Practical Approaches to Broiler Management in India

Broiler chicken farming is one of the most profitable livestock business in India. Broiler farming can be done in small scale poultry farm to large industrial broiler farm. Discover how to plan and set up a broiler farm in India.

Broiler chicken is the most popular bird in poultry farming in India. Broilers are reared for commercial marketing of the chicken meat. Broilers are small chickens that are 5-6 weeks old. They are tender with flexible bones. Broiler farming need very little investment since they can be grown and marketed within six weeks.

The tender meat of a young chicken grown from a hatch is called broiler. In its broadest sense, broilers are chicken raised specifically for the meat purpose from its hatch. It is an important protein source. It also contains vitamins and minerals in sufficient amounts. Owing to the technological advancements and commercial development there are specially developed broilers available. These breeds are different from egg layering birds used in layer poultry farming. These grow quickly and have a high efficiency of conversion. In addition, poultry manure has a very high fertilizer value that can be used for increasing the crop yield in organic farming.

Broilers are those chickens which are reared for meat purpose. They achieve their marketable weights very early, by 5-6 weeks. Layers are those chickens which kept solely for egg production. They start lying at 20th week of their life and continue till 72nd week.

Small management tips can bring big changes in overall profitability.

Housing

One should first select a well-drained site that has plenty of natural air movement.

Oriented on an east-west axis to reduce the effect of direct sunlight on the sidewalls during the hottest part of the day

Good ventilation should be available; to achieve this width of the farm should be 25ft and do not exceed 30ft.

While making shed local climate, cost effectiveness, durability & provision of comfortable environment in all the seasons should be considered.

Durability of farm is very important especially in coastal areas where cyclones falls on land and plains of north India where frequent dust storms are encountered in summer season. Farm damaged in storms could wipe out total profitability of a year in one go.

In this figure farms made of bamboo and wood are not durable, they are very destined to be destroyed even in moderately strong winds.

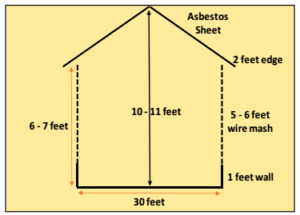

Sufficient overhang to the roof is necessary to provide shade and prevent entry of direct rains into the house. This overhang should be 0.6m (2ft) long.

Roofing material should provide good insulation from heat and should not allow rain water to enter the house. Houses constructed underneath the shadow of trees get better cooling effect.

In open houses sufficient height of the roof is to be maintained to facilitate ample air exchange and to maintain optimum temperature conditions to the birds. Height in the middle of the farm should be 9 to 11ft and on sides should be 6 to 7ft.

Lighting should be fitted with a view to provide an even distribution of light throughout the house.

Figure on right hand side – Farm should preferably be planned and orient in open areas but to provide better environment farmer can plant trees.

Correct stocking density is essential to the success of a broiler production system by ensuring adequate room for optimal performance; in warmer climates a stocking density of 30 kg/m2 is closer to ideal. India comes under warmer climate as 8 out of 12 months are warm.

Thumb rule: first 10 days 3chicks in 1sqft, second 10 days 2chicks in 1sqft and 3rd days 1 bird per sqft and after 30 days 1 bird per 1.2sqft. The partitions are provided in the farms to have pens which can accommodate 600 to 700 birds.

In figure – Double Story Poultry Farm – Farmers can made these type of farms to better utilize the available land. One thing we should take care is to ensure proper ventilation because if height of ground floor is less than it would hamper ventilation. Also keep in mind that all birds (in upper and lower sheds) should be of same age. One major problem in these farms are their cost of erection because it needs strong foundation and concrete roof which could sustain the overlying structure.

Alternate Row of Feeder and Drinkers in Broiler Farm

Equipment

Providing clean, cool and fresh water with adequate flow rate is fundamental to good poultry production. Without adequate water intake, feed consumption will decline and bird performance will be compromised. Both closed and open watering systems are commonly used.

From day old to first 10 days of age a minimum of 16 – 20 chick (mini) drinkers should be provided per 1000 chicks. As the broilers grow older chick drinkers are to be replaced with Bell type drinkers at the rate of one drinker per 70 birds.

| These drinkers should be placed evenly throughout the house so that birds need not walk more than 8 feet to drink water.

Drinkers should be checked for height on a daily basis. Height of the drinkers is such that the base is ¡n level with the bird’s back. |

Bell or Cup Drinkers (Open Systems)

While there is a cost advantage of installing an open drinker system, but problems associated with open drinker system is litter quality, condemnations and water hygiene are more prevalent. Water purity with open systems is difficult to maintain as birds will introduce contaminants into the reservoirs resulting in the need for daily cleaning. This is not only labor intensive but also wastes water.

Bell drinkers should provide at least 0.6 cm (0.24 in.) per bird of drinking space. 1 drinker per 70 birds is required.

Nipple Systems (Closed systems)

High flow nipple drinkers: They provide a drop of water and have a cup to catch any excess water. Generally 10 – 12 birds per nipple are recommended.

Low flow rate nipple drinkers: Do not have cups, Generally 10 birds per nipple are recommended.

Birds should not have to travel more than 8 ft. to find water.

Nipples should be placed at a maximum of 35 cm (14 in.) centers.

| Water consumption should equal approximately 1.6-2 times that of feed by mass, but will vary depending on environmental temperature, feed quality and bird health.

· Feed consumption decreases by 1.23% for every increase in 1 degree in temperature above 20 °C. · Water consumption increases by 6% for every increase in 1 degree in temperature between 20-32 °C. |

Feeding System

Regardless of which type of feeding system is used, feeding space is absolutely critical. If feeder space is insufficient, growth rates will be reduced and uniformity will severely compromised.

50-70 adult birds per 33 cm (12 in.) diameter pan are recommended.

Supplemental feeders (additional chick feeders) should be provided for the first 7 to 10 days in the form of paper, trays or lids.

Trays should be provided at a rate of one per 100 chicks.

If using paper, the feed area should be a minimum of 25% of the brooding area. 50-65 grams of feed per chick on the paper is recommended. In early 2 or 3 days paper could be used but it should be avoided as it increases wastage. I recommend that trays are better alternative, when chicks arrived in farm provide feed on paper for 6 to 8 hours and then switch to trays.

Very Imp. Point: It is of utmost importance that the additional feeders should not run empty as this will reduce yolk sac absorption. It means that feed should make available as soon as chicks arrived in the farm. Early feeding increases yolk utilization and reduces chances of yolk problems.

Additional feeders should be refreshed (refilled) three times daily, until all the chicks are able to gain access to the main feeding system. This generally occurs at the end of the first week.

Litter Management

Rarely given sufficient emphasis, litter management is another crucial aspect of environmental management. Correct litter management is fundamental to bird health, performance and final carcass quality which subsequently impacts the profit of both growers and integrators.

- Racking should be done every week

- Avoid re use of litter

- If litter is seemed to be damp add lime powder to keep it dry.

8000 broiler bird farm with good litter and ventilation management

Preparation of poultry house

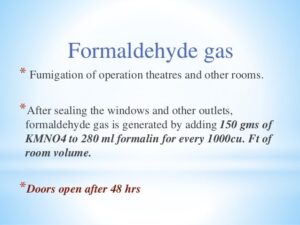

Shed should be thoroughly cleaned and disinfected before arrival of chicks. Fumigation with Potassium permanganate and formaldehyde (1:2) can be successfully used for disinfection of poultry house.

This method produce a violent chemical reaction that generates considerable heat and releases formaldehyde gas. Recommended dosage is 20 grams of Potassium permanganate is to be added to 40 ml of Formalin. Because of the violent chemical reaction, never use more than 1.2 liters of formalin in any one container. The container should be sufficiently bigger, at least 3 times the volume of disinfectant to prevent the mixture from bubbling over. The container must be placed on concrete or metal surface and not on litter material. Potassium permanganate is to be added to formalin and not vice versa.

Now a days fogging guns are available that would done fogging in just 1hr. X185 of venkys should be used for fogging.

Brooding and Other Management Tips

- Golden rule of broiler farming is that – “single age birds should be present at one site”

- Second farm of another age at same location should be atleast 500m away.

- Chicks from one source should be placed in a house

- Houses, the surrounding areas, and all equipment must be thoroughly cleaned and disinfected before the arrival of the bedding material and chicks

- 2 days before the arrival of chicks litter should be spread evenly on floor (2-4inches layer thick)

- Place newspapers on the litter in brooding area

- Place brooder guard and maintain proper temperature before arrival of chicks.

- Chicks are to be placed immediately in to brooding area upon arrival. Delays in placement can contribute to the dehydration of chicks, resulting in higher chick mortality and reduced growth rate.

- Take sample chicks weight for record purpose.

- Dim house lightsduring chick placement to help calm the chicks and reduce stress

- Chick boxes should not be stacked one above the other in the brooding area and empty boxes remove from farm quickly

- Four 60-watt bulbs suspended 6 inches above the floor, & a brooder guard of 5 feet radius along with 4 drinkers and 4 trays of feeding is sufficient for 300 chicks.

Management of day old broiler chicks

- Lights should be brought to full intensity within the brooding area once all chicks have been placed.

- Allow one to two hours for the chicks to get acclimatized to the new environment and then check all systems and make adjustments if necessary.

- Monitor the distribution of the chicks closely during the first few days.

- As newly arrived chicks are under transportation stress. Offer them 2 to 3% jagerry solution and add liquid vitamin supplement in jagerry solution to combat stress and improves growth.

- However unnecessary large amount of jaggery usually causes early diarrhea in chicks and hamper villus growth in intestine. It also helps in growth of unwanted bacteria in intestine which causes Yolksac infection and early chick mortality.

- After 3 hours of feeding 90% of the chicks must be eating the feed (Check the crop)

- Chicks should be scattered all over the place when the temperature is just right.

- In the beginning , feeder are kept full, however after ensuring that the birds are eating its level may be kept at 2/3 height. Feed should be added twice a day.

Brooding is the initial rearing stage of poultry. It is very crucial period in the life where chicks are susceptible to various environmental stresses, below chart brooding temperature is given. Chicks cannot regulate their own body temperature until they are around 12–14 days of age. Ideal body temperature must be attained by providing optimal environmental temperature. Preheating the house is vital as floor temperature at chick placement is as important as air temperature. Stabilize temperature and relative humidity for at least 24 hours prior to chick arrival.

Weekly temperature chart of brooder

| Week | Temperature | |

| I | Day 1 | 33 – 35°C |

| Day 2 | 32 – 33°C | |

| Rest of the week | 30 – 32°C | |

| II | 28 – 30°C | |

| III | 26 – 28°C | |

| IV | 24 – 26°C |

Three hours after placing the chicks in the brooder, when most of them having water/jagrrey solution, sprinkle pre – starter or maize grit on paper. Remember provided feed in less than 8 hours from time of hatch and water first for about 3 hours before the feed is given.

On 4th day, increase brooder area and height of brooder.

Floor space requirement

| Days | No. of chicks / sq ft |

| 1 – 10 days | 3 |

| 11 – 20 days | 2 |

| 21 – 30 days | 1 |

- For heavy birds 1.25 to 1.5 sq ft area is provided per bird.

- Prevent overcrowding and dusty environments. This will lead to respiratory disease.

- On 6thday papers can be removed & no. of feeders and drinkers should be increased & make 3 to 4 feeders/drinkers per 100 birds.

- On 7thday brooder guard can be removed, brooder can keep upto 3rd week in winters.

- In summers open house brooding could be done

- As birds grow ventilation becomes very important. Keep the curtain open throughout the day. Keep open in the night also if wind drafts are not so strong.

Water management

- Provide 30 drinkers per 1000 birds – minimum water space requirement 1 inch up to 4 weeks, 2 inch after 4 weeks.

- Usually bird drinks 2-3 liter of water for each kg of feed it consumes.

| Water Consumption in liters per 1000 birds at different temperatures | ||||

| Age (in days) / Temp | 70oF/21.1oC | 80oF/26.7oC | 90oF/32.2oC | 110oF/43.3oC |

| 0-7 | 27 | 28 | 32 | 78 |

| 8-14 | 72 | 85 | 122 | 216 |

| 15-21 | 108 | 153 | 248 | 324 |

| 22-28 | 144 | 200 | 324 | 432 |

| 29-35 | 184 | 256 | 400 | 552 |

| 36-42 | 221 | 302 | 464 | 663 |

| 43-49 | 256 | 340 | 510 | 786 |

| 50-56 | 280 | 352 | 536 | 840 |

Feed management

- Feed continuously to attain early market weights

- Give broiler starter up to 25 days of age (800g to 1kg body weight)

- Give broiler finisher feed from 26 days of age till marketing

Feeder space requirement

- 0 – 14 days – 1 inch per bird

- 15 – 42 days – 2 to 2.5 inch per bird

- Remember, methionine and lysine are the most limiting amino acid which limits growth in early days. To combat slow growth in early phase of broiler’s life give proper amount of these essential amino acid.

- Broiler performance is calculated by using “FEED CONVERSION RATIO” or FCR which is total feed consumed in kg / total live weight gain in kg.

- FCR of 1.6 or less at 2Kg B.Wt is economical.

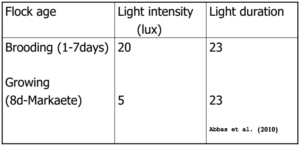

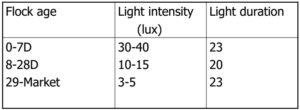

Lighting Requirements

Option 1

Option 2

Broilers performance standards for VenCobb 400Y

| Age weeks | Av. Weight (g) | Mortality % | Feed cumulative (g) | Feed conversion |

| 1 | 195 | 0.75 | 165 | 0.85 |

| 2 | 430 | 1.25 | 465 | 1.08 |

| 3 | 860 | 1.75 | 1040 | 1.21 |

| 4 | 1410 | 2.00 | 1890 | 1.34 |

| 5 | 2000 | 2.75 | 2940 | 1.47 |

| 6 | 2625 | 3.5 | 4200 | 1.60 |

Broilers performance standards for VenCobb 430Y

| Age weeks | Av. Weight (g) | Mortality % | Feed cumulative (g) | Feed conversion |

| 1 | 195 | 0.75 | 156 | 0.80 |

| 2 | 440 | 1.25 | 450 | 1.02 |

| 3 | 870 | 1.75 | 1045 | 1.20 |

| 4 | 1420 | 2.00 | 1890 | 1.33 |

| 5 | 2020 | 2.75 | 2930 | 1.45 |

| 6 | 2650 | 3.5 | 4190 | 1.58 |

Procedure of Vaccination

- Vaccination is very important aspect of broiler farming. It prevent deadly diseases outbreaks in the farms. Many farmers often ignored vaccinations due to which they suffered huge losses. Following points should be remembered while performing vaccinations.

- One day before immune boosting supplement like Vit E and Se should be given in double dose.

- Vaccine should be done in cool hours of the day. In summers it should be done in evening and in winters it should be done in the morning.

- On the day of vaccination do not add any sanitizer in water.

- 2 hours before vaccination drinkers should be lifted so that birds feel thirsty at the time of vaccination and drink vaccinated water within in few hours.

- Now take an estimate of the water in which vaccine has to be given. Add 1000 doses in 25 to 30liters of water and before adding vaccine mix 2g milk powder per liter of water. Mix vaccine thoroughly and give it in drinkers and not in tank. Add 2 drinkers extra per 1000 birds.

- If you are giving vaccine in tank than take care of dosage and try to compensate by adding extra dosage. It is better to install small sub tank in the main line of nipple pipeline. Add medicine or vaccine in that sub tank, it will ensure proper dosing and reduce wastage.

- After vaccination again provide immune boosting supplement.

Vaccination schedule for broilers

| Age(Days) | Vaccine | Route |

| 5-6 | Ranikhet (F1 or B1) | Eye drop or intranasal |

| 12-14 | Gumboro intermediate | Drinking water |

| 18-21 | LaSota | Drinking water |

| 24-30 (not always req) | Gumboro intermediate | Drinking water |

In case you are facing IB variant problem in your area or farm than you can use IB+ND vaccine on 5th day and then 21st day.

Principles of Poultry farming

Compiled & Shared by- This paper is a compilation of groupwork provided by the Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request