Innovative Technology & Practices Transforming India’s Dairy Farming Sector

- Sridevi*, J. Violet Beaulah, Geetha Ramesh., S. UshaKumary, T.A. Kannan

*PhD scholar, Department of Veterinary Anatomy,

Madras Veterinary College, Chennai – 600 007.

India, which produced 24% of the world’s milk in 2021–2022, is currently the leading milk producer in the world. India’s milk output increased by 51%, to 221.06 million tonnes, during the years 2014 –15 and 2021–22. Milk production has risen by 5.29% in comparison to 2020–21. The top five milk producing states are Rajasthan (15.05%), Uttar Pradesh (14.93%), Madhya Pradesh (8.6%), Gujarat (7.56%) and Andhra Pradesh (6.97%). India’s dairy farming industry has seen the emergence of a number of cutting-edge technology and methods that are revolutionising the market. These innovative technologies and practices are meant to increase productivity, raise the standard of milk production, better health care facilities and superior germplasm.

The following are some of the innovative techniques and technologies influencing the evolution of India’s dairy farming industry:

- Innovations in Precision Nutrition:

The weather and the health of the cattle determine the feed. A sick or pregnant cow, for instance, could require additional nutrients. Cattle need extra glucose in their feed during hot and humid weather. To sustain maximum milk production throughout the year, a number of feed technologies create formulated feed additives, supplements, premixes, and base mixes. For instance, to make specially processed protein supplements that may be fed to calves to boost milk yield and quality, the National Dairy Development Board (NDDB) developed bypass protein technology. Using precision nutrition, cows are given a balanced meal that is specially designed to meet their unique nutritional needs. Additionally, there are digital feed monitoring solutions that can assist farmers in managing feed inventory, identifying the quality of feed, and comprehending the feeding habits of their cattle. By analysing the nutritional content of feeds and monitoring the health and performance of individual cows, technologies like near-infrared spectroscopy (NIRS) and real-time monitoring systems enable farmers to optimise feed composition and increase milk production.

- Innovations in Reproductive biotechnology: In breeding animal populations to decrease generational gaps and spread genetic material. In the dairy sector, biotechnology is a relatively new field. However, it is hailed as one of the dairy industry’s most revolutionary new developments. Dairy biotechnology has the potential to improve disease resistance in livestock, feed cows scientifically, use embryo transfer technology, perform artificial insemination, develop new molecules and vaccines for disease management and prevention in animals, produce dairy enzymes, proteins, and probiotics

- Artificial Insemination (AI), Embryo Transfer (ET), manipulation of In Vitro Fertilisation (IVF), cloning, and transgenesis have been created over generations

- These have the potential to significantly increase cattle productivity, along with sperm sexing, embryo sexing, transcriptomics, embryo genomics, and stem cell technology.

- Animal identification, recording and analysis of various types of data i.e., phenotpic, genomic and epigenomic data for selection of breeding stock using bioinformatic tools and finally manipulation and dissemination of germ plasma using biotechnology tools

- Innovations in Precision Technologies in the Dairy Industry

Milk composition can provide information about nutrition, metabolic state and health through changes in major and minor milk components. Milk sampling has the major advantage of being non-invasive and automatable, and the combination of routine sampling and the generalised use of MIR (mid-infra[1]red) spectrometry in dairy herd improvement programs focused on ‘simple’ protein, fat and lactose composition also now allows the simultaneous detection of more inform[1]active biomarkers such as ketone bodies and individual fatty acids

A number of integrated in-line/real time milk analysis technologies are available. Afimilk’s ‘AfiLlab’ system is able to measure the major milk components and milk coagulation properties by near-infrared analysis (NIR), and can be combined with the ‘Online Cell Counter’ for somatic cell count (SCC) based on the analysis of cell’s ADN by U.V. fluorescence Lattec’s ‘Herd Navigator’ focuses on milk biomarkers for the detection of oestrous (progesterone analysis), subclinical and acute mastitis and ketosis.

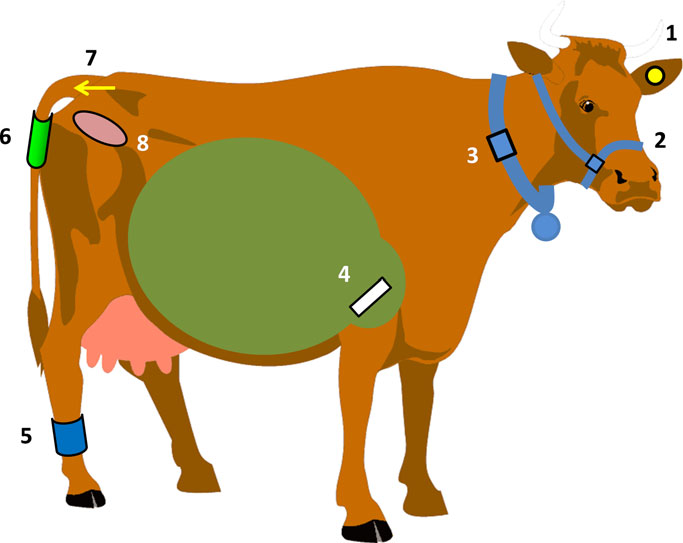

Neck mounted device utilising accelerometer and microphone technologies, wearable devices attached on cow collars or halters have been designed to track features like activity, rumination, and feeding and drinking times.

Leg-Mounted Devices is most popular method for tracking animal position proximity or using accelerometers to measure animal activity is to attach devices to the leg. These technologies, which were initially utilised for estrus detection applications, may be the earliest type of PLT to be applied in the dairy business

Ear tag technologies can track temperature, activity, rumination, feeding behavior, panting time and location. Accelerometers, proximity sensors, and skin temperature sensors are most often applied within these devices.

The reticulo-rumen bolus to track an animal’s activity, rumen temperature, and in some circumstances rumen pH, rumen boluses have been produced. Rumen boluses have only been employed occasionally on industrial farms, partly because of how expensive pH sensing is compared to other technologies. The cost and battery life of devices that only measure activity and temperature in the rumen are significantly lower. Rumen boluses with pH sensors have far lower battery lives than typical sensors, lasting just about six months. It is impossible to retrieve these gadgets further, and calibrating the sensors is difficult.

1) Ear tag, (2) Halter, (3) Neck collar with counterweight, (4) Reticulo-rumen bolus (in reticulum), (5) Rear leg pedometer, (6) Upper tail ring, (7) Tail head inject, and (8) vaginal bolus. (Source: https://www.researchgate.net/figure/Location-of-engineered-devices-for-in-situ-data-collection-in-a-cow-1-ear-tag-2_fig3_303499298).

Precision dairy farming, also known as “smart dairying,” refers to the use of Information and Communications Technologies (ICTs) to measure and use physiological, behavioural, and production indicators of individual animals for management decisions that result in profitable and sustainable production of high-quality milk. Maximising animal performance, early detection of individual animal illness, early detection of herd-level health and production issues, improving farm efficiency, and minimising resource consumption at the farm are the main goals of smart dairying to simplify many elements of dairy production, automation technologies are being used.

- Health monitoring: Sensors and techniques for heath monitoring are well developed for dairy production under confined conditions. The productivity, longevity, and reproductively of cattle are all impacted by health issues. However, farmers can now measure, monitor, and regulate cattle’s health, nutrition, behaviour, pregnancy, milking frequency, milk output anomalies, and activity level in real-time thanks to wearable animal gadgets that are similar to human fitness monitors. The cattle’s ears, tail, legs, neck, or any other portion of their bodies can be implanted with these sophisticated animal trackers. Sensors have been able to detect 80% of health problems related to ketosis, locomotion and lameness at least one day sooner than the farm staff by analysis of short-term feeding.

- Oestrus, mating, calving are based on activity-recording of one sort or another using tri-axial accelerometers. They are offered to wear as an ear tag , nose halter, neck collar or leg (preferably rear) pedometer

- Use of the pedometer and advanced time series analysis to detect oestrus in dairy cows has been quite successful.

- Calving detection is monitored by changes in tail position with devices attached to the tailhead containing accelerometers by the dramatic change of temperature of a vaginal device using thermistors

- Software for managing herds: Having the capacity to digitally store herd data is a useful tool for all farms and a requirement for those who want to use RFID to improve farm management. Farmers can save information about individual cows in a database using tools provided by herd management software. Data can be entered manually or automatically into this software programme with the help of additional digital equipment (like milk metres and cow weight scales) connected to this database. Many features of herd management software are practically unachievable with conventional paper-based methods.

- Automated milking equipment ensure hygienic milk output while reducing labor-intensive hand milking.

Milk metres is crucial in a business where milk is the main product this useful capability is provided by measure the quantity of milk each cow produces during each milking session. This data must be automatically stored in the herd management database in order to be of any use. Milk metres can also provide other data that should be saved in the database, such as the time the reading occurred, the cow’s number, and the length of the milking. These details provide reliable documentation of each cow’s milking session.

Milking machines is a crucial piece of machinery for all contemporary dairy businesses. This mechanism regulates the suction and sucking motion of the milking cups that are fastened to each cow’s teats. This method may produce a cow’s whole milking history and milking style when used with RFID technology. It is possible to keep track of each cow’s milk production in quarters when used with a flow metre. The requirement for human presence at the milking site has been completely eliminated by recent advancements in the usage of automatic milking devices. The robotic milking systems (like the DeLaval AMRTM automatic milking rotary and the DeLaval VMSTM voluntary milking system), allowing the farmer and their staff to focus on other crucial aspects of their dairy operation, such as feeding, breeding, health, and hygiene. DeLaval was the first company in the world to introduce an automatic milking rotary. Utilising data sets for distinct udder quarters, automatic or robotic milking systems reduce the likelihood of intra-mammary infection (IMI).

- To improve agricultural operations, automated feeding systems, automated feed-dropping control units, automated watering, manure management systems, and ventilation control systems are also being used.

- Feed troughs with measuring capability

- IoT technologies are used in dairy farming to track a variety of characteristics in real-time, including temperature, humidity, water use, Animal behaviour sensors and Thermoregulation and Heat Stress

- Identification: Animal identification systems are now at a highly advanced stage of development and marketing. There are numerous RFID-based systems available, some of which function reasonably well and have been adopted at the national level.

- Digital device network: To enable device connection with RFID readers and the central herd management software, a type of digital network is necessary. Creating such a network can be done in one of three ways: wired, wireless, or hybrid. Each has advantages and disadvantages of its own, and the final decision about the implementation method will be based on the traits and preferences of specific dairy farms. All devices are connected to a network via a network cable in a totally wired network, which is unable to support wireless connections or wireless devices. This will make it possible for a variety of fixed or mobile devices to connect directly to real-time data in the herd management database. These include commonplace computer network gadgets including laptops, desktop computers, printers, and smartphones. These also offer the crucial connections to many other equipment used on dairy farms, including RFID readers, milking controller units, feed management units, drafting gates, and a wide range of other devices that can be set up to run on computers or need access to herd data to function. A network that is partially wireless or partially wired can be created as an alternative.

- Innovations in Dairy health care diagnostics and therapy: Utilising diagnostics that should be Simple, Reliable, and Economical allows for the diagnosis of infectious diseases. A wide range of contemporary molecular diagnostics, in addition to the standard tests used, are commercially available for the identification of bacterial, viral, mycotic, and parasite disorders affecting dairy cows. PCR (Broad range PCR, Multiplex PCR, Nested/semi nested PCR, RT-PCR, Real time PCR), Blotting (Southern, Northern and Western), and ELISA (Indirest, Sandwich, Competitive and Avidin Biotin) are a few of the frequently used molecular diagnostic procedures. These diagnostics include the Lateral Flow Assay (LFA), an enzyme-linked immunosorbent assay (ELISA) based on plates or strips, polymerase chain reactions (traditional or real-time), immunofluoresence tests, glutination tests, and immunological diffusion.

- Dairy Data Analytics: Platforms for data analytics are being used to analyse vast amounts of data gathered from numerous sources, such as genetic information, milk production, feed composition, and health records. Farmers may better manage their herds by identifying patterns, anticipating disease outbreaks, maximising breeding programmes, and more thanks to this information

- Blockchain-based Customer Product Traceability: Increasing numbers of dairy producers, suppliers, and other stakeholders are using blockchain technology to provide customers with real-time information on their goods. Customers can obtain information on the milk’s origin, including how and where it was gathered and packaged, how old it is, what kind of transportation and cold milk chain facilities were used, etc., by scanning a QR code that has been printed on the packaging with their mobile devices.

- Technology for Supply Chains depends on so many variables, including storage temperature, the availability of cold chains, the weather, perishability/shelf life, first and last mile distance, packaging, etc., the supply chain for the dairy business in India is highly complex. The problems with the supply chain are also exacerbated by how disorganised and fragmented the dairy business is in India. The Indian dairy supply chain is, nevertheless, experiencing a lot of technical advancements. Consider supply chain startups with Indian roots include Trinetra Wireless, MilkManApps, and Stellapps.

- Cold Chain Infrastructure: To preserve the quality and freshness of milk during shipping and storage, a strong cold chain infrastructure must be developed. In order to make sure that milk reaches consumers in a safe and hygienic state, cold storage facilities, refrigerated transport vehicles, and milk chilling centres are being created.

- Farmer Producer Organisations (FPOs): FPOs are essential for uniting and empowering dairy producers. FPOs give small-scale dairy farmers access to loans, technical assistance, and marketing support, helping them to increase productivity and secure higher milk prices.

Conclusion: The dairy farming industry in India is being revolutionised by these technology and methods, which also increase production, profitability, and sustainability. Farmers can increase milk output, reduce resource waste, and protect the wellbeing of their animals by implementing these technologies, which will ultimately help the country’s dairy industry expand and thrive.