CONCEPT OF ECONOMIC FEED FORMULATION FOR COMMERCIAL LAYERS

Post no-1078 Dt-03 /02/2019 Compiled & Edited by-DR RAJESH KUMAR SINGH ,JAMSHEDPUR, JHARKHAND,INDIA 9431309542,rajeshsinghvet@gmail.com

Feed formulation is the process of quantifying the amounts of feed ingredients that need to be combined to form a single uniform mixture (diet) for poultry that supplies all of their nutrient requirements. Since feed accounts for 65-75% of total live production costs for most types of poultry throughout the world, a simple mistake in diet formulation can be extremely expensive for a poultry producer.

Feed formulation requires thorough understanding of the:

(a) nutrient requirements of the class of poultry (e.g., egg layers, meat chickens or breeders);

(b) feed ingredients in terms of nutrient composition and constraints in terms of nutrition and processing, and

(c) cost and availability of the ingredients.

Most large-scale poultry farmers have their own nutritionists and feed mills, whereas small operations usually depend on consultant nutritionists and commercial feed mills for their feeds. It is therefore essential that formulations are accurate because once feeds are formulated and manufactured, it is often too late to remedy any mistakes or inaccuracies without incurring significant expenses.

Principles of feeding

Nutrition and feeding in early part of life do not have influence on subsequent laying performance. Fast growth is also not the criteria in rearing replacement pullet. The major objective is to raise them at good health to attain sexual maturity at a given weight depending upon genetic make up of the birds with minimum nutritional input. Modern layers, however, rich to the sexual maturity i.e. the point of lay at little earlier age than ever before, as a result the birds have been able to produce 310-325 eggs per year. Besides nutrition the other factors that influence the age of sexual maturity includes season of hatch, duration of light days, light stimulation, overall management and stress and diseases. Light plays important role on age at sexual maturity. Decreasing duration of day light delays sexual maturity. A low protein and/or low energy diet, or quantitative restriction of a balanced feed also delays sexual maturity. A larger egg size is obtained from delayed sexually matured birds. Reaching to sexual maturity at an earlier age is always associated with smaller size of eggs.

Growth phases of egg type pullets —————

The laying may be typed as laying hens for production of table eggs (for consumption of human being) and laying hens for production of settable eggs (for hatching). The former type is called layers and the second type is called as breeders. The body weight and nutrient requirements are almost similar for both the groups except certain micronutrients, which are given in excess in breeders diet. The replacement pullets are generally reared in three phases starter (0-8 weeks of age), grower (8-20weeks of age) and layer (20 weeks or above). In certain countries a five phases feeding system has been recommended i. e. starter (0-6weeks of age), grower-I (6-12weeks of age), growerII (12-18weeks of age), grower-Ill (18-to 1st egg) and layer (20weeks or above).

Production phases of layers —————

The layers are fed in phases, generally three (phase I 18-35wk of age, phase II (35wk – 50wk) and phase III (50wk and above) but laying period can be divided into more phases depending upon the age for economic feeding of layer. The phase I is characterized by increase in body weight to achieve mature body weight, increase in egg size and increase in egg number. The phase II is characterized by increase in egg size and maintaining peak egg production and body weight achieved in phase 1. In phase III egg size is increased but egg production and body weight are decreased. Thus, the requirements of protein and energy alter.

Economic Feed Formulation ————–

Economic feed formulation requires attention in precise nutrient supply (nutrient supply matching the requirements), inclusion of locally available low-cost feedstuffs in feed formulation and use of effective supplements and feed additives for improved utilization of feed.

Nutrient requirements ————–

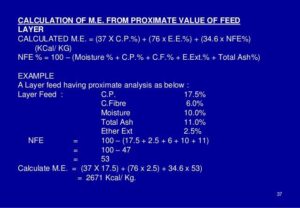

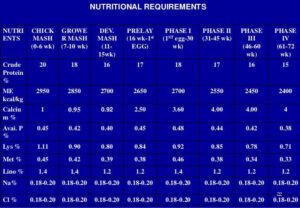

The requirements of energy and protein are much lower than the broilers. The raising system also one of the determinant of dietary energy concentration. The layers reared in cages require less energy than those on litter, as the movement is restricted in cages, thus saving energy. Similarly the growth is more in starting phase and then decreased in growing phase, and thus requirements of energy and proteins are decreased with age up to growing phase. Thereafter, again increased slightly in laying phase. The energy concentration ranges from 2650 to 2850 kcaljkg during starting, 2600-2900kcal per kg during growing and 2500 to 2800 kcaljkg diet during laying phases. Similarly the requirements of protein for the corresponding phases are 18-20%,15 to 16% and 15 to 18%. The requirements of nutrients specified by NRC, BISand Degussa are given in Table 1 to 5. NRC (1994)recommendations provide much energy (2800-2900kcal ME/kg). It becomes difficult to provide such amount of energy under Indian condition, thus the dietary energy level is kept in between 2500to 2700 kcal ME/kg during growth period. Moreover, being tropical country the maintenance requirement is slightly lower. Lower energy level in diet is associated with more feed consumption per unit gain or egg production (higher feed conversion ratio). In laying hens the dietary energy concentration ranges from 2550 to 2700 kcal ME/kg. On an average one laying hen producing 90% egg requires 16-18gram of protein and 285 to 290 kcal ME per day. The protein and amino acid profile in diet is important for optimum growth, feed conversion, egg size and egg production. Meeting calcium requirement is important during overall growth (0.9 to 0.7%) and laying phases, but most crucial during laying phase. The requirement of calcium for commercial layers is increased much (4.0 to 4.5g/bird/ day) in diet. Just prior to initiation of egg production, huge amount of calcium is stored in bones, which is sufficient for 6 to 30 eggs. Therefore, calcium concentration is increased to about 2% of diet a week before onset of egg production. Once egg lying is started the birds adjust calcium requirements from dietary intake and also drawing from body reserve. The specific gravity of eggs hell is increased with increased calcium concentration in diets. The White Leghorn hens producing 90% egg require about 4.5 g of calcium daily. The half of the calcium in diet should be supplied through coarsely ground powder and remaining half as grit so that the needy hens may select and consume calcium as per need and palatability of feed is maintained. Therefore, in addition of dietary calcium (3 to 3.5%),there should be continuous excess to shell grit to the birds. Shell grits improves digestion and utilization of other nutrients also by helping in grinding of feed materials in gizzard. Addition of grit of appropriate sizes in mash at an interval of every two to four weeks may be beneficial. The retention of calcium during first 40 weeks is about 55% and decreased thereafter with age. Thus, requirement of calcium is increased with age. Heavy birds consume more feed, thus dietary concentration of calcium should be lesser. Any factor that affects feed intake like ME content of diet, environmental temperature, etc. will affect calcium concentration in diets. The available P requirements

are 0.4% in starting, 0.35%during growing and 0.28 to 0.35%during aying phase (300 to 350mg/ day/layer).

The egg laying hen needs nutrients for: 1. body maintenance, 2. early in the lay cycle growth, and 3. egg production. An overabundance of nutrients will lead to in- creased bird growth along with increased egg size. The amount of nutrients the layer receives is depen- dent on: 1. the level of nutrients in the feed (% protein, % specific amino acids, Metabolizable Energy (kcal/ kg), % calcium, % oil/fat, etc.), and 2. the amount of feed intake A 100 g/bird/day feed consumption of a ration with 19% protein, .45% methionine, 2850 ME kcal/kg and 4 % calcium means the birds are getting daily the 19 g protein, .45g methionine, 285 kcal and 4 g calcium needed for production of a large size egg.

Alternative feed resources ————–

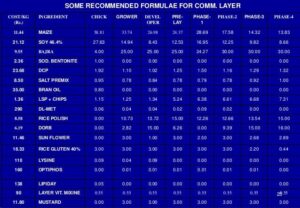

Maize and soybean meal are conventional feedstuffs used in poultry diet. However, the various alternative feed resources available in India, which can be used in place of maize and soybean meal, depending upon the availability in local market, their quality and cost. 1. Cereals: The alternative cereals of maize, which can be used partly to replace maize depending upon availability, are broken/undersized wheat, broken rice, paddy, bajra, jowar (white, brown, yellow), oat, barley, ragi, fox tail millet, kodo, etc. 2. Cereal by-product: The different cereal by-products, which can be used, are rice kani (broken rice), rice polish, rice bran, rice bran (de-oiled), wheat bran (use may be restricted in poultry diet), hominy feed, maize gruten meal, maize germ meal, maize germ cake, maize grit, rice gluten, dried distillery grains with soluble (DDGS),etc. 3. Oilseed by-products and meals: Soybean meal is the conventional proteinic supplement in poultry diet. However, different proteinic by-products that can be used replacing soybean meal are groundnut oil meal, mustard/rapeseed meal, sesame oil meal, sunflower oil meal, safflower oil meal, neem seed meal, karanja cake, kusum cake, linseed oil cake, cotton seed cake, niger cake, coconut meal, mahua cake, palm kernal cake, guar meal (raw), high protein roasted guar korma, peas, different pulse losses, etc. 4. Animal protein sources: Different protein sources of animal origin can be component of poultry feed. The meals/products that can be used to replace soybean meal are fish meal, meat meal, meat cum bone meal, tarula yeast, blood meal, poultry by-product meal, hydrolyzed feather meal, silk worm pupae meal, dry skim meal, shrimp meal, etc. 5. Leaf meals: Different leaf meals can also be used depending upon the type of diet and need. The various leaf meals that are added in poultry diet are alfalfa meal, berseem meal, subabulleaf meal, groundnut haulm meal, etc. 6. Miscellaneous: The other items, which can be used in poultry diet, are molasses, cassava meal, animal fat (tallow, lard), fish oil, vegetable oil, poultry droppings, coffee waste, etc

The inclusion rate of different alternate feed resources:—————

Ingredient Inclusion

rate (% of diet)

Cereals

Maize ———72 ——–Can be added at any level to meet requirements of energy. –

Broken wheat ——–50 ———-New wheat is to be restricted, coarsely ground

Broken rice——– 40——– Must be free from moulds

Paddy ———-30 ————–Must be crushed

Bajra (Pearl millet)——— 50 ———Its use should be restricted in summer

Jowar (white) —50——— Should be coarsely ground, kharif jowar quality may not always be good

jowar (brown)— 30 ———–Should be coarsely ground

jowar, (red) —–15 ———-Should be coarsely ground

Ragi (finger millet)—- 15——- It is generally costlier and used in baby food being rich source of calcium.

Foxtail millet—— 30 ——-May not always be available at cheaper price.

Barley ———-20 ——–Use is limited, may be used in low fibre high energy diet

Phase feeding layer programs are based on these types of principles.———–

1. Protein: Need 18-19 grams of protein/bird/ day for large egg production. Decreasing protein level by too much will decrease egg numbers as well. Supplementing with artificial amino acids allows room to lower protein and improve amino acid balance closer to the laying hens’ nutritional requirements. 2. Amino Acids: Lowering the methionine level and Total Sulfur Amino Acids (TSAA) level in the diet will aid in decreasing egg size. 3. Energy: Birds eat for energy so ensure feed/ energy intake meets the need of 280-310 kcal/ bird/day for large egg production. Maintaining caloric intake at levels needed for egg production and body maintenance with little excess will ensure the bird doesn’t over consume energy and put on excessive weight. Birds on the floor require 5-10% more energy depending on pen temperature and flock activity level. Heat stress will decrease feed and energy intake along with egg size and egg numbers. 4. Oils/Fats: Decreasing unsaturated fatty acids (like linoleic acid) and total oil/fat levels in the diet will affect yolk size and therefore egg size. Excess oils/fats like linoleic acid are deposited in the yolk, increasing yolk size and egg weight. Most vegetable oils (soybean, canola) are higher in unsaturated fatty acids than fats from animal sources. Adjusting ration levels is difficult for many egg producers that produce eggs from diets with no animal bi-products. A saturated fatty acid like palmitic acid does not have the same effect on egg parameters. Digestion of oils/fats produces less body heat so a higher percent of energy from oils/ fats should be considered in warmer weather. 5. Decrease daily feed intake: Adjust the ration, the pen environment and management practices. 6. Increase egg production: Feed mainly used for egg production and body maintenance. Birds that come into production early tend to lay more eggs but of a smaller size. 7. Minerals: Four (4) grams of calcium/bird/day are needed for large egg production. As the egg size increases the amount of egg shell laid down on the egg does not necessarily increase. Like a balloon, as the egg size gets bigger the egg shell gets thinner. With a Phase Feeding Program ration calcium levels should increase as the layer ages while phosphorus levels are decreased.

Feed formulations should be related to feed consumption levels and stage of the production cycle. When a pullet flock starts egg production the feed consumption/bird/day is around 75-80 g/bird. The first few eggs are usually smaller in size so nutrient requirements aren’t as high. The feed consumption target is to get the daily feed consumption to a level that supports large egg production (56-63 g/ egg weight) usually at about 100-105 g/bird/day and before 30 weeks of age. The challenge is to get the hens eating at the proper level and achieving the large egg size, then trying to maintain these levels of feed consumption and egg size throughout the lay cycle. Checking bird body weight every six weeks allows the egg producers to know if the ration is well balanced and meeting the body maintenance and egg production requirements. Too much increase in body size may be pointing to an imbalanced ration with excess nutrients being consumed. The phase feeding program for layers should be based on egg size or egg mass not percent production. Minerals in the layer diet like calcium and phosphorus must be adjusted as the laying hen ages, to compensate for the decreases in calcium utilization in aging birds especially after 40 weeks of age. As the egg size reaches or significantly exceeds the target weight switch to rations with lower oils, methionine/TSAA and phosphorus, and increased calcium. When aging layers continue to produce eggs that are at the target egg weight and production level, the ration only needs adjustments in the calcium and phosphorus levels; so egg shell quality can be maintained. With proper monitoring of flock performance and egg product condition, the egg producer has the tools to efficiently produce the egg product the consumer wants with optimum returns. It’s just common sense that less feed and more eggs at a lower cost should stimulate egg producers to improve their husbandry and nutritional skills to benefit from the ever improving layer hen available today.

Recommended rations (per quintal of feed) for various age groups of layers

Composition Unit Chick mash

(0-8 weeks of age) Grower mash

(8-20 weeks of age) Layer mash

Phase I Phase II

(20-45 weeks) (45-80 weeks)

Yellow Maize kg. 29.0 26.0 35.0 40.0

Rice Polish kg. 33.7 43.8 32.1 31.1

Wheat Bran kg. – 2.0 – –

Groundnut cake (expeller pressed) kg. 22.0 13.0 17.0 12.5

Fish Meal kg. 10.0 7.0 6.0 6.0

Lucerne Meal kg. 3.0 3.0 3.0 3.0

DL-Methionine gm. 4.0 – – 15

Molasses kg. – 3.0 – –

Mineral Mixture kg. 2.0 2.0 3.0 3.0

Vitamin A+B2+D3 supplement gm. 20 20 30 30

Vitamin B12 supplement gm. 20 20 20 20

Vitamin K mg. 100 100 100 100

Vitamin E mg. 200 200 200 200

Potassium lodide mg. 20 20 20 20

Manganese Sulphate m. 5 3 3 3

Zinc Carbonate gm. 8 5 3 3

Shell Grit kg. – – 3.8 4.3

Antibiotic feed Supplement gm. 50 50 50 50

Zinc Bacitracin gm 100 100 – –

Coccidiostat gm 50 32 – –

There is need to improve the scientific knowledge for utilizing low cost locally available agro-industrial by-products in poultry feed in order to reduce the feed cost. As feed constitutes 60-70 % of the total cost of production, any attempt to reduce the feed cost may lead to a significant reduction in the total cost of production.

Preparing of layers chick mash (1-4 weeks)

chicks require feed with Digestible Crude Protein (DCP) of between 18 to 20 per cent. Amino acids are important nutrients in all feeds in order to make a complete feed for all animals. For hybrid chickens, the addition of amino acids is very important to maintain a balanced diet for fast growth

(50 kg bag of chick mash)

• 22.5kg of whole maize

• 6.5kg of wheat bran,

• 5.0 kg of wheat pollard,

• 12 kg of sunflower (or 12 kg of linseed),

• 1.1 kg of fishmeal

• 1.25 kg of lime

• 30g of salt

• 20g of premix

Amino acids to be added

• 70g of tryptophan

• 3.0g of lysine

• 10g of methionine

• 70 g of threonine

• 50g of enzymes

• 60g of coccidiostat

• 50g of toxin binder

To make a 50 kg bag growers feed (1 to 8 weeks), it is very necessary that pullets or young layers should be provided with a feed having a protein content of between 16 and 18 per cent. Such feed makes the pullet to grow fast and prepare for egg laying.

Note: Layers’ feed should never be fed to chickens younger than 18 weeks as it contains calcium that can damage their kidneys (they can develop kidney stones), which interfere with egg production and also shorten their lifespan. Grit (sand) should be provided to growers that are not on free range to aid in digestion.

70 kg bag layer mash (18 weeks and above)

• 24.3kg of whole maize

• 8.6kg of Soya

• 5.7kg of fishmeal

• 7.1kg of maize bran, rice germ or wheat bran

• 4.3 kg of lime

• 180g premix

Amino acids to be added

• 70g lysine

• 35g methionine

• 70kg threonine

• 35g tryptophan

• 50g toxin binder

Note: Layer feed should contain a Digestible Crude Protein (DCP) content of between 16-18 per cent. Calcium is important for the formation of eggshells (Laying hens that do not get enough calcium will use the calcium stored in their own bone tissue to produce eggshells). Layer feed should be introduced at 18 weeks.

Important tips

• When making home made feed rations, it is important to do experimental trials. Isolate a number of chickens, feed them and observing their performance. If the feed rations are right, the broilers will grow fast and the layers will increase egg production (at least 1 egg after every 27 hours).

• Farmers should be very careful with the quality of feed ingredients or raw materials. Poultry, especially chickens are very sensitive to feeds that contain mycotoxins which are present in most of the raw materials. Never use rotten maizeto make chicken feed.

• Buy quality fishmeal from reputable companies. If omena(silver cyprinid) is used the farmers must be sure of its quality; most of the omena in the open-air markets may be contaminated.

• It is very important to mix all the micronutrients (amino acids) first before mixing with the rest of the feed.

• For mixing, farmers are advised to use a drum mixer (many welding artisans can make one). Never use a shovel to mix feed because the ingredients will be unevenly distributed.

• Never use rotten raw materials like maize to make feed. Rotten materials might contain mycotoxins which are detrimental to poultry health.

• Small scale families can contribute resources to the making of feed to ensure high-quality feed materials are used and also reduce costs.

Note: To improve on the feed quality, farmers making their own feeds should always have it tested to ensure the feed is well balanced.You can take your feed samples to agro-chemical industries for testing to ensure the feeds are balanced nutritionally.

Why the feed cost increasing now-a-days?

Feed is the major input and feed cost is the major constraint but a major mean for manipulating production cost and making enterprise profitable. A sizable quantity of cereals and edible oil seed meals are used in poultry ration, and thus compete with the human being directly. Hence availability of feed resources could be one of the major constraints in poultry production in future as the opportunity for the area expansion for cultivation is almost exhausted. Therefore more careful approaches to sustain the poultry industry in the competitive market should be the reduction of cost of production, production of safe and quality products to meet the consumer’s demand and also to ensure the birds welfare to satisfy consumers. Again production of feed stuffs fluctuates greatly due to frequent monsoon failure, low productivity, insects, weeds, environmental concerns, cost efficiency, sustainability, declining area under cultivation etc. Further the farmers are also encouraged for diversion towards production of cash and commodity crops. These factors contributes the production of poultry feed ingredients in decreasing trend in recent years and increasing demand so the cost of feed ingredients goes high .In the recent past, the feed industry experiences very tough on back of considerable increase in cost of feed ingredients (Maize and Soya meal) touching record highs and realizations suffering on back of oversupply in industry.

By considering the growth rate of poultry sector in our country and requirement of major poultry feed ingredients like maize and soya bean meal, more emphasis should be taken to identify more new feed resources with their quality and availability. Assessing data base on feeding values including nutritive value, availability of nutrients and safe level of inclusion of alternate and newer feed resources both at regional level and national level should be done systematically and should be made available to all the nutritionists and farming community. Identification of incriminating factors and their detoxification process should be done at all level of research for the effective utilization of the newer feed resources.

However, the key concern is the existing lack of storage, cold chain, transport and processing facilities. High feed costs also result in an increased cost of production which translates to higher prices. Other challenges include a lack of quality standards which result in high vulnerability to disease outbreaks.

Reference-On Request