DISPOSAL & UTILIZATION OF DAIRY FARM WASTE

Dr.Mukesh Sharma, Dairy consultant

Environmental friendly disposal and utilization of animal manure is a significant challenge to the livestock industry. Animal waste contains many beneficial constituents that if recycled effectively, can be used as fertilizer for crops, fodder for animals and to produce energy. Animal manure is rich in nitrogen, phosphorus and potassium. In addition to providing supplemental nutrients for crop growth, manure has several beneficial effects on soil properties. Application of organic waste decreases the bulk density of the soil by increasing both the organic fraction of the soil and the stability of aggregates. Organic wastes also improves water filtration rate, water holding capacity and the hydraulic conductivity of the soil. All these properties of animal waste will be available only if they are carefully managed. If not they might cause detrimental effects on the environment. The most common environment concern with animal wastes is that it affects the atmospheric air with offensive odors, release of large quantities of CO2 and ammonia which might contribute to acid rain and the green house effect. It could also pollute water sources and be instrumental in spreading infectious diseases. If the disposal of water is not properly planned it might create social tension owing to the release of odours and contamination of water sources. Proper disposal and returning of nutrients back in the soil without pollution and spreading of diseases/pathogens, is required for efficient utilization of wastes on large farms.

Converting animal waste into energy can be a triple-hitter:

It not only helps reduce waste going to landfills or from being released as gas into the atmosphere, but saves energy and money.

Two types of animal waste are produced:

(i) Solid waste (dung): About ninety percent of manure is currently handled as a solid (e.g., in pastures or stacks on dry lots) but this portion produces only about twenty percent of total methane emissions from manure.

(ii) Slurry or liquid waste: Liquid manure management systems such as lagoons, ponds, tanks, or pits, handle a much smaller portion of total manure but comprise 80 percent of total methane emissions from manure. Liquid management is the more cost-effective option for manure management at large farms.

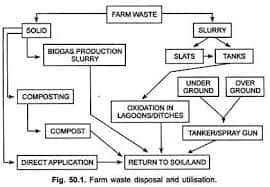

Different methods for disposing solid waste and slurry are used. Handling and utilization of slurry is more difficult. Various methods for the disposal of these wastes along with its efficient utilization are shown in Fig. 1.

Solid manure (cow dung) contains:

Moisture-77 %

Organic matter-20

Nitrogen-.32

Phosphorus-.14

Potassium-.30

Calcium-.40

Utilization of these nutrients by proper technique is highly desirable for efficient utilization of the animal wastes.

Various techniques used are:

1. Composting.

2. Biogas production (anaerobic fermentation).

3. Aerobic oxidation in ditches/Lagoons/lakes.

4. Direct application in field.

5. Use as fish feed in fish ponds.

6. For growing algae (diluted slurry).

7. Other techniques (less popular) recycling as filler in animal feed (i.e. poultry waste in cattle

feed, etc.).

Out of the above mentioned techniques most commonly employed are: —–

(i) Composting

(ii) Biogas production (anaerobic fermentation)

(iii) Direct application or application of slurry afer aerobic oxidation.

Disposal of Manure: ——

Frequency of Removal of Manure: Twice daily

Solid Manure: ——-

By means of wheel barrow and shovel, disposed into a pit for decomposition. Such manure will return 75 per cent of its fertilizing value to soil. Manure pits should be about 200 meters away in a place where no foul smell would pass through buildings. Te production of manure from each dairy cow is about 20 kg per day. The volumetric capacity of fresh manure is 700 to 900 kg/cu.m described by R.G. Linton.

Collection of Manure: ———–

Construction of manure pits depends upon the management practice followed in a farm. Te first method may be in which manure along with other waste is flushed together and in the second method the solid and liquid wastes are separated and used as manure.

The first method can be adopted in places where there is plenty of water to be forced and also in buffalo farms where the dung voided is watery in consistency. In these types of Animal sheds a U-shaped gutter or drain should be located longitudinally to the long axis of the shed. Outside the shed the liquid manure from each shed can be connected to a main shed preferably a closed one. The main drain leads the liquid water to a liquid storage tank from where it can be pumped to agricultural lands for manuring. In the latter method where solid and liquid manure are separated, a special pit has to be constructed to allow the solid waste to get decomposed. Te pit should be far away from water sources, animal and human habitations to avoid fly menace and spread of diseases. While planning for constructing a pit due attention should be given to the labor required in transporting and the mode by which the manure will be shifted to the pit.

Composting: ————–

In composting pile of solid waste is collected in pit 1.5 m deep and 3×4 meter dimension or large as per requirement (3 cubic meter/adult animal units) as per one design (Allnutt design described by R.G. Linton). This design has two pits with walls on all three sides covered on top with temporary roof to prevent desiccation, and alternative filing and emptying has been suggested.

The front side should have a gutter which should be filled with cresol and water to control fly breeding and the front side should have a vertical sliding shutter to prevent debris falling into the gutter. Te manure should be dumped and well packed in each compartment separately. While one is filled and packed, fermentation and decomposition occurs in the other which was filled earlier.The manure should be turned periodically to ensure uniform decomposition; this also enhances the destruction of larvae of parasites that are normally present in the dung.

During composting frequent mixing of waste is required. Te manure from other livestock

farms like sheep, goat, pig and poultry can be decomposed in the similar manner. After piling within 24 hours temperature rises to 50°C and within 3-8 days it reaches to 70°C. Tereafer it falls to 50°C. C: N ratio and moisture are important in this process.

Vermicompost: A Bonus for Livestock Farmer ——

Vermicompost is organic manure produced from the cast of earth worms especially Eisenia, Eudrillus, Perionyx, Dolvin species from agriculture and livestock waste. It is rich in N, P and K with several micronutrients, enzymes (proteases, amylases, lipase, cellulose and chitinase), plant growth hormones (auxins, cytokinins and gibberellins) and some nitrogen fixing bacteria (Pseudomonas, Actinomycetes, etc.) which enrich the nutritive value of vermicompost. Tough vermicompost is not comparable with chemical fertilizer but its application in soil improve soil structure, texture, water holding capacity, facilitates aeration and prevents soil erosion, thereby healthy, non toxic and tasty food can be produced from soil without any hazardous effect on health of human beings and animals.

The method of preparation is very simple and cost effective, which can be easily adopted by rural farmers for their benefit. Further, vermicomposting, as a technique, can effectively handle the huge amount of waste from agricultural and livestock source. This will undoubtedly add to prosperity of rural people by providing a healthy, wealthy and worthy environment.

Biogas Production: (Anaerobic fermentation) Tis is one of the best methods for waste disposal and utilization and extensively exploited in Japan and China.In this process organic matter is converted into volatile fatty acids which is in turn by the action of anaerobic bacteria (methanigenic bacteria) is converted to CH4 and CO2. Te slurry is valuable product for using in fields. Biogas is captured and burned to power the farm and/or generate electricity to be sold back to the power supplier. Capturing and using the methane prevents its discharge to the atmosphere, where it has 21 times more global warming potential than CO2.

Aerobic Oxidation: ———

Slurry can be disposed by keeping it in shallow ditches, lagoon, and lakes. BOD (Biological

oxygen demand) per acre is generally 20 for proper oxidation. Large areas are required and periodically solid sludge has to be removed. Upper water is used for irrigation after mixing with fresh water or directly also.

In a Liquid Form by Means of Lagoon: ——————

Lagoon is a body of water like a small pond where in liquid manure is discharged and digested by bacterial action. In this method fertility value of manure is wasted but helps in saving of equipment and labor which may compensate the loss. Pens are scraped and washed daily with water under pressure 75 Ibs./sq” inch and 500 gallons water per hour. Tis is run into lagoon which should hold at least one week accumulation of manure @ 20 kg/cow/day.

Bacterial Action in Lagoon: —————–

(i) Aerobic:

By aerobic bacteria in the presence of air/oxygen.

(ii) Anaerobic:

By green algae which use carbon dioxide, nitrate and other nutrients and in turn gives off oxygen for aerobic bacteria for oxidizing waste materials. Anaerobic bacteria also take over to decompose the waste materials which may produce undesirable odor too.

Water in Lagoon. Should be kept filled with water. Depth of Lagoon. Approximately two meters. Size of Lagoon. @ 6.5 m2/cow.

Location. 200 meters away from sties and prevent direction of prevailing winds.

Precautions: —————

(i) Provide safety fence around lagoon to make dog and child proof.

(ii) Make the bottom leveled and impervious.

(iii) Clean the lagoon once in 5 to 8 years or when necessary to remove accumulated sludge if filled up to depth of one meter.

Direct Application of Waste in the Farm Land: When large farm land not in productive use is available then direct application of solid waste by spreading or slurry by sprawling can be carried but this method is not an efficient method of utilization of farm waste due to loss of nutrients, problem of pathogens and sometimes causing toxicities to the plant grown on this type of land.

Conclusion:

In India as most animals are reared in close association with human dwellings, due care should be taken to ensure for hygienic maintenance of cattle shed. It is on public health interest that the manure should be promptly disposed and utilized in a proper way to conserve the manurial quality and also to prevent spread of diseases through insect vectors. The main principles of effective waste management of effluent are: effective recycling and reuse of effluent where feasible disposal, where its use is not practicable, in a manner that will not cause adverse short or long term environmental impact. Te development and implementation of a whole farm plan is a fundamental consideration for sustainable management of dairy shed effluent.

“Guidelines for Environmental Management of Dairy Farms and Gaushalas”

https://cpcb.nic.in/openpdffile.php?id=TGF0ZXN0RmlsZS8yOTlfMTU5NDY0MjQ4Nl9tZWRpYXBob3RvNTU4MS5wZGY=

Reference:On request.