Digital Dairy Technology

Priya Chouksey, Dr. N. K. Singh, Dr. Dhananjai Singh, Amrita Tiwari, Dr. K. K. Deshmukh, Dr. K. P. S. Saini- JNKVV, KVK Seoni

Dr. Ajay Rai, College of Veterinary Science and Animal Husbandry, NDVSU, Jabalpur

Since the days of the white revolution dairy farming has evolved as a profitable sector. To make Dairy farming more advance and to attract new generation towards dairy farming it is needed to modernize it in digital system, to gain more and more profit.

There are some digital ways to improve Indian dairy system:

Fitness tracker for cattle

![]()

Today, farmers may track, monitor, and control nutrition, behavior, pregnancy, milking frequency, milk output anomaly, and activity level in real-time owing to wearable animal gadgets which is very similar to human fitness trackers. Fitness tracker can tied on the neck of cattle which track eating, drinking behavior and movement of animal. If any issue found farmer can get alert in the mobile and immediately book the veterinary service just by clicking button in his mobile. These intelligent animal trackers may also be placed in ears, tails, legs, neck, or any other portion of the cattle body.

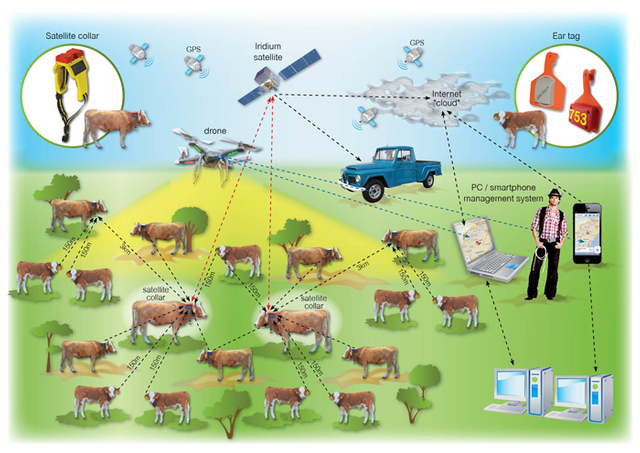

Drones for Cattle Monitoring

Cattle spend extended times out in the fields, pastures, hills, it is time-consuming and labour-intensive to monitor the whereabouts of herds and flocks.

Traditional tracking methods rely on human observations either by identifying them by natural features such as colouring and breed, or by marking and identifying individual animals by artificial means such as coloured collars, tags or painted-on symbols. This has potential for observer error and fatigue.

A drone used for surveillance purposes, equipped with a camera alone, is sufficient to add an autonomous, remote method for farmers and shepherds to track the whereabouts of livestock to keep an eye on the stock from the kitchen table of the farmhouse.

But that power increases significantly with the addition of other technology such as sensors, GPS location information and animal identification systems. That can be overcome by drones as drones may also scan pasture lands and communicate information about whether they are suitable for cattle grazing.

Milking via robots

It is a time consuming job that cows have traditionally been milked manually. Robotic milking allow farmers to minimize the need for physical labor, maintain a sanitary milking procedure, milk cows at any time of day rather than on a set schedule and increase milk output.

Automatic milking places emphasis on the cow’s motivation to visit the AM system to be milked voluntarily. Cows can more or less decide themselves when to visit the AM system. The main underlying motive for a cow to visit the AM system is the supply of concentrate; therefore, all AM systems are equipped with concentrate dispensers. In the transition from conventional to automatic milking, cows have to learn to visit the AM system at other times than before. This needs special attention, and in the first days or week, human assistance will be necessary. Especially heifers with no history of conventional milking adapt themselves very easily to the conditions of automatic milking.

The robotic milking equipment has arms or cups with sensors that may be fitted to the teats of cows individually. The sensors can detect whether or not the cow or one of its teats is ready for milking. Once the milking process begins, the devices can detect contaminants, color, and milk quality. If the milk cannot be consumed by humans, it is directed to a different container. When the process is completed, the devices may also clean and disinfect the teats automatically.

Customer Product Traceability

Product traceability is the ability to identify, track and trace elements of a product as it moves along the supply chain from raw goods to finished products. It provides numerous benefits such as the ability to investigate and troubleshoot issues related to a component or ingredient.

Customers nowadays want to know where their dairy products come from, from farm to table. This necessitates end-to-end supply chain transparency to increase client confidence. An increasing number of dairy producers, suppliers, and other stakeholders are utilizing block-chain technology to provide customers with real-time data about their products.

This is accomplished by including a QR code on the packaging that customers can scan with their mobile devices to obtain information about the origin of the milk – where and how it was obtained and packed, how old it is, what type of transportation and cold milk chain facilities were used, and so on.