Poultry Production in Environmentally Controlled (EC) House

Ankit Sharma*, Shashikant, Anupam Kumar Azad, Sumit Gangwar, Londhe Arvind Sudhakar, Gyan Deepak

Department of LPM, GBPUAT, Pantnagar

*Corresponding Author email: ankit291994@gmail.com

The environment provided to poultry flocks has a great bearing on flock performance and profitability. Basic environment consists of feed, lighting, air (temperature, humidity, pathogen concentration and ammonia), water and litter quality. Birds are homoeothermic. The internal body temperature in the adult chicken is 105°F-107°F (40.6° and 41.7°C). Newly hatched chick- 103.5°F (39.7°C) and increases daily until it reaches a stable level at about three weeks of age. The poultry thermal comfort zone, or thermoneutrality, depends on species and age, with younger birds responding better to warmer temperatures. Poultry feed conversion deteriorates when temperatures are outside the recommended comfort zone. Bird produces heat that must be lost to the environment to maintain constant body temperatures.

Disadvantages of free-range system of housing

- Loss of egg may be a big problem; hens lay eggs everywhere.

- Predatory animals cause loss of poultry birds.

- Infectious diseases and parasites problem may occur.

Disadvantages of semi-intensive system of housing:

- High cost for fencing.

- Need for routine cleaning and removal of litter material from the pen.

Environmentally controlled house (EC house)

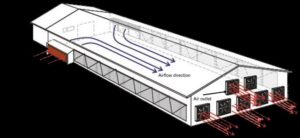

It is one in which inside conditions are maintained as near as to the bird’s optimum requirements. A closed building, longitudinally preferably east to west, big exhaust fans on west side, evaporative cooling pads on east side along with automatic feeding and drinking systems inside, in order to maintain proper ventilation, temperature, relative humidity and lighting program.

Control over microenvironment

- Ventilation:

Negative pressure ventilation:

Types of Negative-Pressure Ventilation Operations

- Minimum ventilation – (also called just “power ventilation” or even “power vent”)- operated on a timer and used for cooler weather and/or smaller birds.

- Transitional ventilation – operated on thermostat or temperature sensor and used for heat removal when wind-chill (tunnel) cooling is not needed or desirable.

- Tunnel ventilation.

Components of mechanical ventilation

Fans, openings, heaters (radiant, space and make-up air heaters) and controls. Controls are needed to adjust ventilating rates (fan controls), supplemental heating rates, and the air velocity rates (fan controls), supplemental heating rates, and the air velocity through openings as weather, bird age and size change.

2 Coooling the house

- Low pressure fogging system:

- Pad –and- fan system:

- Pressurized system

- Vacuum system

- Fog –and- fan system

- High pressure nozzel system

3 Temperature control in environmentally controlled house

Different types of heaters are used for supplemental heating in poultry houses including radiant, space, and make-up air heaters.

4 Feeding in environmentally controlled house

Feed monitoring systems are available to measure the amount of feed consumed by bird. Normally 7- 8 times per day feeding occur in environmentally controlled houses.

5 Lighting management in environmentally controlled house

Environmentally controlled house must be lightproof; that is, no outside light should be allowed to inter in the building. A monitoring and control system should provide scheduling of lights that is easy to use. It is especially important breeding facilities for precise lighting schedules to be followed. A system than can pre-program lighting schedules over the life of the flock is very useful for management. It is also important to provide the desired intensity of light.

EC houses in broiler production

Modern climate-controlled housing and equipment make it possible to control the microclimate provided in technologically advanced commercial broiler production. But such houses are expensive to build and operate and require a large turnover of birds to make them viable (Glatz and Pym, 2013). Because of the lower investment costs, the conventional open-side-elevated housing for broilers still persists.

Tunnel Ventilation Properly ventilated housing is essential for profitable poultry production. There are basically five reasons why we must ventilate poultry houses: 1) remove heat 2) remove excess moisture 3) minimize dust and odors 4) limit the build up of harmful gases such as ammonia and carbon dioxide and 5) provide oxygen for respiration. Of these five, the most important are removing built up heat and moisture. The time of the year determines which of these is of primary concern (Bucklin et al., 2012). All poultry houses need some form of ventilation to ensure an adequate supply of oxygen, while removing carbon dioxide, other waste gases and dust (Glatz and Bolla, 2004). Farhadi and Hosseini (2014) noticed that bird performance including live body weight, feed intake, feed conversion ratio, mortality rate, production efficiency index and litter pH, moisture content and air ammonia levels were not significantly affected by types of the houses. Chickens grown in the EC house, although raised at higher stocking density (20 vs 16 birds/m2) than conventional house, had numerically lower mortality rate and greater production efficiency index. This may be probably due to improved environmental conditions through proper ventilation applied in environmentally controlled condition modern house than conventional house.

Tunnel ventilation is the best accessible management tool to prevent heat stress and mortality in broilers during hot periods of year (Lacy and Czarick, 1992). Lott et al., (1998) showed that broilers were raised in a tunnel ventilation system (higher air velocity on the birds) presented better weight gain and feed conversion ratio than the birds raised in a conventional system. In some studies, subsequent decline in air quality within poultry house have been reported by increasing stocking density (Zuidhof et al., 1995; Dawkins et al., 2004). Zuidhof et al., (1995) reported that subsequent decreased air quality due to stocking density increases; negatively affected turkey performance and increasing ventilation rate reduced the negative effects of increasing stocking density on birds. Bilal et al. (2014) compared the growth performance of broilers housed under two different rearing systems (cage and floor) placed in three housing zones (near vent, middle and near variable speed fans). The body weight (2266.81±53.4g) feed intake (4218.50±94.98 g), performance efficiency factor (284.76±7.16), FCR (1.90±0.00) were found to be best near vents followed by middle and fan area.

EC houses in layer production

For controlled-environment housing of layers, multi-tier cage systems are common. Most large-scale commercial farms use controlled-environment systems to provide the ideal thermal environment for the birds (Glatz and Bolla, 2004). Birds’ performance in controlled-environment sheds is generally superior to that in naturally ventilated houses, as the conditions can be maintained in the birds’ thermal comfort zone. Achieving the ideal environment for birds depends on appropriate management of the poultry house. Bharathi and Senthazai (2020) reported that investment cost per bird is higher in EC housing system whereas the returns are significantly higher due to higher standards of production and lower mortality.

Conclusion

Climate controlled condition improves the performance of birds with better FCR and livability that translates to higher income than in conventional type. Broilers reared on floor near vent area exhibited better growth performance with optimum feed intake leading to best FCR as compared to those of cages placed in the middle and fan area. Power cost is the most expensive component in operating a climate-controlled broiler house. The investment cost per bird though higher in EC housing system the returns are significantly higher on a long run due to higher standards of production and lower mortality. In tropical climatic conditions EC will be future trend in due to unpredictable climatic changes.

References

Bharathi DI, Senthazai MS. 2020. Comparative prefeasibility analysis for large scale layer farm under open sided and environmental control house. International Journal of Science, Environment and Technology, 9(3): 479 – 484.

Bilal K, Mehmood S, Akram M, Imran S, Sahota AW, Javed K, Hussain J, Ashfaq H. 2014. Growth performance of broilers under two rearing systems in three different housing zones in an environmentally controlled house during winter. The Journal of Animal & Plant Sciences, 24(4): 1039-44.

Bucklin, R.A., J.P. Jacob, F.B.Mather, J.D. Leary and I.A. Naas. 2012. Tunnel Ventilation of Broiler Houses. Retrieved from http://edis.ifas.ufl.edu/ Aug. 4, 2013.

Dawkins, M. S., C. A. Donnelly, and T. A. Jones. 2004. Chicken welfare is influenced more by housing conditions than by stocking density. Nature. 427:342–344.

Farhadi, D. and S.M. Hosseini. 2014. Comparison of Broiler Performance in Two Conventional and Environmentally Controlled Modern Broiler Houses in Tropics. Global Journal of Animal Scientific Research. 2(3): 190-196.

Farhadi, D. and S.M. Hosseini. 2014. Comparison of Broiler Performance in Two Conventional and Environmentally Controlled Modern Broiler Houses in Tropics. Global Journal of Animal Scientific Research. 2(3): 190-196.

Glatz, P. and R. Pym. 2013. Poultry housing and management in developing countries. Poultry Development Review. FAO-UN. Retrieved from http://www.fao.org/ docrep/ on August 21, 2013.

Glatz, P.C & Bolla, G. 2004. Production systems, poultry. In Encyclopaedia of meat sciences, pp. 1085 – 1092. Oxford, UK, Elsevier.

Lacy, M.P., and Czarick, M. 1992. Tunnel- ventilated broiler houses: broiler performance and operating costs. J. Appl. Poult. Res. 1:104–109.

Lott, B.D., J.D. Simmons, and J.D. May. 1998. Air velocity and high temperature effects on broiler performance. Poult. Sci. 77:391–393.

Zuidhof, M.J., J.J.R. Feddes , F.E. Robinson and C. Riddell. 1993. Effect of ventilation rate and stocking density on turkey health and performance. J. Appl. Poult. Res. 2:123–129.

https://www.pashudhanpraharee.com/environmental-controlled-houses-in-poultry/

https://www.poultryindia.co.in/environmentally-controlled-poultry-shed-farming/