CONCEPT OF TOTAL MIXED RATIONS (TMR) -A NEW TRENDS IN LIVESTOCK FEEDING

Compiled & Edited by-DR RAJESH KUMAR SINGH, JAMSHEDPUR, JHARKHAND,INDIA

9431309542,rajeshsinghvet@gmail.com

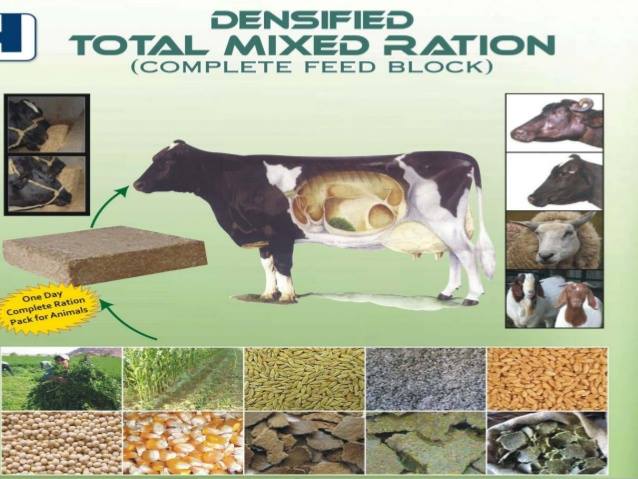

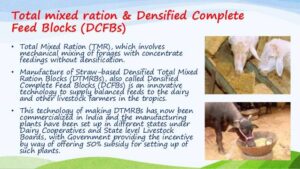

With a Total Mixed Ration (TMR), every mouthful that a cow eats should be a balanced ration. The benefits of a TMR include less feed selection by the cow, synchronization of carbohydrate and protein availability in the rumen, and lower rumen acidity. A TMR may save labor and facilitate feeding commodity feeds. The main disadvantage of a TMR is the inability to feed cows as individuals. Larger farms with more groups of cows are able to minimize this problem. Forages and other wet ingredients should be fed on a dry matter basis. Increase or decrease the TMR ingredients in constant proportion. Beware of overmixing and sorting problems that can result in acidosis.

A ration is not a TMR if: hay is fed separately, a computer feeder is used for added grain, grain is fed in the milking parlor, grain is just spread on top of a forage in a feed bunk and not really mixed in, or cows are out on pasture at some time during the day.

Total mixed rations help dairy cows achieve maximum performance and are the most common method for feeding high producing, indoor-housed dairy cows in the world. The dairy farmers struggling to tackle the rapidly increasing feed cost, the recent introduction of Total Mixed Ration (TMR) can effectively reduce the feed cost by inclusion of wet by products like brewers grain, tapioca starch waste, fruit industry by products etc., and low quality roughage like maize stover, gram husk etc. The TMR, which consists of mixing of roughage and concentrates in correct quantity and proportion along with the supplements. Milk production and milk components give profit to dairy farmers, improving DMI especially in early and high-producing cows is required to get that done. Wachirapakorn et al. (1997) compared two feeding regimes (Conventional and TMR feeding) found that TMR feeding increase the dry matter intake (DMI) and milk production compared to conventional feeding.

Introduction——

Feeding a total mixed ration (TMR) helps a dairy cow achieve maximum performance. Since its inception in the 1950s, it is now the most adopted method for feeding high producing, indoor-housed dairy cows in the world. This is accomplished by feeding a nutritionally balanced ration at all times, allowing cows to consume as close to their actual energy requirements as possible and maintaining the physical or roughage characteristics, which we now refer to as feed particle size, required for proper rumen function. Advantages and disadvantages of any feeding system, however, must be weighed before choosing a TMR.

Good feeding management practices must be followed to achieve maximum performance from cows. First, monitor forage and feed inventory on a regular basis and allocate to the appropriate animal group. Second, test forages and feeds several times throughout the year or when any noticeable change occurs. Lastly, update ration formulations based on milk production, milk fat and milk protein percent, current body weight and body condition scores, moisture changes in forages or high moisture feed ingredients, and prices of current feeds. Checking forage moisture on a frequent basis is critical to implementing a successful TMR system.

There are several strategies that can be used in TMR systems. Separate TMR can be developed for different animal groups. These can be formulated for fresh cows, early lactation cows, and mid- and late-lactation animals, as well as for far off and close-up dry cows. Such multi-group strategies are particularly helpful for meeting the needs of dry cows. One group TMR, on the other hand, can be used for lactating cows with or without top-dress feeding. Cows can be grouped based on actual or fat-corrected milk, days in milk, reproductive status, age, nutrient requirements, and health.

Advantages of a TMR Feeding System———-

Improved feeding efficiency often occurs with herds using a TMR. Each mouthful of feed that the cow consumes contains the proper amount of ingredients for a balanced ration, resulting in a more stable and ideal environment for the rumen microbes and providing adequate carbohydrates and nitrogen sources that vary in their ability and rate of rumen breakdown. This in turn can lead to production of higher levels of microbial protein by the rumen microbes throughout the entire 24-hour day. A 4% increase in feed utilization can be expected when using a TMR compared to a conventional ration of forage and grain fed separately, twice daily. In addition, the ability to use feeds with various rates of breakdown is enhanced, often enabling even better nutrient utilization. Farmers can also utilize a greater variety of byproduct feeds with a TMR, thereby allowing for possible ration cost savings. The incidence of digestive and metabolic problems often decreases when a TMR is fed, and milk production has been shown to be as much as 5% higher with a TMR compared to conventional rations as a result of these benefits.

A TMR provides greater accuracy in formulation and feeding if managed properly. Using feed scales both on mixing equipment in a feed area allows the quantity of each ingredient fed to be closely controlled. When a TMR is mixed properly, a cow cannot consume significantly more or less of a forage or concentrate than planned in the ration formulation. Parlor and selective feeding can be discontinued or limited to token amounts to facilitate cow movement, unless specific milking systems such as robotic milking systems are being used. The TMR system is well adapted to mechanization with a mixer wagon or a stationary mixer with conveyors or mobile feeders. Mixing equipment must be properly maintained and load cells and scales must be kept in accurate working order. Mixers can be purchased that handle the addition of long hay, however these are seldom recommended. Many of the TMR mixers that chop long forage also break down other feed and silage particles while they are reducing the long hay particle size. The result is often that the entire TMR has reduced particle size as a result of attempting to add a few pounds of long dry hay to the mix. It is most always recommended to chop long forage as a separate commodity before adding it to the TMR mixer and mix for a limited amount of time as recommended by the manufacturer. This generally is no more than 4 to 5 minutes–just long enough to achieve a good mixture.

Commodity ingredients can be fed quite effectively in a TMR diet. Both unique and common types of commodities are often less expensive due to bulk handling and direct purchasing. However, quality control must be maintained when purchasing commodity feeds. This often entails additional feed analysis, but additional costs of transportation and handling required by a commercial feed manufacturer are avoided. The quantity of commodity feeds purchased depends on rate of spoilage, level of use, and available storage space. Purchasing large quantities may not be economical due to increased inventory costs. Total feed losses for commodity feeds, including what occurs during storage and handling, can range from 3% for a dry grain product to 15% for a high-moisture product such as wet brewers grain. Purchasing should be based on quality and nutrients needed for the ration, not solely on price. Additionally, a greater variety of ingredients allow more flexibility in formulating the ration for various production groups.

One of the major advantages of blending all the feeds together in a TMR is that it can mask the flavor of less palatable feeds. Feeds such as urea, limestone, fats, and some by-pass protein sources may be less palatable. However, through blending, they can be added to TMR in reasonable amounts with little to no reduction in feed consumption.

Disadvantages of a TMR Feeding System———-

Mixing or blending devices needed for the ration require small to moderate expenditures for equipment and maintenance. Further, it is important to follow the manufacturer’s recommendations for mixing. Over mixing can cause serious problems due to grinding and pulverizing the feed. Under mixing can result in less effective feed utilization by the cows.

Accurate weighing with calibrated scales, which also may involve additional cost and maintenance, is essential. Care must be taken in formulating and mixing the ration. If the diet is not balanced correctly or mixed properly, the cow ultimately will suffer reduced performance. While this is true of any feeding system, it is under the control of the person feeding the herd. Remember with a true TMR, cows have no other option for a diet and depend solely on the ration for a balanced diet to achieve production and health.

In some cases, existing buildings, feed alleys, and mangers may make a TMR system nearly impossible to use. Some housing and feeding facilities may just not be well suited for a TMR system. Further, it may not be economical for all herds, particularly small herds or those using pasture feeding over an extended period of time, to implement a TMR system due to the increased cost of the feeding system per animal-day it is utilized.

Feeding Management on TMR Systems———–

Forages should be chopped properly before ensiling. Most forage particles in silage and haylage should range from 3/8 to 3/4 inch in length. Forage particles that are very fine, or grain that is too coarse or whole, should be avoided in the ration. Cows generally sort against long particles due to their less palatable nature and sort for finer particles in the ration. This behavior can lead to metabolic problems such as subacute ruminal acidosis (SARA). Cows consuming the finer particles of the ration are reducing their particle size consumption and, in effect, their NDF intake. These sorted diets contain more fermentable carbohydrates and less effective fiber than the formulated ration. Effectively a sorted TMR is not a balanced TMR, and much of the time, effort, and expense involved in making the TMR is lost when it is sorted by the cow.

It is imperative to develop rations based on current forage analysis reports. Current recommendations are to take the average of at least two separate and independent forage analyses from the same lab before building a TMR. Make ration adjustments when a change in forage is observed; again, this should be based on more than one sample and forage analysis. The dry matter of ensiled material should also be checked frequently. A change in dry matter can alter the TMR drastically, and these changes usually are more long term and progressive. Accuracy of the scales and mixing system is critical to a TMR system, and a regular maintenance schedule should be planned and executed.

Determining the actual dry matter intake of cows often helps to indicate problems with forage quality and dry matter content. Cows should be within 5% of the expected dry matter intake. If actual dry matter intake exceeds 5% of the expected, that ration should be reformulated. Extremely low intakes may indicate that forage quality and/or dry matter contents have changed and may be a limiting factor to intake.

The number of animal groups to have in a TMR system is determined by the existing herd size and layout of the barns and loafing areas. An ideal TMR system for an entire farm could have seven main groups: high, medium, and low production lactating cows, far-off and close-up dry cows, and prebreeding and postbreeding heifers. In addition, many herds separate a first-lactation cow group from older cows for all or part of the first lactation. On many farms this group is critical, especially if other cow groups are overcrowded. First lactation cows most often respond well if they are undercrowded in terms of feed bunk and resting space per animal. Depending on farm size, having this many separate groups may be unrealistic, yet larger farms may have multiple groups of each.

When working with a one- or two-group TMR system, there is less flexibility to formulate rations to meet specific needs. For instance, the lower-producing cows receive the same forage as the higher-producing cows, which may not allow for optimal use of various forages. In a three-group system, low-group cows can usually be fed cheaper forage to reduce costs. Using a one-group TMR system usually results in higher feed costs because more expensive ingredients such as undegradable protein sources, fats, and certain feed additives are fed to cows in later stages of lactation. These cows should be fed a ration with higher levels of forage than a one-group TMR would provide. Lower-producing cows may become over conditioned in a one-group TMR system. Many of the problems of the one-group system can be avoided by using two groups, especially if one of them is fed according to above average group production. Obviously cow movement and changing social orders within pens is another factor to be considered when deciding the best number of groups for a farm operation. There is no one perfect answer for all systems and some farms will vary the number of TMR groups from year to year to best match other situations and priorities on the farm. The larger the farm, the easier it is to have the larger number of groupings or ration changes throughout the lactation cycle.

Dry cows, in particular, are often recommended to be divided into two groups, far-off and close-up. Using a two-group TMR system for dry cows can minimize the level of metabolic and nutritional disorders observed at calving and in the postpartum period. The close-up group should be cows two or three weeks from calving, or if it is being balanced for anions and cations, three to four weeks.

To ensure proper ration formulation for growth and development, a two-group TMR system is necessary for heifers with the inclusion of one prebreeding and one postbreeding heifer group. Young heifers lack the capacity to consume very high forage diets while maintaining proper growth. It is necessary for prebreeding heifers to have an energy- and protein-dense diet.

There are other points to consider when feeding a TMR. First, the ration should be available to the cows 22 to 24 hours daily. To promote maximum feed intake it is often recommended that refusals for the fresh group remain around 2 to 4%, 1 to 3% for high groups, and 0.5 to 3% for late-lactation groups. In general, feed refusal should not exceed 3 to 4%. Feed refusals can be fed to older heifers, steers, or other beef cattle. Refusals should never be fed to prefresh or fresh cows. First-calf heifers should be placed into a higher group than their production level to compensate for growth that they will have in the first lactation. Placing first-lactation heifers in a group separate from older cows reduces competition and gives younger cows improved access to bunk and stall space. Second, if hay or grain is fed separate from the TMR, it should be limited to two to five pounds per head per day. Supplemental grain feeding to high producers may be necessary in one-group TMR systems. However, the amounts to feed will depend on the level of concentrate that is being fed in the TMR. When large quantities of feedstuffs are fed separately from the TMR, the TMR loses many of the advantages it has over conventionally fed rations. Therefore, if possible keep all or nearly all of the ingredients in the TMR to maximize performance and profit.

General Approach to Formulating TMR———-

The key to formulating TMR is to optimize dry matter intake. Total dry matter intakes should be consistent with production and breed (see Table 1). Intakes may be depressed when ensiled materials undergo abnormal fermentation. Forage dry matter should consist of good- to excellent-quality forages, especially for high-producing animals. Palatability of forages, the presence of certain weeds, and water quality can affect intake. Dry matter intakes may be elevated when forage is chopped too finely or excessive concentrate dry matter is present. Dry matter intake during the first two weeks post calving may average 2% of body weight.

Table 1. Expected daily intakes of total dry matter by dairy cattle.

Milk production,

4% FCM (lbs/day) Dry matter intake

(% of body weight)

Large breeds Dry matter intake

(% of body weight)

Small breeds

100 4.30 5.80

90 4.10 5.40

80 3.80 5.00

75 3.65 4.80

70 3.50 4.50

65 3.40 4.25

60 3.25 4.00

55 3.13 3.85

50 3.00 3.70

45 2.85 3.50

40 2.70 3.30

35 2.60 3.10

30 2.50 2.90

20 2.10 2.50

The ration differences between groups should be minimal, otherwise cows will decrease milk yield significantly when they are moved to a different group. Limit differences in concentrate dry matter proportions to not over 10 to 15% between groups. The level of concentrate dry matter and protein depends to a certain extent on the production level and the type of forage used (see Table 2).

Table 2. Guide to ration composition for high-producing cows.a

Stage of Lactation

Earlyb Stage of Lactation

Midc Stage of Lactation

Late

aRefers to milk production equivalent to a DHI rolling herd average of 24,000 lb of 4% fat-corrected milk or higher.

bRefers to cows in approximately the first 15 weeks of lactation. If cows fresh less than 4 weeks are kept in a separate group or fed individually, or founder is encountered in first-calf heifers, use the following modified specifications: CP 19%, UIP 38%, NEL 0.76%, forage NDF 24%, fat 3 to 5%, the higher levels of minerals indicated and approximately 50% concentrate dry matter. DMI during the first month may range from 2.2% BW at calving to 2.8% BW at 14 days and 3.3% at 30 days.

cFollow guidelines for mid lactation animals if a one-group TMR is being fed.

dUse more than one high protein supplement to meet undegradable protein needs (UIP). Often lysine and sometimes methionine are the most limiting essential amino acids. On a largely corn-based ration as silage, grain or corn by-products; part of the UIP should be furnished by animal or fish protein, soybean protein or cottonseed protein to provide more lysine. Limit use of brewers, distillers, corn gluten meal, and feather meal in high corn diets.

eNEL needs are dependent upon production level, body condition scores, and deviations in dry matter intake.

fFat at over 5% should be furnished by rumen-inert or by-pass fats.

gUse these minerals at the higher level indicated when fat content exceeds 4.0%.

hUse the higher potassium level during periods of hot, humid weather.

iUse the higher copper levels when low serum copper occurs on rations containing usual levels of 10 to 12 ppm. Induced copper deficiency may result from excessive intake of iron, manganese, molybdenum, and sulfur.

jWhen feeding total mixed rations avoid differences between rations that exceed 10 to 15% for milking groups to avoid excessive drops in production when moving to a lower group.

Crude protein, %DM 17 to 18 16 to 17 15 to 16

Soluble protein, %CP 30 to 34 32 to 36 32 to 38

Degradable protein, %CP 62 to 66 62 to 66 62 to 66

Undegradable protein, %CPd 34 to 38 34 to 38 34 to 38

NEL, Mcal/lb DMe 0.76 to 0.80 0.72 to 0.76 0.68 to 0.72

Forage NDF, %DM 21 to 24 25 to 26 27 to 28

Total NDF, %DM 28 to 32 33 to 35 36 to 38

NFC, %DM 32 to 38 32 to 38 32 to 38

Fat, maximum, %DMf 5 to 7 4 to 6 4 to 5

Calcium, %DMg 0.81 to 0.91 0.77 to 0.87 0.70 to 0.80

Phosphorous, %DMg 0.40 to 0.42 0.40 to 0.42 0.40 to 0.42

Magnesium, %DMg 0.28 to 0.37 0.25 to 0.34 0.22 to 0.28

Potassium, %DMh 1.00 to 1.50 1.00 to 1.50 1.00 to 1.50

Sulfur, %DM 0.23 to 0.24 0.21 to 0.23 0.20 to 0.21

Salt, %DM or 0.45 to 0.50 0.45 to 0.50 0.45 to 0.50

Sodium, %DM 0.20 to 0.25 0.20 to 0.25 0.20 to 0.25

Chlorine, %DM 0.25 to 0.30 0.25 to 0.30 0.25 to 0.30

Manganese, ppm 44 44 44

Copper, ppmi 11 to 25 11 to 25 11 to 25

Zinc, ppm 70 to 80 70 to 80 70 to 80

Iron, ppm 100 100 100

Added selenium, ppm 0.3 0.3 0.3

Added cobalt, ppm 0.2 0.2 0.2

Added iodine, ppm 0.5 0.5 0.5

Total vitamin A, IU/lb DM 4,500 4,500 4,500

Added vitamin D, IU/lb DM

Minimum 750 750 750

Maximum 1,100 1,100 1,100

Total vitamin E, IU/lb DM 30 30 30

Approximate concentrate, %DMj 55 to 60 45 to 50 35 to 40

Approximate DMI, %BW 4.0+ 3.5+ 3.0+

Moving cows through groups in multi-group systems may control body condition in herds fed a TMR. In single-group TMR systems, the percentage of concentrate dry matter may be altered; thin cows could receive supplemental feed and over-conditioned cows could be somewhat limited in amounts of the ration fed. In general, it is important to follow sound nutrition practices with respect to crude protein, energy, neutral detergent fiber, nonfiber carbohydrates, fat, macro and micro minerals, and vitamins for the respective levels of production. Monitoring intakes of the TMR is beneficial so that animals do not over- or under-consume.

Dry cows, in particular, may need at least five pounds of long-stem hay along with a TMR to provide sufficient “effective fiber.” Dry cows placed on a close-up TMR should be kept on the ration until the day they freshen. This applies to both regular and anionic close-up rations (see Table 3). Dry cows that are not grouped and offered one TMR may be fed limited amounts of the milk cow TMR two or three weeks prior to freshening. However, restrictions must be set to ensure that there is adequate forage dry matter intake and that the nutrient densities of protein, minerals, and vitamins do not exceed recommendations for close-up dry cows.

Table 3. Guide to ration composition for dry cows.

Far-off Close-up, regulara,b Close-up, anionica,c

aThe last three to four weeks prior to expected calving.

bRegular or cationic (alkaline) diet.

cAnionic or acidic diet with a cation-anion balance of -100 to -150 milliequivalents per kilogram (mEq/kg). This is based on the simple equation of: mEq/kg = mEq (Na+K) – mEq (Cl+S). Factors to convert from nutrient % to mEq/kg of diet are Na: 435, K: 256, Cl: 282, and S: 624. Example: Calculate the cation-anion balance of a ration with Na at 0.15%, K at 1.10%, Cl at 0.80%, and S at 0.40% (all values are on a dry matter basis). mEq/kg = [(0.15 x 435) + (1.10 x 256)] – [(0.80 x 282) + (0.40 x 624)] = (65.3 + 281.6) – (225.6 + 249.6) = 346.9 – 475.2 = -128.3

dSulfur level of 0.45% in the close-up anionic diet may be tolerated for short periods of time (three to four weeks).

eUse the higher or intermediate levels when an induced copper problem exists due to high iron, manganese, molybdenum, or sulfur intakes.

Crude protein, %DM 12 to 13 13.5 to 14.5 13.5 to 14.5

Soluble protein, %CP 30 to 38 30 to 38 30 to 38

Degradable protein, %CP – – –

Undegradable protein, %CP – – –

NEL, Mcal/lb DM 0.60 to 0.64 0.62 to 0.66 0.63 to 0.67

Forage NDF, %DM 27, min 27, min 27, min

Total NDF, %DM 36, min 36, min 36, min

NFC, %DM 26, min 26, min 28, min

Fat, maximum, %DM – – –

Calcium, %DM 0.45 to 0.55 0.45 to 0.55 1.40 to 1.60

Phosphorous, %DM 0.30 to 0.32 0.30 to 0.32 0.32 to 0.35

Magnesium, %DM 0.24 to 0.28 0.28 to 0.32 0.28 to 0.32

Potassium, %DM 0.80 to 1.00 0.80 to 1.00 0.80 to 1.10

Sulfur, %DMd 0.16 to 0.17 0.17 to 0.19 0.35 to 0.40

Salt, %DM or 0.25 to 0.30 0.25 to 0.30 0.25 to 0.30

Sodium, %DM 0.10 to 0.12 0.10 to 0.12 0.10 to 0.12

Chlorine, %DM 0.20 to 0.24 0.20 to 0.24 0.70 to 0.80

Manganese, ppm 44 44 44

Copper, ppme 11 to 25 11 to 25 11 to 25

Zinc, ppm 70 to 80 70 to 80 70 to 80

Iron, ppm 100 100 100

Added selenium, ppm 0.3 0.3 0.3

Added cobalt, ppm 0.2 0.2 0.2

Added iodine, ppm 0.5 0.5 0.5

Total vitamin A, IU/lb DM 3,500 3,500 3,500

Added vitamin D, IU/lb DM

Minimum 750 750 750

Maximum 1,100 1,100 1,100

Total vitamin E, IU/lb DM 35 35 35

Approximate concentrate, %DM 12 to 15 22 to 25 22 to 25

Approximate DMI, %BW 2.0 1.8 1.8

Nutrient specifications for heifer TMR are in Table 4. Total dry matter intakes are regulated by the bulk of the ration and its energy density. If corn silage is fed heavily in a heifer TMR, intakes may have to be controlled and more closely monitored to avoid over conditioning.

Table 4. Guide to ration composition (on a dry matter basis) for dairy replacement heifers.

0 to 6 Mo. 7 to 11 Mo. 12 to 24 Mo.

aUse higher or intermediate copper levels when an induced copper problem exists due to high iron, manganese, molybdenum, or sulfur intake.

Crude protein, %DM 16 13 12

Soluble protein, %CP 25 to 30 30 to 35 30 to 38

Degradable protein, %CP 45 to 55 33 to 37 25 to 30

Undegradable protein, %CP 45 to 55 63 to 67 66 to 72

NEM, Mcal/lb DM 0.77 0.72 0.65

NEG, Mcal/lb 0.49 0.44 0.38

TDN, %DM 69 66 63

Total NDF, min., % 25 30 35

Calcium, %DM 0.60 0.48 0.45

Phosphorous, %DM 0.40 0.32 0.30

Magnesium, %DM 0.22 0.22 0.22

Potassium, %DM 0.80 0.80 0.80

Sulfur, %DM 0.21 0.17 0.16

Salt, %DM or 0.25 to 0.30 0.25 to 0.30 0.25 to 0.30

Sodium, %DM 0.10 to 0.12 0.10 to 0.12 0.10 to 0.12

Chlorine, %DM 0.20 to 0.24 0.20 to 0.24 0.20 to 0.24

Manganese, ppm 44 44 44

Copper, ppma 11 to 25 11 to 25 11 to 25

Zinc, ppm 70 to 80 70 to 80 70 to 80

Iron, ppm 100 100 100

Added selenium, ppm 0.3 0.3 0.3

Added cobalt, ppm 0.2 0.2 0.2

Added iodine, ppm 0.5 0.5 0.5

Total vitamin A, μ/lb DM 2,500 2,500 2,500

Added vitamin D, μ/lb DM 400 400 400

Total vitamin E, μ/lb DM 35 35 35

Approximate concentrate, %DM 60 to 65 20 to 25 10 to 15

Approximate DMI, %BW 2.6 2.2 1.7

The benefits of using a TMR far outweigh the disadvantages, but each farm has different goals and facilities that may or may not adapt well. Each case should be analyzed to find the most profitable alternative. A carefully designed and well thought-out system will pay off in the long run.

TMR Feeding:—————————

Milking cows need quality feed available 20 hours of a day. The TMR can be fed twice in a day, once in the early morning and once in the evening keeps the feed fresher and increase feed intake. TMR machine pushed up feed in front of the cows to stimulate feed intake. When increasing or decreasing the amount of TMR fed. the amounts of each forage, grain, and other ingredients need to be increased in proportion to the originally formulated TMR. Samples should be collected at the beginning, middle, end of the feed delivery, and residual feed in the feeder should be evaluated. These results need to be compared to detect any potential problems. When increasing or decreasing the amount of TMR fed, the amounts of each forage, grain, and each of the other ingredients need to be increased in proportion to the originally formulated TMR

Dry Matter Content of TMR———

The balanced rations for dairy cattle, that the cow will receive a certain amount of dry matter from a particular feed. The dry matter content of silages and wet byproducts is vary. As the feed becomes wetter, more feed to be included and as feeds become drier, less of the forage or feed needs to be included in the TMR. The optimum dry matter content of TMR is about 50-60%. The dry matter content of TMR is more than 60% dairy cattle selectively consume (sort) smaller concentrate particles than long forage in the ration. Water addition to a dry TMR as a technique to reduce the degree of feed sorting (Shaver, 2002). Sorting will be increased when adding water to a higher-moisture TMR (58-48%) due to filling effect of the ration (Miller-Cushon and DeVries, 2009)

Estimation dry matter intake———––

General

DMI (kg/day) = [1.8% x body mass (kg)] + [4% FCM (kg) / 3]

where: 4% FCM = (0.4 x kg milk) + (15 x kg fat) (source: University of Minnesota)

Early lactation

DMI (kg/day) = [0.01641 x bodymass (kg)] + [0.1713 x kg daily milk yield] + [4.534 x daily fat yield]

Mid lactation

DMI (kg/day) = Early lactation DMI x 1.07 (source: University of Wisconsin)

late lactation

DMI (kg/day) = [0.0185 x bodymass (kg)] + [0.305 x 4% FCM (KG)] (source: University of Georgia)

If the expected and actual intake differ by more than 5 to 10% ration should be reformulated.

Table.1 Nutrient concentrations in total mixed rations for Lactating and Dry cows

Nutrients Stage of lactation Dry cows

Fresh

(0-21 days) Early

(21-120 days) Mid

(120-220 days) Late

(>220 days) *Early Dry **Close to Calving

DM intake (kg)

Holstein-Friesland 18 25 22 19 13 11

Jersey 14.5 18 16 15 10 9

Protein (% DM) 13 18-19 16 14 13 15

Protein degradability (%) 56 60 64 68 70 60

ME (MJ/kg DM) 11.0-11.4 11.4-11.7 10.7-11.1 10.1-10.7 8.5 9.2

ADF (% DM) 20 19 21 24 36 30

NDF (%DM) 30 28 32 36 48 42

NSC (% DM) 35 40 37 34 30 33

Fat (% DM) 5 7 5 3 2 3

Ca without added fat (% DM) 0.8-0.9 0.8-0.9 0.6-0.8 0.6-0.7 0.6 0.7

Ca with added fat (% DM) 1.1 1.18 0.8-1.0 0.7-0.8 – –

P (% DM) 0.55 0.5-0.55 0.46 0.40 0.30 0.35

Mg (% DM) 0.3 0.3 0.3 0.3 0.16 0.20

Se (mg/day) 8 8 8 8 8 8

* Early dry period is from drying off to two weeks pre-partum

** Close to calving refers to last 2 weeks pre-partum to 2 days post-partum Close to calving refers to last 2 weeks pre-partum to 2 days post-partum Close to calving refers to last 2 weeks pre-partum to 2 days post-partum

NSC : RDP ratio———-

The Non Structural Carbohydrate (starch, sugar) in the diet provides the energy required for microbial protein synthesis. When high levels of NSC are fed with Ruminally Degradable Protein (RDP) can limit microbial growth. The diets should be formulated to provide 35 to 40% NSC and 60 to 65% of the protein as RDP.

Particle Size of TMR————–

Cows need to consume adequate amounts long forage fiber for cud chewing and more saliva, which helps buffer the rumen environment so that the bacteria can efficiently digest forages. When a TMR mix is over mixed, the particle size of the forages decreases, result in, decreases cud chewing time and saliva production, which lead to an increased incidence of ruminal acidosis, laminitis. Generally, TMR mixing time is about three to six minutes.

The particle size of the TMR will be evaluated using a Penn State particle separator box (see Figure 1). This separator box consists of three separate boxes that allow the TMR mixture to be separated into three particle sizes. The top box retains particles of feed or forage that are greater than 0.75 inch. The middle box retains particles between 0.31 and 0.75 inch. The bottom box has a solid bottom and retains particles less than 0.31 inch. Expected percentages retained on each of the three boxes are shown in Table 2.

Table.2 Distribution of total feed particles (%) in the Penn State Particle Separator Box.

Forage or Feed Top (0.75 inch) Middle (0.31 to 0.75 inch) Bottom (<0.31 inch)

TMR 5-15% 40-50% < 50%

Corn Silage 2-10% > 50% < 50%

Haylage 10-20% 30-50% < 45%

Grouping of dairy animals for TMR Feeding—————-

Dairy herds feeding a TMR should have a minimum of 3 milk production groups and 2 dry cow groups. The groups are following:

1. Pre-Fresh or close-up dry cows (2 to 3 weeks before calving).—————–

The dry matter intake of this group is about 10 kg/day. This group of animal require more fiber in the ration and contains all the nutrients required to prepare for the birth calf, initiation of lactation and help to prevent metabolic problems. This ration should contain about 3 kg of grain, 2 to 3 kg of good quality hay plus forage like corn silage and the proteins, minerals and feed additives needed to make the ration.

2. Fresh cow group (1 to 21 days after calving). These cows have a low dry matter intake, but a high nutrient requirement as they begin the lactation. The ration should contain adequate fiber (2 to 3 kg of good quality hay) to help promote good rumen function plus other forages and concentrates to start high milk production.

3. High producing older cow (2nd lactation and above) group (21 to 180 days in milk).

This group require more dry matter for peak milk production and breeding.

4. First lactation or first calf heifer group.

They are slower to reach peak dry matter intake and milk production, but more persistent than older cows. This group can stay for 250 days in milk or more before moving to a late lactation group.

5. Mid-lactation cows (180 to 250 days in milk).

Cows in this group should be pregnant and milk production should average 75 to 85% of the high group. The ration fed to this group should be higher in forages and slightly less nutrient dense than the high group ration.

6. Late lactation pregnant cow group (250 days in milk to dry off).

The first lactation cows, over 250 days in milk, can be mixed with older cows for the entire lactation. The ration will be high in forage towards maintaining milk production and avoiding over conditioning or fattening cows.

7. Far-Off dry cows (220 to 260 days pregnant).

The goal of the dry period should be to prepare the cow for the next lactation. The TMR should contain good to medium quality forages to promote maximum rumen fill, Adequate protein and mineral balance in the ration is required.

Advantages of a total mixed ration

• Increased dry matter intakes (DMI). Peak DMI is achieved 4 to 8 weeks earlier than conventional systems.

• All forages, grains, protein supplements, minerals and vitamins are thoroughly mixed.

• Selective feeding can be reduced.

• Totel mixed ration formulated according to stage of lactation and milk yield.

• Each mouthful of feed consume by the cow contains balanced ration.

• TMR increase feed efficiency, compared to a conventional ration.

• The incidence of digestive and metabolic problems decrease.

• The milk production can be increased with TMR compared to conventional methods.

• The TMR system is well adapted to mechanization with either a mixer wagon, cart or a stationary mixer with conveyors or mobile feeders.

• Variety of ingredients is used to make total mixed ration.

1. Cows Can’t Pick and Choose What They Eat

• You can hide less palatable feed ingredients within a TMR.

• You don’t have some cows that eat mostly hay and others eating mostly grain.

•

• 2. Synchronization of Carbohydrate and Protein Availability in the Rumen

• Rather than having protein fed at one hour, energy fed an hour later, and hay crop silage fed two hours after that, with a TMR, protein, energy, and fiber are supplied to the rumen microbes at the same time. The rumen microbes reproduce very rapidly and require nutrients in a specific ratio throughout the day. Microbial growth and microbial protein synthesis can increase by feeding a TMR rather than feeding ingredients individually because of a more uniform supply of nutrients.

•

3. Less Acid Build-Up in the Rumen

• Acidosis is caused by the accumulation of acid and the reduction in pH of the rumen contents. Grain generates large amounts of acid and fiber is needed to stimulate saliva production. Saliva buffers the rumen. It reduces rumen acidity (increases rumen pH). With a TMR, grain is consumed in many small meals throughout the day rather than in 2-4 larger meals as is the case with component feeding. Fiber is also consumed in many smaller meals. TMR’s help to increase the average rumen pH throughout the day, especially minimizing dramatic variation in rumen pH during the day.

•

ADVANTAGES FOR THE DAIRY FARMER———————

1. A TMR may save labor because there will be less trips to make around the barn (in the case of a tie-stall barn). A TMR will save time spent in the parlor if the cows don’t need to be fed grain there.

2. TMR’s may facilitate the use of commodity feeds such as wet brewer’s grains and whole cottonseed that are more difficult to handle. This may reduce feed cost.

Disadvantages of the total mixed ration———-

• Grouping of cows is not feasible in small herds (less than 50 cows). If not grouped according to production, cows in late lactation are likely to get fat.

Additional equipment is needed to chop the hay or straw before being added to the TMR mixer.

DISADVANTAGE OF A TMR FOR THE COW

Cows Are Not Fed as Individuals—-

• With a TMR, all cows in a group get the same ration. Often, with component feeding, high producers are supplemented with extra grain and cows that are off-feed are given less grain and perhaps some extra hay. This individual attention is eliminated with a TMR.

• Unfortunately, on farms without the facilities for many groups, cows are often too fat or too thin. This is evidence that some cows got too much grain and others didn’t get enough. This is especially true on farms with only one milking ration (one-group TMR). This situation not only compromises production but it is also inefficient and costly, especially for lower production herds (less than 80 pounds (36 kg) /cow/day) that are not milking three or four times per day and are not using bST.

• On farms with only 2 or 3 milking rations, cows sometimes drop in milk production when they are moved from a group balanced for a higher level of milk production to a lower production group. This is a nutritional problem as well as a social problem. Social problems can be minimized. Move groups of cows instead of moving one cow at a time. Move cows at a time of day when social interactions will be minimized (i.e. after evening milking rather than after morning milking). Nutritional problems can be reduced by having no more than a 20-pound (9 kg) spread in the milk production support between rations and by keeping the protein content a little higher than that needed to support the level of production in the lower group.

With a Total Mixed Ration (TMR) every mouthful of feed that the cow eats is a balanced ration. A ration is not a TMR if: hay is fed separately, a computer feeder is used for added grain, grain is fed in the milking parlor, grain is just spread on top of a forage in a feed bunk and not really mixed in, or cows are out on pasture at some time during the day.

DEVELOPMENT OF A TMR FOR A GROUP OF COWS-——

1. Determine average body weight, milk production, and fat test of the group. Determine the realistic, desired amount of milk production to balance the ration for.

2. Evaluate body condition of the cows in the group. If necessary, increase or decrease the energy content of the ration according to body condition needs.

3. Estimate dry matter intake and forage NDF intake. Determine the amounts of individual forages to be fed on a dry matter basis (based on quality and inventory). Remember that cows eat pounds of nutrients, not percentages of nutrients. The nutrients must be provided in a package size that the cow can eat.

4. Formulate the grain and mineral supplements to meet the nutrient needs of the cow beyond the nutrients supplied by forages.

DAY TO DAY TMR FEEDING——

1. Feed forages and wet ingredients on a dry matter basis. Monitor changes in dry matter content of silage and wet by-product ingredients. A moisture tester is a good investment and should be used at least weekly and when there is an obvious change in the forage being fed. A TMR should supply a consistent amount of dry matter from forages in a balanced diet. So, if the moisture content of forage increases, more pounds of As-Fed forage should be fed but the pounds of forage dry matter should remain the same. A change in the size of a mixer load or a change in TMR refusals by the cows should alert feeders to a change in forage dry matter, but it is preferable to correct weights before feeding an incorrect ration for a few days and suffering milk production losses. During vvariable weather conditions, some farmers will feed a consistent volume of each silage and rely less on silage weight.

2. Keep track of the number of cows in the group and adjust the amount fed according to the number of cows in the group.

3. Increase or decrease the total mix fed according to daily intake levels — Move all feeds up or down in proportion. The easiest way to figure this is to feed for more or less numbers of cows in a group. If intake is consistently more than 5% higher or lower from that predicted (and that balanced for), work with your nutritionist to adjust the ration accordingly.

4. Keep the TMR fresh. Don’t let the TMR sit around before feeding, especially during hot weather.

GROUPING STRATEGY—-———

Pre-Fresh Cows: (2-3 weeks before calving up to calving day)——————-

• These cows have low dry matter intakes (about 23 pounds (10.5 kg) /day for large breeds) but increased protein and energy requirements because of the impending lactation as well as the large calf growing inside. This ration should be used as a transition to the fresh cow ration. The goal is to supply the needed nutrients and to adjust the rumen microbes and the rumen papillae (which absorb acids from the rumen) to a diet that contains more grain while at the same time maintaining rumen function during a time of low and fluctuating daily dry matter intake. The diet should contain 32-34% NFC (usually 7-8 pounds (3-3.5 kg) of grain) plus long, effective fiber. Five pounds (2.25 kg) of hay included in the ration is very helpful. The mineral balance of this ration is also critical for avoiding milk fever. Close attention should also be paid to ration palatability.

•

Fresh Cows: (0-30 DIM)———————–

• These cows have lower intakes but high nutrient requirements. A primary goal is to provide the nutrients needed to drive the cow towards high peak milk production while maintaining rumen function and preventing metabolic disorders (D.A.’s, ketosis, acidosis).

• Often fresh cow rations are formulated with a slightly higher level of forage NDF than the high group ration. The inclusion of long hay (4-5 pounds (2 kg)) is also very helpful. Additives such as calcium propionate, niacin and rumen protected choline are often added to fresh cow rations to help cows experiencing some degree of ketosis. Money is well spent in this group because it should pay off for the entire lactation.

•

High Cows: (30-150 DIM)———————

• Most of these cows should be near peak feed intake and peak milk production. The goal is to maintain high milk production and to get cows bred back at this time. Close attention should be paid to maintain adequate effective fiber in this ration that is balanced for high milk production.

•

First-Calf Heifers:—————-

• First-calf heifers generally respond in milk production if they are in their own group. This is due to social as well as nutritional reasons. Rations for first-calf heifer groups are balanced for less dry matter intake and support slightly less milk production than the high group ration. If first-calf heifers are smaller than mature cows and they are grouped separately, expect 5-10% more milk over the lactation. The ultimate goal in today’s high-producing herds, however, should be to grow large, well-framed heifers so that there is less need for a first-calf heifer group.

•

Medium Cows: (150-210 DIM)————————-

• These cows should be bred and milk production will be declining. Underfeeding these cows will lead to irrecoverable milk losses. Overfeeding will be a waste of money and result in overconditioning which will be a problem when cows begin their next lactation. The goal with this group should be to maintain milk production as economically as possible. Often, if farms have a first-calf heifer group, they used the medium group for tail-end first-calf heifers.

•

Tail End Cows: (210-305 DIM)——————-

• These cows have low nutrient requirements that can mostly be supplied by forages. A primary goal is to avoid overconditioning at this time.

•

Dry Cows:—————————–

• The goal of the dry period should be to prepare the cow for the next lactation. Avoid overconditioning (using medium quality forages) and rejuvenate the rumen preferably through the provision of long hay. Adequate protein and a proper mineral balance should be supplied.

The number of groups used on a particular farm will depend on factors such as, the size and configuration of barn, the number of cows on farm, milking parlor and holding area constraints, milk production level of herd, and labor constraints.

OTHER FACTORS TO KEEP IN MIND WITH A TMR

Scale Calibration————–

Check mixer wagon scales routinely. Scales should be calibrated when there is a lot of weight in the mixer as well as when it is empty. Many people find it easiest to place a known weight, such as a 50-pound bag of feed, on the corners of the wagon to test each load cell. Consult the mixer wagon manual for manufacturer’s recommendations.

Add TMR Ingredients in the Proper Order and Don’t Overmix——————-

It is important to maintain length of forage fiber in your TMR. Generally, it is recommended that the haycrop silage, long hay, or other long fiber sources be added last, unless the mixer is equipped with at hay processor (then the hay must be added first). With auger mixers, a mixing time of 5 minutes should be enough. Fifteen to twenty minutes is too much. Again, consult the mixer wagon manual for manufacturer’s recommendations. If you are wondering how much your long fiber is reduced in the mixer wagon, mix a small TMR in the proper proportions by hand and compare it (visually or better yet with a Penn State Particle Size Separator) to what is coming out of the mixer wagon.

Don’t feed to an empty bunk—————–

The feed that is swept out should look like the feed that was put in. A bunk with only corn cobs and long, fibrous particles is an empty bunk! Feeding to an empty bunk will result in slug feeding and acidosis.

Maintain adequate feed bunk space and push feed up often———————

At least 18-24 inches (46-61 cm) of feed bunk space per cow is recommended. The ration should be pushed up to the cows often (at least 6-8 times per day), especially if bunk space is marginal.

Timing of Feeding——————–

Feed when cows want fresh feed (i.e. after milking). Many farmers only feed their TMR once per day. With adequate feed access (plenty of push ups) this strategy can work O.K. Most nutritionists, however, would agree that more feedings per day encourages cows to eat.

Watch Out For Sorting——————————

Cows will take their noses and wiggle down through a TMR to sort out the grain from the forage. This process provides the rumen microbes with a few mainly grain meals and a few mainly forage meals per day, just like component feeding without a TMR. The result is acidosis. Ration dry matter can dramatically affect the incidence of sorting. The drier the ration, the more sorting. Sorting has been reduced when water was added to rations containing more than 50% dry matter to bring ration dry matter down to 43%. Also, if the ration is too coarse (especially with coarse-cut dry corn silage), cows will sort. Feeding cows more frequently will also help reduce problems with sorting.

REFERENCE-ON REQUEST