling supply chain traceability for dairy companies by developing a wearable technology that helps in efficient herd management. Companies such as Allflex and GEA are offering RFID tags for cattle management in India. Ag-tech start-ups like Brainwired and VetWare have developed herd management applications for better cattle record keeping.

Collection and Procurement:

Over the years, reports and surveys by FSSAI have shown high levels of adulteration and contamination in milk. More than 5% of the milk tested by FSSAI in 2019 was reported to be contaminated with Aflatoxin M1 residues and deemed unfit for human consumption. Cases of intentional adulteration of milk to increase the volume by using water, increasing thickness through adulterants like glucose, starch, and paint, have also been reported widely in the country. Rapid milk quality testing kits have been recently approved by FSSAI, which can help curb these instances at the procurement level and monitor and maintain the quality of milk for processing and further value addition. The FSSAI approved kits for detecting aflatoxins, antibiotics, and microbial contaminants in dairy are supplied by players such as Unisensor, 3M India Ltd, Jupiter GlassWorks, Delmos Research Ltd., etc. Apart from testing at the collection centres, at-home testing kits have also been developed by companies like Biosyl Technologies and VeriPure for customer reassurance.

With the increase in the complexity of the dairy supply chain system, consumers know very little about the products produced or processed by producers or processors. Such information asymmetry present in the dairy industry has serious concern over human health, environmental sustainability, and welfare issues. There is a need to improve the communication between the supply chain players to enhance coordination and maintain traceability. Blockchain adoption in dairy can provide complete transparency in the end-to-end order and delivery process, thereby increasing adherence to regulatory norms and decreasing the instances of adulteration. This system can be used in tracing food information, including farm operations conducted and support in building a trust level among the various stakeholders. Reliable tracking of every batch in the milk value chain can help establish traceability, identify the defective products and discard the batches that have been impacted.

Processing and Transportation:

Although the dairy industry is not an energy-intensive sector, higher energy needs are requisite in the proper storage and transportation of milk. Remote regions with many dairy farms do not have adequate electricity to power cold chain facilities, leading to loss.

Dairy farms in remote locations with poor grid connectivity are at a severe disadvantage and face loss in quality and economic terms. According to ASSOCHAM estimates, about 3% of the milk produced gets wasted annually. A diesel generator for power backup is the current option for village-level chilling, which is expensive, less eco-friendly, and needs regular maintenance. Alternatives such as thermal energy-based storage and chilling systems by players such as Promethean Power Systems and Ecogen Energy can address the needs of dairy farms in off-grid locations. With thermal energy-based cold storage being a more cost-effective replacement for diesel-generator backup, collection centres and dairy processors are assured of better quality and volumes of milk and lower operational costs.

The dairy industry has a large carbon footprint during milk processing from the farm to the retail supply chain. Water consumption during milk production and processing is also high, which can be controlled through sustainable solutions. Wastewater treatment in the dairy industry in India is done in three phases through filtration systems, effluent treatment systems, and aerobic treatment. These methods require more efficiency with the increased production capacities. The introduction of cloud-based technologies can help the dairy industry reach maximum efficiency and reduce water consumption through smart monitoring and real-time water usage tracking. Fluxgen Engineering Technologies, a Bangalore-based start-up, uses IoT and AI to help manage and regulate water usage in food processing and manufacturing plants, can use efforts to increase efficiency in such processes through digitization. Their AquaGen system helps in real-time productivity and water consumption monitoring, which has reduced water usage by 15%, translating to monetary savings for a dairy farm in Puducherry.

Export Market:

There is a broad scope to improve and increase the processing capacity of industries and direct a more significant share of milk and milk products through the formal channel. With the shift towards convenience products, there is a need for advancements in the processing and packaging of milk products. Appropriate R&D interventions and newer developments in the dairy processing area, focusing on novel aspects of emerging technologies, can help alleviate the quality of these products in the domestic and international markets. India’s low share of dairy exports globally (0.36%) can be increased with increasing processing capacity of products that hold potential in the global market, such as cheese, skim milk powder, whole milk powder, and butter, and improving quality capable of meeting international requirements.

Retail and Distribution:

Keeping track of trucks and tanker routes and capabilities for viewing, monitoring, and payment based on route or distance has been complex in a largely unorganized market in India. The Kerala state government is implementing a project to leverage blockchain technology to streamline the state’s milk, fish, and vegetable purchase and distribution. The project aims to ensure speedy delivery of high-quality milk by continuously monitoring production, procurement, and distribution through an electronic ledger.

A fault in the proper transfer of dairy items by such companies leads to spoilage of products due to the perishable nature of these food commodities. Integration of the internet of things with the Blockchain platform helps gather the information needed during the transfer of goods from one place to another to be easily traced.

RFID tags and mobile applications are being used to monitor the movement of trucks and refrigerated tanks to make sure they adhere to fixed parameters like the temperature in which the products are to be kept to maintain the quality of the products. Indian dairy-tech start-up Mr. Milkman is a last-mile dairy supply chain SaaS platform that enables dairy food product companies to efficiently manage multiple aspects of dairy distribution, supply chain, customer subscriptions, and delivery requests.

With dairy-tech start-ups entering the space and bridging the gaps in cattle management and the supply chain, the scenario is changing. There is a need for investment in technology to keep up with the changing consumer needs for transparency, traceability, and quality assurance. The future of the Indian dairy sector appears bright, as digitalization is expected to usher in a new era of growth.

Technology has been the main driving force in bridging the intelligence and efficiency gap although it may not seem apparent but new technologies involving sensors and big data analytics are making farms approach light speed efficiency in how they operate.

There’s currently a huge influx of big data through sensor in the agricultural economy.

Sensors are what recognize cows through their spot patterns, internal and external behavior, nose print, width between the eyes, placement of the ear tag, or the length of their head. Information gotten from hundreds of these sensors can then be processed for autonomous machine control that matches each individual animal. Examples includes a tractor connected to an online mapping system to harvest overgrown hay, moisture precision devices placed amidst crops that can detect sunlight levels, pest pressure in the environment, water and nutrient levels. Ill cows can be easily spotted while grazing

Here are some modern gadgets and devices that will aid in boosting milk production and herd management:

Robotic cow milking equipment

“This multi-million dollar technology is by far the most well-known application of robots in the dairy industry,” said Chen Yuanrong, the founder and chairman of Blue River Nutrition. “It not only milks the cows, but it also washes, massages and feed cows.”

Whereas prior to robots, cows were only milked twice a day due to time and labour constraint; with robots, companies like Delaval robotic milking system and miRobot, provide milking systems that are able to milk multiple cows simultaneously while maintaining a clean and sanitized environment to keep the cows in healthy comfortable shape. Cows seem to enjoy getting milked three or more times as they often go back on their own free will.

Use of drones

Through aerial monitoring of land and cows grazing, farmers can respond immediately to emergencies and possibly save the life of crop or an animal. With development in battery life and autonomous flying ability, drones will be able to map, inspect/survey and photograph pasture areas where growth has been detected suitable for cow grazing.

Rotating swinging cow brush

Used for almost a decade. This is a simple rotating brush similar to one used in a carwash but made specifically to match the contours of a cow’s body.

It rotates at a comfortable speed that cows love and often queue to be next in line to use this massager. In an effort to boost cow’s comfort, research shows the rotating cow brush aid blood circulation which in turn improves milk production and child birth

Collar technology

An ID collar that sends information to the farmer through a transponder to keep track of cow’s health, milk production levels, milking frequency and how much activity the cow is getting vs. how much the cow is eating. This wearable technology is vital in individual cow management as it allows farmers to detect cow’s welfare and quite possibly respond before milk production or the herd is affected. SCR Diary is a market leader in the area of animal wearable technology which can be worn on ears, neck, legs or tail.

3D Printing

There are a multitude of applications of 3D printing in the dairy industry. A primary application is the replacement of machine parts in rural farmers will not only save valuable time but also money.

As 3D printers become more and more accessible, research is ongoing to re-engineer dairy products cutting out the use of cows itself. This means milk consumption which has been dwindling in countries like US and UK due to deficiencies such as lactose intolerance can be reversed and there will no longer be any reason to avoid it.

Conclusion

India’s dairy sector is unorganised and so, its future rests on supporting small dairy farmers. Advent of the latest technology and digitalisation have been slow in the sector, resulting in lower productivity and wastage. However, the scenario is changing with start-ups entering the space and bridging gaps in cattle management and supply chain. The future looks bright for the Indian dairy sector, as digitalisation is expected to usher in a new phase of growth.

Reference-on Request

https://www.pashudhanpraharee.com/roadmap-of-evolving-livestock-sector-in-india-to-a-farmer/