Secure Food Safety and Quality through Traceability System in India : Requirements, Methods and Challenges in Indian Food Industry.

Over past few decades Indian food industry has grown many folds. Globalization of food production and distribution has not only added the opportunities for food Industries but also along the increase in complexity in processing. Growing consumer awareness and increased complexity of supply chains, traceability system has gained a lot of importance.

Indian context of “Farm To Fork” is not simple and often involves multiple, complex steps till it reaches to consumer. Today consumers are not only conscious about the health and wellness but also about the transparency and information of food products with respect to its quality and safety. Customer/ consumer complaints, incidents of food recalls are deeply impacting the consumers confidence and accordingly their choices. So preparedness of industry in terms of information, its access and systems for its retrieval related to products has become much more significant.

Traceability system enables food processing industries to rapidly respond to a situation by identification and segregation of affected/unsafe food product from entire supply chain. It also helps organizations to systematically document all the information and locate the potential cause of nonconformity to take effective corrective actions. It enhances the transparency over the journey of food product from “Farm To Fork” or in Indian scenario from “Farm To Fingers”.

Basic elements in food traceability system are:

1 Identification of units/batches of ingredients and products.

- Recording of information on handling and movement of units/batches of ingredients and products.

- A system which will link this data and transferring all relevant information to the next element in supply chain.

Food traceability : Regulatory and Food safety standard’s perspective:

All the international food safety standards like BRC, IFS, SQF, FSSC 22000, ISO 22000 have the requirements related with food traceability to ensure food safety.

GFSI (Global Food Safety Initiative), ensuring the harmonization of food safety standards also covers system of traceability as one of the bench marking criteria.

European Union makes it mandatory for all manufacturers retailers brand owners to establish the system of traceability. Section 201 of FSMA ( Food Safety Modernization Act) published by USFDA addresses traceability which aims to focus on preventing the contamination rather than responding to it. This also applies to all food products imported in US to pass increased scrutiny under FSMA. China food safety law 2015 places more focus on supervision and control in every step of food production distribution sale recall trading including third-party trading platforms and e-commerce platforms. Australia and New Zealand under the joint Australia New Zealand food standard code focuses on lowering food borne illnesses by strengthening food traceability systems in food industries. With this context the introduction of Food Safety and Standards (Food Recall Procedure) Regulation 2017 has been instrumental for food safety. This regulation has the objective of easy removal of recalled food product, dissemination of information to concerned customers and consumers and ensure retrieval, destruction or reprocessing of food under recall. Now with recent food safety and standard food recall procedure regulation 2017,the responsibility of ensuring food safety has widened by extending the scope of recall covering all FBO and making each trading partner responsible for it. Also looking at exponential increase in E-commerce and online trading businesses FSSAI brought online businesses operators under coverage of FSS act.

Common traceability systems used in India:

1 Document based traceability

2 Bar code

3 RFID (Radio Frequency Identification)

- ICT (Information and Communication Technology)

5 WSN (Wireless Sensor Network)

6 Block chain Technology

- Document based traceability:

Small industries, manufacturers and other elements in supply chain use this simple and manual system for traceability. They keep all the information related to purchase, issue, distribution of stock and communication of information by writing it in documents. Apart from being a time consuming method there are chances of manual errors as well as tempering of data in such methods. This method is implemented by using alphanumeric codes and decoding the information related to products like date of manufacturing, month of manufacturing, location of manufacturing etc.

- Bar code:

Many of the food processing industries are using bar codes and 2D Quick Response (QR) code in order to enhance traceability system. Bar code is an openly machine-readable data which is printed over the objects which by means of electrical bar code readers can be easily encoded, stored and retrieved for information. First ever bar code was used in Wrigley Chewing Gum pack in 1974 and since then the bar code have played important role in food traceability. Use of bar code is growing rapidly with use of smartphone technology to get information directly by consumers.

3.RFID Radio Frequency Identification

RFID tagging for identification of animals by numbers is used for dairy and Other industries. RFID can trace the object therefore it can overcome the loopholes of traditional manual method used in traceability. RFID is used to record all the events automatically and get information about the food production by household devices.

4.ICT tools (Information and Communication Technology)

With the help of different ICT tools, which provides easy solution to farmers, traders, suppliers and manufacturers. ICT provide fast, reliable, efficient service and real-time information in terms of quality and quantity of food products. There are various ICT tools used in traceability solutions by government sector like APEDA and private sectors in food processing industries in India.

Example:

Grapenet for grape traceability for grapes Exports.

Anarnet for traceability in supply chain management of pomegranate.

Tracenet for organic food products traceability.

Peanut.net for peanut supply chain

- WSN (Wireless Sensor Network)

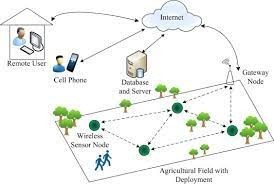

WSN consists of integration of different sensors connected through wireless technologies for non centralized wireless communications. In traceability systems, WSN can be used in the physical layer sensing and sending information about the conditions of products/units during the whole supply chain. Network setups without fixed infrastructure which is suitable for not reachable places and can be accessed by using a centralized monitor.

- Block chain Technology

A block chain technology is emerging technology which is a database stored in a multiple locations that can maintain increasing records (blocks) which are timestamped and linked to previous records (blocks) in a way which cannot be undone. It records the data added and updated to entire network and cannot be changed. Elements in the supply chain can track the materials, determine its locations, elements who handled it and who transported it. Having reliable data from whole supply chain could help in the event of product recall or non compliance of specifications.

Challenges in food traceability systems for India

- Cost:

Costs related to traceability includes cost of installation, operation of technology/systems for traceability, changes, updating and training costs etc. This costs can be significantly high for small enterprises which are major part of supply chain in food processing in India.

2.Linkage of information.

Majorly there is lack of structured linkage of information in various element of supply chain. Traceability is considered one step up and one step down in major food processing industries in India.

3.Competence and implementation:

Food Supply chains in countries like India consists majorly of small enterprises which are lacking the competent personnel to implement traceability systems effectively. Moreover for such enterprises providing proper and regular trainings related to documentation and system of traceability can be an ongoing challenge.

4.Data handling and analysis:

Often a smaller companies in supply chain where majorly manual data recording and handling is carried out ensuring proper handling of data. its analysis and security of information related to traceability is an ongoing issue.

5.Linking of traceability with food safety control measures:

Food traceability systems many a times are just limited to the systems which are used for tracking food products by lots or by units. However interpretation of this tracking data is not used while defining food safety control measures and as an input for continual improvement in FSMS (Food Safety Management System).

6.Multiple linkage and complex supply chains:

Indian food supply chain is characterized by multiple smaller linkages and having more complexity in supply chains. This scenario is challenging when thinking from the perspective of data collection, storage, handling and communication of information about the products throughout the supply chains.

7.Transparency and data security:

Transparency and data security related to product throughout supply chain is yet another challenge. Lack of transparency in information and tempering of data has been a problem specially for small enterprises. When it comes to an effective traceability system, the time taken for processing and retrieval of data has been an old issue. Data is often available but it takes considerably high time to process and retrieve it which is not good in case of emergencies like the case of food recalls.

8.Consumer requirements.

With rapid shift in consumer preferences, they demand rapid access to relevant and reliable information about the products. Due to availability of many sources of information like social media and internet, the consumers confidence has become fragile. Thus fulfilling this important requirements has been a challenging issue for food industries with respective traceability.

Conclusion:

For Indian food processing industries traceability system have some strength as well as challenges. So analyzing the challenges with respect to Indian scenario and implementation of suitable technology for traceability will not only improve the system but also become valuable input for linking it with food safety control measures. Thus traceability will become an integral part of continual improvement for food safety in food industries.

Compiled & Shared by- This paper is a compilation of groupwork provided by the

Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.

Secure Food Safety and Quality through Traceability System in India

Secure Food Safety and Quality through Traceability System

TRACEABILITY OF ANIMAL-DERIVED FOODS: A CRUCIAL ELEMENT FOR FOOD SAFETY