CURRENT STATUS AND OUTLOOK IN EGG PODUCTION OF CHINA

China has been the world’s largest egg producing country since 1985 and accounted for 34.1% of the global egg production in 2019, according to the latest data from the Food and Agriculture Organization of the United Nations.

This represented production of 28.4 million metric tons is more than four times that of the USA. China’s massive egg output been achieved through the hard work of countless small egg producers.

China produces more than 40% of eggs worldwide and is continuing to increase its egg production. The Chinese government is encouraging its egg industry, to help secure China’s access to safe and nutritious food. In the 1980s farms were state-run but now they are privately owned and China is now almost self-sufficient in egg production, meeting the need for egg consumption in its population of 1.4 billion people.

Changes in egg supply and demand

Eggs contribute approximately 6% of protein in the diets of Chinese people. In rural areas, consumption of eggs is lower than in urban areas (5.9 kg eggs/head compared to 10.5 kg eggs/ head in 2012). It is expected that the demand will continue to increase as urbanisation increases. In 2016, 31 million tonnes of eggs were produced.

Highlights

- China is now the largest egg production country worldwide

- Egg production in China is characterized by diversity in several aspects

- China is now capable of breeding new varieties, with more than 50% of the market share

- Policies have been implemented to ensure sustainable development of egg production

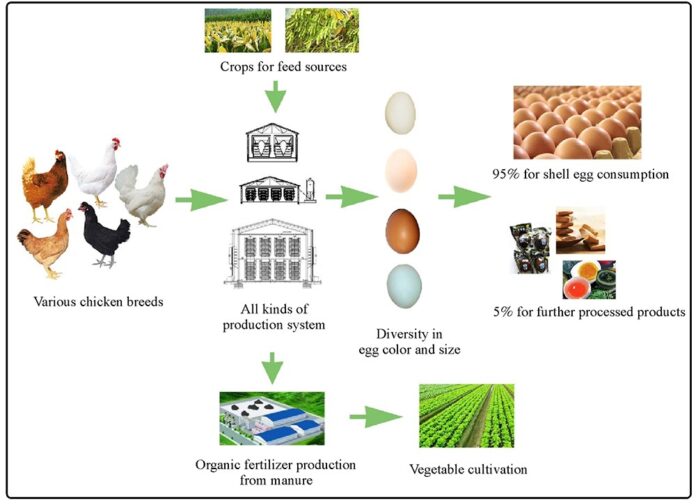

- Integrating crop-chicken-vegetable production system is established

Abstract

Eggs are one of the most nutritious and affordable animal products worldwide. From 1985, egg production in China has retained the leading place in the world. A total of 33 Mt of eggs were produced in 2019 representing ˃ 40% of the world total production. Egg production in China is characterized by diversity in several aspects, including layer breeds, products and production systems. New breeds and synthetic lines are developed to improve the genetic potentials of egg production and feed efficiency of layers. In the past, layer farms were run mostly by small households with 100 to 1000 layers per farm. Over the past decades, egg production in China has developed toward standardization and expansion of production systems, and many of these modern intensive farms raise millions of layers. Although the Chinese egg products maintain strong competitiveness over other animal products and imported egg products, the egg industry will grow at a slower pace compared to the past. Chinese consumers are more concerned about the quality and safety of eggs and egg products, as well as the environmental issues related to animal production, which presents challenges for the Chinese egg industry.

1 INTRODUCTION

Eggs are among the most nutritious foods on the planet. A whole egg contains all the nutrients required to develop an embryo into a healthy baby chick. In fact, eggs are considered the perfect food and provide almost every nutrient important for human health, such as protein, healthy fats, vitamins, folate, phosphorus, selenium, calcium, zinc and other minerals. Due to the presence of docosahexaenoic acid, eicosapentaenoic acid and immunoglobulin, eggs are beneficial for human health, especially for pregnant women and infants[1].

As the world population grows steadily, egg production worldwide has become one of the most important agricultural sectors and an essential part of the global food supply. Their relative cheapness and abundance make eggs an important animal protein source for people in poorer countries, together with fish. In wealthier parts of the world, eggs constitute a healthy component of the diet. Worldwide demand for egg production is still growing rapidly[2]. Egg consumption has risen by around 40% over the past 20 years.

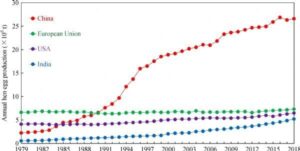

China has a long history, more than 5000 years, of poultry production and has experienced four stages of development in egg production[3], including the natural growth stage (before 1978), the initial period of fast development (1979–1990), the explosive development period (1991–2000) and a steady stage (since 2001). The implementation of the Reform and Opening-up Policy since 1978[4] is the key factor boosting Chinese egg production in every aspect including capital investment, technology advancement, business model and purchasing power. In 1985 China surpassed the USA to lead the world in egg production. Since then China has had an increasingly important role in world egg production. Nowadays, China produces and consumes more than 40% of global egg production and the total egg production was 33 Mt in 2019, a 12-fold increase from 1978 (Fig. 1)[5]. Food demand is actually the main driving force for the increase in egg production. China is a country with a large population and the demands for food are enormous. Average egg consumption per capita is now around 18 kg per year in China, which is more than the average level in developed countries. Hence, over the past 40 years China has had a much faster growth pattern of egg production than that in the USA or European countries. The government has played active roles in this process mainly in two aspects: one is to encourage the establishment of standard layer farms and the other is to promote elite breeding chickens with high performance. Along with the increase in egg production, environmental regulations are more stringent. Many policies have been carried out to control pollution from layer production, organic fertilizer production from chicken manure, and the disposal of sick and dead laying hens.

Fig.1 Egg production over the past 40 years in China and other important regions (data from FAO website[5]). |

China also has a great diversity of eggs from various avian species. While the rest of the world relies on chicken layers to produce table eggs, eggs from duck, quail and goose are also popular in Chinese markets due to the production tradition and the need for food diversity. Chicken, however, has been more efficient in producing table eggs and the relevant production system is more advanced. Thus, 85% of table eggs in China are produced by chicken layers.

This paper provides an overview of the current status of and challenges faced by egg production in China, allowing the development of a better strategy for future development. To be more specific, the focus is on chicken egg production.

2 CHARACTERISTICS OF EGG PRODUCTION IN CHINA

Due to the long history, rich tradition and large quantity of chicken production, China has developed unique characteristics for egg production. There is one word, diversity, which may help properly to understand Chinese egg production with regard to genetic variety, egg products and production system.

2.1 Genetic diversity

Genetic potential is fundamental to any agricultural system of animals or crops. The Chinese government and industry have placed great importance on genetic diversity in egg production. Basically, there are three ways to achieve this goal: genetic improvement of indigenous breeds, importation of commercial hybrid layers from other countries, and development of new domestic hybrids.

Benefiting from a vast land, geographical and ecological diversity, distinct living habits and long-term domestication tradition, China has 114 unique and various indigenous chicken breeds, such as the Silky, Dongxiang blue shell chicken and Tibetan chicken[6]. These breeds are adapted to different environments and produce various kinds of eggs, but generally have poorer performance in growth rate and egg production compared to commercial hybrids. These genetic resources provide abundant and indispensable breeding materials for genetic and genomic research. Also, scientists and breeders are actively working to improve these breeds and incorporate them in modern breeding programs for better performance and efficiency.

Commercial three- or four-way hybrid layers are used for the majority of egg production. When China opened up in the late 1970s, foreign commercial breeds started to predominate in the Chinese egg industry due to superior production performance. The breeding stocks have been imported mainly from the USA and Europe. At the beginning of the 21st century, nearly 90% of the layers kept in China were foreign breeds. Encouraged by the Chinese government and industry, scientists and breeders have been working together to explore the genetic basis of important traits, develop new genetic and genomic tools, and build sophisticated breeding programs with broader genetic resources. Over the past 20 years, 19 new genetic lines have been developed and approved by the Chinese National Commission of Animal Genetic Resources. These domestic breeds have shown distinct advantages over foreign layers in adaptation to Chinese production conditions, and have excelled in either egg production or feed efficiency. These domestic breeding stocks have been distributed extensively throughout the country and have replaced a large proportion of the foreign layers. At present more than 50% of the commercial layers are Chinese domestic breeds, which is substantial progress in the field of animal husbandry. The following are a few examples of the new domestic breeds.

2.1.1 Highly productive variety: Jing Pink-6

This layer meets the unique demands of the Chinese market for medium-sized pink eggs, and genomic selection has been applied in the breeding program which has enhanced the genetic progress in most economic traits. Jointly developed by Huadu Yukou Poultry and China Agricultural University (CAU) in 2019, this breed sets a new record in the national performance testing for egg number; 324 eggs at 72 weeks of age per hen. A distinct feature of the layer is its brown feathers which have led to the discovery of a new mutation in feather color genes.

2.1.2 Efficient dwarf layer: CAU-3

A shortage of domestic supply of feed grains, especially soybeans, encourages Chinese breeders to place more emphasis on feed use efficiency in animal production. It is necessary to develop new chicken breeds with a smaller body, lower feed consumption and constant egg numbers. By introducing a sex-linked dwarf gene, a line of brown-egg dwarf layers was developed at CAU[7]. Scientists and breeders then performed selective breeding and developed a new commercial variety, dwarf layer CAU-3. The adult bodyweight of dwarf layer CAU-3 is about 1500 g and the daily feed consumption about 90 g, 15% less than that of normal layers[8]. CAU-3 layers have good laying performance, 306 eggs per year per hen. Combining all these traits the feed conversion rate is less than 2:1, representing a significant advance in production efficiency.

2.1.3 Blue eggshell layers

Eggshells have different colors resulting from certain pigments. While white and brown are the two most common eggshell colors around the world, the blue eggshell has distinct attractions to customers in China. Yang’s group at CAU studied the genetic basis of the blue eggshell phenotype in Dongxiang chicken with both genetic and genomic approaches, and identified the solute carrier organic anion transporter family member 1B3 gene (SLCO1B3) as the functional gene responsible for the unique trait. An EVA-HP insertion was found that promotes the expression of SLCO1B3 genes in the shell gland of the oviduct causing blue eggshell in chickens[9]. This finding was used to develop a molecular diagnosis kit of the genotypes, which facilitates the breeding of two new commercial breeds, Xinyang Blue and Suqin Blue layers[10] which were approved by the China National Commission of Animal Genetic Resources in 2010 and 2013, respectively. These are good examples of using indigenous chicken breeds with the help of modern genetic and genomic tools.

2.2 Product diversity

It is estimated that 70% of eggs worldwide are consumed directly as fresh table eggs and 30% are processed into egg products. Egg products are used as ingredients for foods such as baked goods, pastries, meat and dairy products, and soups[2]. In China, the situation is quite different. Over 95% of eggs are sold as table eggs for direct consumption. Thus, the eggshell and egg size are two important attributes that customers consider in making purchases.

Although there is no solid scientific evidence that the eggshell color has a significant effect on the nutritional value of table eggs, customers in different countries will normally develop certain patterns of preference. While white eggs are predominant in the USA market, brown eggs are more accepted in Europe. Due to abundant genetic resources, one can easily find any type of egg in Chinese markets.

The Chinese market forms a more diversified structure than that of any other country. There are mainly four types of fresh eggs, namely brown (55%), pink (43%), white (1%) and blue shell (1%) eggs[11]. While the brown eggs form the majority of table eggs, pink eggs, sometimes called light brown eggs, have gained increasing popularity with Chinese consumers due to their similarity to the eggs from indigenous chicken breeds. Pink eggs are produced mainly by hybrids between brown-egg and white-egg layers. Comparing pink eggs, a smaller size (40–55 g) can gain a higher price due to the higher egg yolk ratio and better flavor.

Most commonly fresh eggs have been sold at open markets without packing or trademarks. The Chinese egg industry has recently been working to develop various ways of processing eggs. Eggs in household backyard farms are simply packaged after collection for distribution. Commercial companies, clean and grade table eggs and pack them in various boxes with their own brands. Automatic machines are widely used to collect, grade and package eggs. Advanced egg production corporations also produce various forms of processed products including Chinese traditional products such as century eggs and stew eggs, and further processed products such as liquid egg, frozen egg, egg powder and boiled egg. It is estimated that fewer than 5% of hen eggs (1.74 billion) are processed from the total egg production (350 billion eggs), and only about 8.2% of further processed products are pasteurized eggs[12].

The production of egg components from egg whites or yolk has also scaled up. Lysozyme and lecithin are egg active components, and the methods of extracting these two substances from eggs are relatively mature and therefore widely used in the food, medicine and chemical industries. Lysozyme plays an important role in nonspecific immunity for humans and has bactericidal and anti-inflammatory actions. It has been widely used in medicine, for example in the treatment of acute and chronic nasopharyngitis, dental ulcers, chickenpox and herpes zoster. The products include lysozyme mouthwash, oral spray, lysozyme toothpaste, and lysozyme enteric coated tablets. Yolk lecithin is claimed to delay aging, protect the stomach and liver, favor the use of fat-soluble vitamins and improve the efficiency of blood circulation, with good physiologic and drug functions.

2.3 Production diversity

Raising chickens and other poultry to produce eggs in China was not a business in general before 1978 but was a byproduct of rural life. As in many other countries around the world, backyard farming has been practiced for thousands of years. Over the past 40 years the egg industry in China has been shifting gradually from traditional backyard farming to layer farms of various sizes. Many different methods are used for keeping poultry. These production systems range from small, village-level poultry farms to modern integrated intensive operations in which large companies control all aspects of the production and marketing chain. One can find diversified production systems coexisting in most parts of the country, from hundreds of caged laying hens in simple shelters in the same yard where farmers live, to modern farms practicing industrial-type production with millions of layers. In 2010, the Chinese Ministry of Agriculture started a nationwide project to promote the standardization and expansion of layer farms, with substantial impacts on the production structure of the egg industry, and more details are given in the next section. As a result of the joint efforts of the industry, the market and the government, a number of large egg production corporations have developed recently, such as Beijing DQY, Beijing CP, Hubei Shengdan and Sichuan Shendile[12]. However, this transition needs large investment and significant improvements in management and technology. There is still a long way to go in modernizing egg production in China.

3 CURRENT STATUS OF THE EGG INDUSTRY IN CHINA

3.1 Geological distribution

Egg producers in China are mainly located in the northern and central regions of the country where most grain is produced and the climate is more suitable for chicken production. Table eggs are transported across the country along the rapidly developing highway network. In recent years, however, egg production has tended to spread nationwide in order to market fresh eggs locally and reduce transportation costs. At present, the top four egg-producing provinces are Hebei, Henan, Liaoning and Shandong, with a total egg output of more than 2.50 Mt in 2018. Anhui, Hubei, Jiangsu, Jilin and Sichuan provinces have a combined egg production of over 7.7 Mt[12]. The eggs produced in these nine leading regions account for 74% of the total national production (Table 1). It should be noted that the top egg production regions are also the top producers of corn, the main ingredient of poultry feed. Corn production in Heilongjiang, Jilin, Inner Mongolia, Shandong, Henan, Hebei, Liaoning and Sichuan was up to 191.1 Mt in 2018, accounting for 74.3% of the total amount (257.2 Mt). Egg marketing in China can be simply characterized as a flow from north and north-east China (Hebei, Shandong, Henan, Hubei, Liaoning, Jilin) to south-east and south China (Guangdong, Zhejiang, Fujian, Guangxi, Chongqing, Yunnan) and to large cities such as Beijing, Tianjin and Shanghai. Most of the other regions maintain a balance between supply and demand.

| Tab.1 Poultry egg production in each region of China in 2018 | ||||||

| Rank | Region | Poultry egg output (10,000 t) | Rank | Region | Poultry egg output (10,000 t) | |

| 1 | Shandong | 447.0 | 17 | Chongqing | 41.5 | |

| 2 | Henan | 413.6 | 18 | Guangdong | 39.2 | |

| 3 | Hebei | 378.0 | 19 | Xinjiang | 37.3 | |

| 4 | Liaoning | 297.2 | 20 | Yunnan | 32.7 | |

| 5 | Jiangsu | 178.0 | 21 | Zhejiang | 31.5 | |

| 6 | Hubei | 171.5 | 22 | Guangxi | 22.3 | |

| 7 | Anhui | 158.3 | 23 | Guizhou | 20.0 | |

| 8 | Sichuan | 148.8 | 24 | Tianjin | 19.4 | |

| 9 | Jilin | 117.1 | 25 | Ningxia | 14.4 | |

| 10 | Heilongjiang | 108.5 | 26 | Gansu | 14.1 | |

| 11 | Hunan | 105.4 | 27 | Beijing | 11.2 | |

| 12 | Shanxi | 102.6 | 28 | Hainan | 4.7 | |

| 13 | Shaanxi | 61.6 | 29 | Shanghai | 3.2 | |

| 14 | Inner Mongolia | 55.2 | 30 | Qinghai | 2.3 | |

| 15 | Jiangxi | 47.0 | 31 | Tibet | 0.5 | |

| 16 | Fujian | 44.3 | ||||

| Note: Data for Taiwan, Hong Kong, and Macao not shown[11]. |

3.2 Scale of layer farms

In 2013, Yang et al.[13] conducted a survey of egg production in the nine leading regions. Based on layer numbers the farms were classified into six categories: back yard (<2000 hens), small family farm (2000–4999 and 5000–9999 hens), specialized layer farm (10,000–49,999 and 50,000–100,000 hens) and large layer farm (>100,000 hens). Table 2 shows that small family farms were the predominant type (72.4%) reflecting the historical development of the Chinese egg industry where numerous farmers are involved in egg production but with limited capital investment, available land or management skills to expand layer numbers. Farms with 2000–4999 hens accounted for about half of the total. It was noted that farms with 10,000–50,000 hens had the greatest proportion (34.9%) of housed laying hens. Within the range of what many farmers can afford, small-scale farms are more stable and less sensitive to factors such as egg prices.

While the majority of layers are still kept in small to mid-sized farms, there has been an unprecedented development of large industrialized egg corporations over the past decade at the cost of small family farms. Since 2012 the number of layer farms has been decreasing and the average farm size increasing[13].

| Tab.2 Poultry farm scale and egg production in China | ||||||

| Scale (hens per farm) | Farms | Hens housed | Cumulative (%) | |||

| Number | % | Number | % | |||

| <2000 | 2814 | 14.9 | 3,590,500 | 3.5 | 3.5 | |

| 2000–4999 | 9386 | 49.6 | 28,075,000 | 27.4 | 31.0 | |

| 5000–9999 | 4311 | 22.8 | 26,530,000 | 25.9 | 56.9 | |

| 10,000–49,999 | 2285 | 12.1 | 35,711,000 | 34.9 | 91.8 | |

| 50,000–99,999 | 92 | 0.5 | 5,805,300 | 5.7 | 97.5 | |

| >100,000 | 21 | 0.1 | 2,570,000 | 2.5 | 100.0 | |

| Total | 18,909 | 100.0 | 102,282,000 | 100.0 | ||

| Note: Data adapted from Yang et al.[13]. |

Farms of any scale use similar feed ingredients, namely corn, soybean meal, vitamins, trace minerals, amino acids, phosphorus, oils and stone powder. Small farms with limited labor tend to buy complete feed while if extra labor exists, they tend to buy premixed ingredients to produce complete feed manually. At a scale of 20,000 to 50,000 most farms have automation equipment, hence most use premixed ingredients to produce complete feed. Farms with 50,000–150,000 chickens have the power to negotiate price and quality, hence most buy complete feed. Larger farms are part of integrated enterprises that can supply complete feed from their own feed mills.

3.3 Housing system

There are three main chicken housing systems in China, namely open, semi-open and closed layer houses. Open or semi-open layer houses are used widely on family layer farms. Open houses are sheltered with a roof only while semi-open houses are surrounded by four walls with windows on the south and north walls. Open houses are no longer used due to biosecurity and environmental considerations, while semi-open house remain popular in rural areas. As modern intensive farming increases, closed houses without windows have been widely constructed with artificial lighting, cooling pads and ducted mechanical ventilation.

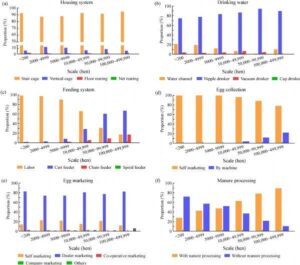

Compared to floor rearing the cage system has been widely adopted by the Chinese egg industry for more than 30 years due to greater management and sanitation control, higher utilization of available space and lower labor requirement (Fig. 2(a)). Stair cages are a major housing system on most farms (>85%). The use of vertical cages with manure belt has increased recently for automatic collection of manure and higher stocking density. In this system the manure is dried on ventilated belts and then removed to the outside for further processing. The NH3 emission factor for vertical cages is much lower than that for stair cages[14] and vertical stages with manure belt are important in reducing the environmental impact. Currently, furnished cages have been advocated and adopted in many countries, especially in the European Union and the United States. Animal welfare is generally given lower priority in China but there has been some pioneering research exploring the implementation of new welfare systems for egg production.

3.4 Management facilities

Management in layer houses involves providing drinking water, feeding systems and egg collection (Fig. 2(b–d)). According to a survey[13], nipple drinkers are the main means of supplying clean water. More nipple drinkers are used in large layer farms and 18% of small farms still use outdated water channels with associated risk of water contamination. Feed is mainly supplied manually, especially on small farms. In contrast, more cart feeders are used in larger farms with better uniformity and efficiency in allocating feed to layers. On small farms, eggs are collected by hand. On large farms, automatic egg collection systems are used to save labor and increase management efficiency at the cost of more egg damage. Using these automatic systems two laborers are adequate for the efficient management of 50,000 layers in one house.

Marketing by dealers is the major mode of egg sales for layer farmers. Concurrently, egg packaging and branding are rapidly developing and many large egg producers are promoting their own brands with efficient distribution networks. E-commerce platforms are widely used to market branded and diversified table eggs.

3.5 Manure treatment and application

3.5.1 Manure collection

Chicken manure contains high concentrations of macronutrients such as nitrogen, phosphorus, and potassium, which are essential for plant growth. Chicken manure has positive effects in enhancing soil fertility[15] and can be used in anaerobic digestors to produce biogas and organic fertilizer[16,17]. Hence, chicken manure is an essential part of an integrated system of animal and crop production. With the cage systems, chicken manure is much easier to collect on a daily basis. In addition, chicken manure dried on a belt with low humidity is less polluting to the environment and is convenient and cheap to transport and process.

3.5.2 Manure processing

The most common form of manure processing is composting and fermentation to produce organic fertilizer. More manure processing is performed on large farms (Fig. 2(f)). Beijing Deqingyuan Agricultural Technology Co., Ltd., has constructed the largest biogas power plant in the egg industry and has been using chicken manure as the main ingredient to undertake biogas power generation.

Fig.2 Management status in farms on different scales. The management in layer farms comprises a housing system (a), drinking water (b), feeding system (c), egg collection (d), egg marketing (e), and manure processing (f). Adapted from Yang et al.[13]. |

3.5.3 Application of chicken manure

The fertilizers produced from chicken manure are preferred in the production of fruit and vegetables across the country[18]. In farms of any scale the utilization efficiency of manure can be very high. Small farms sell or give chicken manure to a fertilizer factory. In the case of medium- and large-scale farms the manures are generally processed on-site by vertical fermentation cylinder at first, then the semi-finished products are used for organic fertilizer production in their own factories or sold to other fertilizer factories. The application of chicken manure fertilizers in apple, tomato and potato production can increase the quality and quantity of these products[19]. Many examples can be found in Guangdong, Shaanxi and Shandong provinces with successful practical use of chicken manure to increase productivity. Fertilizers derived from chicken manure are less commonly used in crop production due to price and fertilizer regimes used.

3.5.4 Control of odor discharge

There are rules in China for the discharge of odor such as the ‘Discharge Standard for Odor Pollutants’. The farm deodorization measures are as follows: (1) choose a reasonable site and try to avoid sensitive areas such as villages and schools; (2) pay attention to daily cleaning and sanitation of manure; (3) use a deodorization net and spraying system for deodorization if there are sensitive sites such as villages around farms; (4) decease pathogen risks mainly through enhanced fermentation treatment before manure utilization.

3.5.5 Integrating crop-chicken-vegetable production

The north-east plain and north China plain are the main crop growing areas in China, and layer feed is mainly based on corn and soybean meal. Correspondingly, the north-east and north China plain are also the main chicken raising areas. About 40%–70% of nutrients in the feed are excreted in the manure of laying hens. The manure yield is about 1.1–1.2 times the feed intake because 70%–80% of the manure is water. The contents of organic matter, nitrogen, phosphorus and potassium in chicken manure are 25.5%, 1.63%, 1.54% and 0.85%, respectively[20]. That is, a laying hen produces about 45.6 kg of manure in one year containing 0.74 kg of nitrogen and 0.70 kg of phosphorus. The manures are mostly used to produce organic fertilizers which are preferred to increase the yields of fruit and vegetables across China. This therefore forms an integrated crop-livestock-vegetable production system, recycling the nutrients nitrogen and phosphorus among crops, chickens and vegetables/fruit (see graphical abstract).

4 OUTLOOK OF THE CHINESE EGG INDUSTRY

4.1 Competitiveness of the egg industry

Eggs have been an essential and affordable ingredient of daily diets for Chinese consumers during the efficient development of the egg industry. Eggs are now the second largest dietary contributor of animal proteins after pork, due to their large quantity, high quality and affordable price. Laying chickens have demonstrated strong competitiveness with superior genetic potential and advanced technology in every aspect of the food supply chain. It is estimated that the protein from eggs costs only 71 CNY·kg−1, much cheaper than proteins from pork, beef, lamb and chicken meat.

Globally, the Chinese egg industry can also maintain relative competitiveness. China is the top egg producer globally and can produce eggs at a low average cost despite a higher feed price than in some other large countries such as the United States. Consumer demand for fresh table eggs has greatly limited the international egg trade. Imports of eggs and egg products by China have therefore always been negligible. Egg exports are also low, about 0.25% of the total production. Eggs are exported in processed products mainly as salted eggs to Hong Kong of China, the US and Canada. Egg powders used by the food processing industry are shipped to Japan and some other countries. Although the export of egg products grows slowly, there is great potential for further development with new products and business models.

4.2 Future trends and challenges

Standardizing and modernizing the egg industry has been widely accepted as a key trend in China. A strategy focusing on upgrading family farms and promoting large-scale automated farms has been suggested and implemented as a direction for future development. The Chinese Ministry of Agriculture and Rural Affairs has provided government guidelines and related policy to advance the ambitious transition. It is anticipated that the process of standardizing the egg industry will be challenged by the current diversified industrial structure, biosecurity, waste treatment, food safety issues and over-production in some years. Government and industry are working together to overcome these challenges. For example, the State Council has issued a Regulation on Pollution Prevention of Large-scale Livestock Production which promotes the efficient utilization of layer manures as organic fertilizers or biogas. To control the outbreaks of major infectious diseases an ‘Emergency Plan for Major Animal Epidemics’ and ‘Regulations on the Control of Animal Epidemic Situation’ have also issued been by the central government. The egg industry has implemented stricter rules to control the entire production chain to address food safety concerns of consumers. Branding of eggs is also used widely to ensure the traceability of fresh eggs and egg products by commercial companies and corporate farmers. Ultimately, multidisciplinary research on improving the quality and sustainability of egg production enhance the overall competitiveness of the Chinese egg industry.

References

Publishing order | Descend order by publishing year | Descend order by cited within

| [1] | Zaheer K. An updated review on chicken eggs: production, consumption, management aspects and nutritional benefits to human health. Food and Nutrition Sciences, 2015, 6(13): 1208–1220 |

| [2] | Yang N. Social economic aspects of egg production in China. In: Improving the safety and quality of eggs and egg products: Egg chemistry, production and consumption. UK: Woodhead Publishing, 2011, 17–26 |

| [3] | Simons P. Egg signals: a practical to improving egg quality. The Netherlands: Rood Bont Publishers B.V., 2017 |

| [4] | Garnaut R, Song L G, Fang C. China’s 40 Years of Reform and Development: 1978–2018. Acton ACT, Australia: ANU Press, 2018 |

| [5] | Food and Agriculture Organization of the United Nations (FAO). FAOSTAT: Livestock Primary. Data available at FAO website on September 2, 2020 |

| [6] | China National Commission of Animal Genetic Resources. Animal Genetic Resurces in China—Poultry. China Agricultural Press, 2011 (in Chinese) |

| [7] | Yang N, Ning Z, Wang Q, Li J, Wu C. Application of the sex-linked dwarf gene to improving feed efficiency of layers. In: Proceedings of the 20th World’s Poultry Congress, New Delhi, India. 1996, 447–451 |

| [8] | Ning Z H, Wu C X, Yang N, Zhang Q C. Breeding of grain-saving small laying hens–Nongda No.3 Layer. Journal of Agricultural Biotechnology, 2013, 21(6): 753–756 (in Chinese) |

| [9] | Wang Z, Qu L, Yao J, Yang X, Li G, Zhang Y, Li J, Wang X, Bai J, Xu G, Deng X, Yang N, Wu C. An EAV-HP insertion in 5′ flanking region of SLCO1B3 causes blue eggshell in the chicken. PLOS Genetics, 2013, 9(1): e1003183 |

| [10] | Wang K H, Zhou J M, Yang N, Ding Y R, Dou T C, Su Y J, Qu L, Bu Z, Tang Q P, Tong H B. Study on breeding of Suqin blue eggshell. China Poultry, 2014, 36(3): 43–45 (in Chinese) |

| [11] | National Bureau of Statistics of China. China Statistical Yearbook–2019. Available at the web site of National Bureau of Statistics of China, on May 1, 2019 |

| [12] | Yang Z, Rose S P, Yang H M, Pirgozliev V R, Wang Z Y. Egg production in China. World’s Poultry Science Journal, 2018, 74(3): 417–426 |

| [13] | Yang N, Qin F, Xu G Y, Zhao Y F, Xue L, Zhou X Y. Survey on the current development of layer farming in China. China Poultry, 2014, 36(7): 2–9 (in Chinese) |

| [14] | Fabbri C, Valli L, Guarino M, Costa A, Mazzotta V. Ammonia, methane, nitrous oxide and particulate matter emissions from two different buildings for laying hens. Biosystems Engineering, 2007, 97(4): 441–455 |

| [15] | Dikinya O, Mufwanzala N. Chicken manure-enhanced soil fertility and productivity: effects of application rates. Journal of Soil Science and Environmental Management, 2010, 1(3): 46–54 |

| [16] | Nie H, Jacobi H F, Strach K, Xu C, Zhou H, Liebetrau J. Mono-fermentation of chicken manure: ammonia inhibition and recirculation of the digestate. Bioresource Technology, 2015, 178: 238–246 |

| [17] | Li Y, Zhang R, He Y, Zhang C, Liu X, Chen C, Liu G. Anaerobic co-digestion of chicken manure and corn stover in batch and continuously stirred tank reactor (CSTR). Bioresource Technology, 2014, 156: 342–347 |

| [18] | Huang L, Yao L, He Z, Zhou C, Li G, Yang B, Deng X. Roxarsone and its metabolites in chicken manure significantly enhance the uptake of As species by vegetables. Chemosphere, 2014, 100: 57–62 |

| [19] | Isuwan A. Agronomic traits and fruit quality of pineapple with different levels of chicken manure application. Science. Engineering and Health Studies, 2014, 8(1): 67–73 |

| [20] | Parker M B, Perkins H F, Fuller H L. Nitrogen, phosphorus and potassium content of poultry manure and some factors influencing its composition. Poultry Science, 1959, 38(5): 1154–1158 |

Which are Asia’s largest egg producers?

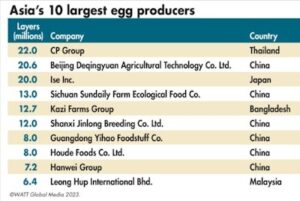

China may be the world’s largest egg producer, and its companies dominate a ranking of the region’s largest egg producers. But Chinese companies are yet to conquer all the top spots.

Latest figures from egg producers in Asia show that Thailand’s CP Foods continues to hold pole position, but five of the top 10 positions are now held by Chinese companies.

Asia accounts for over 64% of global egg production, with China being the world’s largest egg producer. Little wonder, perhaps, that a ranking of Asia’s leading egg producing companies is dominated by Chinese concerns, but it is not a Chinese company that leads our ranking of Asia’s 10 largest egg producers.

The top slot goes to Thailand’s CP Group, but it may not hold that position for long. Ranking number two in our table is China’s Beijing Deqingyuan Agricultural Technology Company Co. Ltd. The comp

TRENDS OF EGG PRODUCTION IN CHINA

Author

Ning YANG

Ning YANG. EGG PRODUCTION IN CHINA: CURRENT STATUS AND OUTLOOK. Front. Agr. Sci. Eng., 2021, 8(1): 25‒34 https://doi.org/10.15302/J-FASE-2020363

Acknowledgements

The survey reported in this paper was supported in part by the China Agricultural Research System on Layers (CARS-40). The author would like to thank the members of CARS-40 for their contribution and helpful discussion, and Dr. Congjiao Sun, Ms. Xiqiong Wang and Ms. Yuhui Qin (College of Animal Science and Technology, China Agricultural University) for their help in preparing this manuscript.

Source-https://journal.hep.com.cn/fase/EN/10.15302/J-FASE-2020363