Housing Requirements for Different Categories of Pigs

Shivani Singh, Argana A K, Dr. Anuj Chauhan, Dr. Mukesh Singh and Dr. Gyanendra Kumar Gaur

Livestock production management division ,Indian Veterinary Research Institute, Izatnagar,Bareily.

Introduction

The swine population in India is projected to be 9.06 million, contributing for 1.69 percent of the country’s total livestock population of 535.78 million. Indian pigs account for around 1% of the global pig population (DAHDF,2019). Since the last census, the number of pigs has declined by 12.03 percent. Rural areas are home to around 89.62 percent of all pigs. The year 2019 (DAHDF). Several Northeastern states have shown growing or stable trends. Assam, Jharkhand, and Meghalaya have the highest growth rates of 28.3 percent, 32.69 percent, and 29.99 percent, respectively, while Uttar Pradesh and Bihar have the lowest. According to data, swine production accounts for 4.98 percent of overall meat output in India, with approximately 10.7 million pigs slaughtered in the preceding fiscal year. (APEDA three-year export statement, 2020; Basic Animal Husbandry & Fisheries Statistics, 2019).

The entire amount of meat produced in India in the fiscal year 2019 was approximately 1000 metric tonnes. Pigs make for 4.98 percent of total meat production in India. Approximately 10.7 million pigs were slaughtered in the preceding fiscal year. (APEDA three-year export statement, 2020; Basic Animal Husbandry & Fisheries Statistics, 2019).

Pig farming has become a profitable business due to advantageous economic characteristics such as being very prolific, having a higher growth rate, having a shorter generation interval, having a low cost of rearing, and having a high dressing percentage with greater feed conversion efficiency (Prasad et al. 2011). Pigs can be raised in three ways: extensively/free range, semi-intensively, or intensively. In India, pig farming and the pork industry are shifting from a traditional to an intensive system. Asian countries have grown intensive pig farming at a quicker rate than the rest of the world (Cameron 2000).

Because of the growing human population and urbanisation, the majority of pig farmers, particularly those in peri–urban areas, are concerned about maximising available space for suitable pig housing. Housing is expensive at first, especially with the recommended larger area allotment, which can discourage farmers from starting pig farming. Higher pig space recommendations based on outdated housing standards are predicted to have an impact on the Indian pork industry’s economic competitiveness. From three weeks on, the appropriate balance between the number of pigs in the group and the available area is critical to the proper rearing of pigs (Bhat et al. 2010).

Efficient use of pen space without compromising pig productivity or well-being is critical for pork production (Anil et al. 2007). In India, very few research on space allowance in pigs have been conducted, and those that have been conducted have either used varied group sizes/pens or have been limited to a specific growth stage (Sinha et al. 1990, Sharma et al. 2004). Sharma et al. (2004) determined that 0.9 m2/pig allowance outperformed 1.2 m2/pig allowance, indicating that additional floor space allowance is not desired.

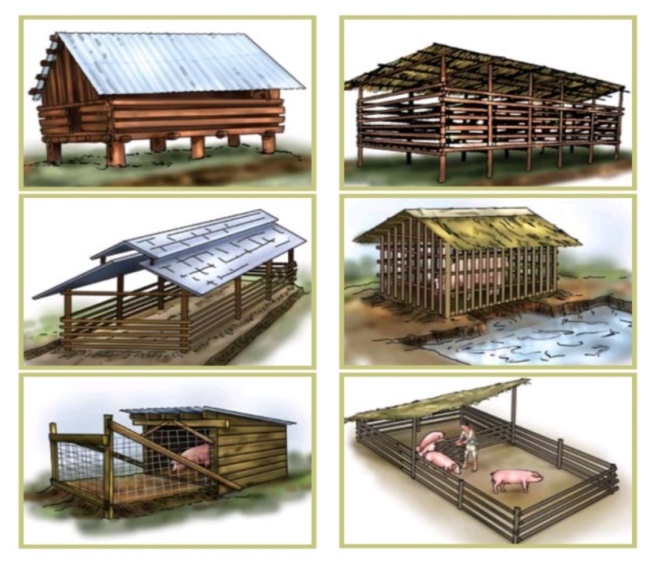

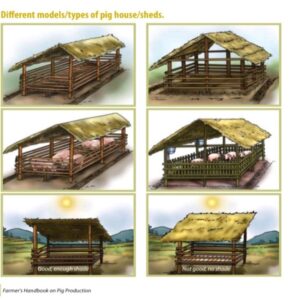

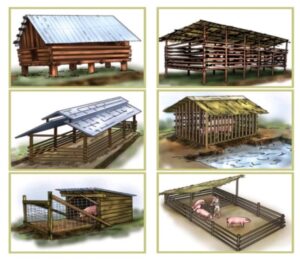

Design of Pig housing

|

|

Pig houses should be made to ensure optimum comfort for greater growth, as well as to avoid dampness in the buildings. Pig housing is dependent on a farming system that varies according to the prevalent conditions in that area, as well as the financial situation of the farmers. The housing system should be designed to put as little strain on the land as possible, and it might be intensive, semi-intensive, or extensive. The layout and style of pig housing vary due to varying soil and climatic conditions.

Location of pig houses

Structures should be built on a reasonably high and well-drained site that is not prone to floods, and the land should not be clayey. Structures should be at least 15 metres away from households, 30 metres away from dairies, animal and poultry houses, 45 metres away from fire sources, and one kilometre away from slaughterhouses and tanneries. The site’s boundaries must be 50 metres away from the roads. A sufficient quantity of water should be provided at the location.

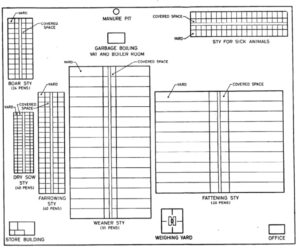

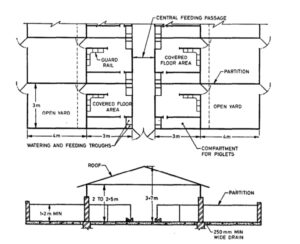

Fig : Layout of a pig farm (BIS, 1966)

Table1. BIS space requirements

| SNo. | Type of animal | Covered floor area(m2) | Open yard area(m2) |

| 1 | Boar | 6.25 to 7.5 | 8.8 to 12 |

| 2 | Farrowing sow | 7.5 to 9 | 8.8 to 12 |

| 3 | Weaner /fattening pig | 0.96 to 1.80 | 8.8 to 12 |

| 4 | Dry sow or gilt | 1.80 to 2.70 | 1.4 to 1.8 |

Table.2 Feeding and watering trough area requirement

| SNo. | Type of animal | Length (cm) |

| 1 | Boar | 60 to 75 |

| 2 | Sow and litter | 75 to 100 |

| 3 | Fattening pig | 30 to 40 |

| 4 | Weaner | 20 to 30 |

The amount of water for boar, farrowing sow, fattening sow and dry sow will be about 40 to 50l, 18- 20 l, 3.5 to 4l, and 4-5 l respectively.

Houses for different categories of pig

Pigs are housed in Sties, which are separated into one or more pens, with each pen containing a single or group of animals based on age, sex, and purpose. The size of the pens is determined by the number of animals to be kept and the floor area provided per animal. Different sorts of Sties are available for different categories of pigs in big scale commercial piggeries for easier control.

Boar sty:

Protection of boars from temperature extremes is critical, since high temperatures can quickly lead to decreased sperm fertility and libido. Strongly built boar accommodation is needed, especially to prevent boars from escaping and fighting. Wire reinforcements can be utilised for walls, however door bolts and hinges must be of high quality. Each boar sty shall not contain more than 24 pens under one roof, with no more than one animal per pen. The floor area of a boar pen should be 7m2, but if the pen is to be utilised for servicing, the minimum floor space need is 9m2.

Dry sow / gilt sty:

Each sty should not have more than 40 pens under one roof, and each pen should be able to house two, five, or ten animals depending on the stage of pregnancy. For about a month after weaning her litter and for around two weeks before farrowing. Dry sow housing and feeding management are in a vital period. Dry sows should be kept in containers, groups, or tethers.

Farrowing / nursing sow sty:

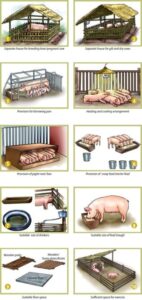

Fig: farrowing sty

Each farrowing sty usually has no more than 40 pens, with each pen housing one sow and her litter. The farrowing sty should be built with enough space for the nursing sow to sleep and the piglets to move around. Along with the walls, piglet compartments in one or two rows must be provided. Each compartment must be 2m high. Each compartment facing the nursing sow must have a 300225mm opening. Each compartment must have a watering and feeding trough. Guard rails shall be provided 25cm above the floor level.

Fattening sty:

Each fattening sty typically has no more than 20 pens, with each pen housing 16-32 fattening animals.

Sty for weaner piglets:

Each sty should contain no more than 30 pens, with each pen housing 10-20 animals ranging in age from 2 to 6 months.

Sty for sick animals:

A minimum of 5% of the stock must be set aside for sick animals, and the sty must be located at a suitable distance from the other locations to ensure adequate separation from healthy animals.

Farrowing crate:

It is constructed using steel pipes or round steel rods. The container should be designed such that there is adequate open space behind her for easy farrowing and to keep the piglets from being overwritten. Ample walking space should be provided for the piglets behind the sow. The container should be 400 mm above the floor, 450 – 500 mm wide, and 2500 mm long.

Creep area:

For the piglets, a 600mm by 600mm creeping pen with bedding must be given. For bedding, wood shavings are ideal. In a creeping pen, the ideal temperature ranges from 27°C to 32°C. Temperature variations of more than 5 degrees Celsius must be avoided in the creep area. Infrared lamps can be used to keep the temperature stable.

Constructional details of sties

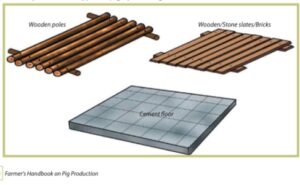

Floor

The floor should be sturdy and heated, water resistant, and simple to clean. Cement concrete floors can be laid or paved with cement concrete flooring tiles, stone slabs, or bricks set in cement mortar or lime mortar. Joints between stone slabs or bricks should be filled with binding material. The floor should slope away from the drain. The height of the walls from the floor must be between 2-2.5 m. Up to two-thirds of the height of the wall can be built of bricks with cement mortar or lime mortar, and the remaining half of the wall can be made of a succession of wooden rafters, each rafter measuring at least 2540 mm. The distance between two rafter should not exceed 350 mm

Fig: Types of floor in swine housing

Roof

The roof could be RCC flat or gabled. Roof materials for gabled roofs may include asbestos, cement sheets or clay sheets, corrugated galvanised steel sheets, or clay tiles. In the event of extreme weather, the roof can be insulated by adding a layer of thatching or a ceiling to lessen the severity of heat inside the sty.

Doors

The number of doors in each sty is determined by its proportions. The doors must be robust and fitted so that they are near to the floor level. The doors must be robust and fitted so that they are near to the floor level. The door leaves might be constructed of wood or galvanised steel sheets. Angle irons could be used to make the door frame. Individual pen doors can have a width of 1.2 to 1.5 m and a height of 1.2 to 2 m.

Ventilators

Ventilators must be installed if the sites are closed on all sides. The number of ventilators necessary is determined by the size of the sty. Each ventilator must be 0.6 m tall and 1 m long. The ventilator’s top must be 0.5 m above the highest point of the wall. Wire netting must be used to cover each ventilator from the outside.

Drainage

For proper drainage, each sty must have at least one drain on one side. The drain must be at least 250 mm wide and slope 25 mm every 10 m.

Subsidiary items

Weighing yard: The specifications for the weighing yard may differ from one location to the next. A weighing shed shall be provided, with a weighing scale installed to record the weights of the animals on a regular basis.

Store building: A store building may include a storekeeper’s office, a mixing room for mixing animal feed, a room for storing miscellaneous items such as farm equipment and tools, and a feed store for bulk storage of feed in bags.

Loading and unloading ramp: The farm shall have a permanent loading and unloading ramp.

Manure pit: The manure pit shall be built at a distance of not less than 15 metres from the farthest end of the sites and shall be built in such a way that the manure can be used for agriculture purposes.

Wallowing tank:

It may be available in pig breeding farms located in hot zones. The wallowing tank must be composed of cement concrete and have dimensions of at least 2.51.20.15 m. During the summer, overhead sprinklers or showers may be installed to keep the animals cool.

HOUSING AND STOCKING DENSITY OF PIGS

Overstocking is done on purpose in some pig farms; however, higher stocking density should be used only in very properly managed finishing units (Bhat et al. 2010). While developing floor area recommendations for pigs, environmental enrichment strategies that take into account natural pig behaviour should be prioritised. When group sizes of 6, 18, and 36 were maintained at a constant floor space limit, group size had no effect on feed intake, but bigger groups had lower feed conversion efficiency (FCE) (Petherick et al. 1989).

High stocking density has been shown to reduce the FCR of finishing pigs (leek et al. 2004). FCE is superior in terms of space (1.4 m2/pig) than finisher pigs (1 m2/pig) up to 160 kg body weight (Rossi et al. 2008). Pigs that were crowded (0.52 m2/pig) exhibited worse feed efficiency (2.7 versus 2.5 lb feed/lb gain, respectively) than pigs that were not crowded (0.78 m2/pig), ADG was higher in the un-crowded pigs, and feeding time was shorter in the crowded pigs, with no difference between the two groups (street and Gonyou 2008). Crowding has a negative influence on growth mostly because it reduces feed intake. When growing-finishing pigs are provided less than optimal room per pig, feed intake always declines (Brumm et al. 2001), frequently resulting in a decrease in ADG with varying effects on the G:F ratio (Cho and Kim 2011). Crowding, on the other hand, has not been shown to enhance weight variation within a pen at slaughter (Kornegay et al. 1993).

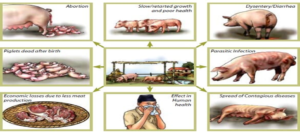

Effect of housing and space allowance on health of pigs

The effect of pig space allowance on pig health Increased aggression-related skin lesion scores are caused by limited space allowances (Turner et al. 2000, Anil et al. 2007). Furthermore, it was discovered that a limited floor space allowance increased the incidence of pigs being removed from pens owing to injury, ill health, or death. Pens with less room had lower joint swelling scores and lesions associated with fighting or biting (Smith et al. 2004). It has been suggested that there is a risk of disease when less than 0.5 m2 of lying area and less than 0.8 m2 of total space is provided per 100 kg of pig live weight (Kyriazakis and Whittemore 2006). Dedecker et al. (2005) found that the negative health impacts of reduced floor area are concerning from both an animal welfare and an economic standpoint, and that further research is needed. Kaswan et al. (2015) reported marginally higher skin lesion scores in the lowest space allowance group with no incidence of lameness, diarrhoea, or other diseases in the different floor space allowance groups, which was likely due to relatively higher space allocation even in the lowest space allowance group.

Fig : influence of housing and space allowance in swine on their health.

The influence of housing and space allowance on carcass features

Only a few trials have reported on the effect of space allocation on carcass back fat and % lean (Brumm and miller 1996). In all tests, the pigs with the least amount of space allocation had the leanest carcasses and the least amount of back fat depth. When compared to pigs with unrestricted pen space, a reduction in pen space allowance resulted in reduced back fat and dressing percentage (Morrison et al. 2003). Increased social pressure in pigs with limited pen space may have resulted in recurring stimulation of the sympathetic-adrenal medulla axis or the hypothalamic–pituitary adrenal axis, resulting in protein and adipose tissue catabolism (Dubeski et al. 1999). Thus, social stress in the confined pen space could have contributed to the slimmer pigs with lower dressing percentages (Morrison et al. 2003).

The influence of housing and space allowance on pig behaviour

The allocation of space is a key aspect in determining social rank (Baxter 1985). When pigs are confined in cramped quarters, the dominance hierarchy becomes less stable (Jensen,1982). Crowding can amplify social vices including tail biting, side nudging, and ear gnawing (Bryanand ewbank, 1980).

Conclusion

Given the rising human population and urbanisation, the majority of pig farmers, particularly those in peri-urban areas, are concerned about the efficient use of available land (space). The best usage of pen space without compromising pig production and well-being is critical for the pork sector. Crowding has been shown to have a negative impact on growth, feed intake, and FCR. However, for pigs, space is not as crucial as other resources, such as food and the environment. One of the most essential aspects in determining social standing is space allowance. It is found that, based on current practises, a floor space reduction of more than 33 percent in contrast to requirements can be suggested without jeopardising pig welfare. Investigations are needed to validate the floor space need for different types of pigs, in varied group sizes, and under diverse environmental conditions.

https://www.pashudhanpraharee.com/pig-farming-in-india-breeding-feeding-housing-management/

https://agritech.tnau.ac.in/animal_husbandry/ani_pig_housing%20of%20pig.html

REFERENCES

- Anil L, Anil S S and Deen J. 2007. Effects of allometric space allowance and weight group composition on grower-finisher pigs. Canadian Journal of Animal Science 87: 139–51.

- Basic Animal Husbandry Statistics (BAHFS). 2018. Department of Animal Husbandry, Dairying and Fisheries. Ministry of Agriculture, Government of India. Retrieved December 2, 2018 (http//www.dahd.nic.in).

- Baxter M. 1985. Social Space Requirements of Pigs: Social Space for Domestic Animals, pp 116–27. Kluwer Academic Publishers, Hingham, MA, USA.

- Bhat P N, Mohan N H and Sukh Deo. 2010. Pig production. Studium Press (India) Pvt. Ltd, Darya Ganj, New Delhi.

- Bhat P N, Mohan N H and Sukh Deo. 2010. Pig production. Studium Press (India) Pvt. Ltd, Darya Ganj, New Delhi

- Brumm M C and Miller P S. 1996. Response of pigs to space allocation and diets varying in nutrient density. Journal of Animal Science 74: 2730–37.

- Brumm M. 2010. Designing production facilities for pig comfort in Argentinian conditions.

- Cameron R D A. 2000. A review of the industrialization of pig production worldwide with particular reference to the asian region. Animal Health and Area-wide Integration. FAO, Brisbane, Australia.

- Cho J H and Kim I H. 2011. Effect of stocking density on pig production. African Journal of Biotechnology 10(63): 13688– 92.

- Gonyou H W, Brumm M C, E Bush J, Deen S A, Edwards T, Fangman J J, McGlone M, Meunier-Salaun R B, Morrison H, Spoolder P L, Sundberg and Johnson A K. 2006. Application of broken-line analysis to assess floor space requirements of nursery and grower-finisher pigs

- IS 3916(1966): code of practice for pig housing [FAD 5: livestock feeds, equipment and systems].

- Jensen P. 1982. An analysis of agonistic interaction patterns in group-housed dry sows-aggression regulation through an ‘avoidance order’. Applied Animal Ethology 9: 47–61

- Kaswan S, Patel B H M, Mondal S K, Dutt T and Verma M R. 2015. Effect of floor space allowance on the performance of crossbred weaner barrows. Indian Journal of Animal Research 49(2): 241–47.

- Kornegay E T, Lindemann M D and Ravindran V. 1993. Effects of dietary lysine levels on performance and immune response of weanling pigs housed at two floor space allowances. Journal of Animal Science 71: 552–56.

- Morrison R S, Hemsworth P H, Cronin G M and Campbell R G. 2003. The effect of restricting pen space and feeder availability on the behaviour and growth performance of entire male growing pigs in a deep-litter, large group housing system. Applied Animal Behaviour Science 83: 163–76.

- Petherick J C, Beattie A W and Bodero D A V. 1989. The effect of group size on the performance of growing pigs. Animal Production 49: 497–502.

- Petherick J C. 2007. Spatial requirements of animals: Allometry and beyond. Journal of Veterinary Behavior 2: 197–204.

- Prasad R, Singh A K and Singh L. 2011. Higher adaptability and economic return from pigs overshadows social taboos. Indian Research Journal of Extension Education 11(1): 103–06.

- Sharma P K, Saikia S and Baruah K K. 2004. Effect of stocking density on growth performance and feed efficiency of Hampshire grower pigs reared under identical feeding and management. Indian Veterinary Journal 81(3): 299–301.

- Sinha S K, Singh R A, Sharma B D and Dubey C. 1990. Effect of floor space on quantitative carcass characters of Large White Yorkshire. Indian Journal of Animal Sciences 60(8): 1006– 07.

- Smith L F, Beaulieu A D, Patience J F, Gonyou H W and Boyd R D. 2004. The impact of feeder adjustment and group size-floor space allowance on the performance of nursery pigs. Journal of Swine Health and Production 12(3): 111–18.

- Turner S P, Ewen M, Rooke J A and Edwards S A. 2000. The effect of space allowance on performance, aggression and immune competence of growing pigs housed on straw deeplitter at different group sizes. Livestock Production Science 66: 47–55.