Food Safety through Eggs

Introduction

Eggs are a staple food consumed worldwide, valued for their versatility, nutritional richness, and affordability. However, ensuring food safety through eggs is paramount to prevent foodborne illnesses and maintain public health. In the world of food production, ensuring food safety is paramount. Eggs, a versatile ingredient used in various culinary applications, can pose a significant risk when not handled properly.

Eggs are a nutritional powerhouse. They provide the body with 13 vitamins and minerals, high-quality protein, and important antioxidants. Eggs are also tasty, convenient, and good value for money, making them an excellent inclusion in a well-balanced diet. Eggs are accepted by all communities without restriction to any religion and are consumed globally by children, adults, and old people. Food safety is important with eggs as it can cause health risks if eggs are not handled, stored, and prepared safely. Some eggs may be contaminated with bacteria, which can cause serious food poisoning in susceptible populations. Educational programme of the public about the health hazards due to the consumption of raw eggs is required.

Spoilage of egg

The egg is very perishable and the quality can be severely reduced during the time of storage due to chemical changes or microbial spoilage and non-microbial spoilage. The changes occurring in the eggs are affected by the environmental conditions, temperature, moisture, the material used for packaging and storage time. Their high water content (74%) and high nutrient content make them susceptible to microbial spoilage.

- Contamination of eggs

Freshly laid egg is sterile but the egg shell soon becomes contaminated by fecal matter of hen by nest, by washing water, by handling, and by other material in which it is stored. A total number of micro organisms per shell of hen’s egg have been reported to range from 102-107 with average of 105. Salmonella spp. may be found on shell or inside egg.

- Non-microbial spoilage of eggs

These include loss of moisture and hence loss of weight during long-term storage. Change in the physical state of egg contents also occurs during long-term storage. They include thinning of egg white and breaking of yolk membrane. As the yolk membrane weakens and break, yolk becomes flat and homogenously mixed in egg white.

- Microbial spoilage of eggs

In order to cause spoilage of shell of egg, microorganisms must contaminate the shell, penetrate through the pores in shell and inner membrane, reach the eggwhite and yolk and grow there. Some microorganisms cannot grow in egg white but can grow rapidly in egg yolk. Change in storage temperature facilitates penetration of organism through shell and hence facilitates microbial spoilage.

- Bacterial spoilage of egg

Bacteria are more common spoilage organism than mold. Bacteria cause rots in egg. When bacteria grow within the egg, they decompose the content and form byproducts. This result in the development of characteristic odor, appearance or color.

Green rot

It is caused by Pseudomonas fluorescence. Green egg white shows fluorescence when exposed to UV light. In later stage of spoilage, egg yolk disintegrates and masks green color of egg white. Odor is lacking or fruity or sweetish.

Colorless rot

It may be caused by Pseudomonas, Acetobacter, Acinatobacter, and coliform. In the later stage of spoilage, egg yolk disintegrates or at least has incrustations.

Black rot

It is caused by Proteus and sometimes Pseudomonas and aeromonas. Egg yolk blackens and then breakdown to give the whole egg content muddy brown color. Odor is putrified due to H2S.

Pink rot

It is caused by Pseudomonas usually at the later stage of green rot. They are similar to colorless rot except that pink coloration occurs in yolk and white.

Red rot

It is caused by Serrotia marcesceus. These eggs are distinguished by a rod dissociation of egg white and the surface of the yolk in ammonical i.e. putrified odor.

Custard rot

In this rot, the yolk is incrusted with custard-like material and occasionally has green to olive pigment. The albumin becomes thin with orange coloration. This type of spoilage is caused by Citrobacter and Proteus vulgaris.

- Fungal spoilage of egg

Fungal spoilage goes through following stages.

Pin spot molding

In this case, small compact colonies of mold appear on the shell and usually just inside the shell. The color of pin spots varies with the type of mold. For example, Cladosporium give black spot and Sporotrichum give pink spot.

Superficial fungal spoilage

This occurs if eggs are stored in atmosphere of high humidity. In this case, molds grow on shell in the form of whiskers.

Fungal rotting:

It is the final stage of spoilage by mold. In this case, mycelium of the mold grows through the pores and cracks in the shell. Jellying of egg white may occur and colored spots may be produced. Hypha of mold grows through the yolk membrane and ruptures it, so that yolk mixes with the white.

Molds causing spoilage of egg include Penicillium, Sporotrichum, Mucor, Botrytis, Alternaria, Thamnidium, etc.

Preservation of eggs from spoilage

Eggs have several ways of protecting themselves from microbial spoilage. Shell and underlying membrane serve as the first line of defense to prevent the entry of microorganisms. In addition to the physical barrier, egg albumin is not a suitable growth medium and discourages the growth of many microorganisms. Characteristics of egg albumin that discourage microbial growth include pH of 9-10, low level of simple nitrogenous compound, apoprotein that binds riboflavin, avidin that binds biotin, ovotransferrin that chelate iron, and lysozyme that hydrolyze peptidoglycan of bacteria. Despite physical barriers and other anti-microbial factors, many microorganisms can invade and cause spoilage of eggs. Therefore, the following methods are employed for its preservation.

Asepsis

Great care should be taken to reduce contamination by fecal matter by dust and nest. When eggs are broken for freezing or drying, a spoiled egg should be discarded and contamination from equipment can be reduced by sanitizing it.

Removal of microorganism

Various methods can be employed to remove dirt and faecal matter from egg shell. Dry cleaning by sandblasting removes dirt and bloom. Washing with warm water removes dirt, bloom, and apart of microorganisms but encourages penetration of bacteria into egg through pores in shell. Use of disinfectant in washing water reduces the number of microorganisms.

Preservation by use of heat

Heat treatment suggested include heating whole egg in oil for 10 minutes at 600C or in water at 54.4oC for 80 min, Immersion of egg in boiling water for few second, immersion of egg in hot detergent, Sanitizer solution at 43.3oC to 54.4oC. Pasteurization is required for most egg products. Because of the heat coagulability of egg, stabilization is required before pasteurization. This includes the addition of aluminum salt and adjustment of pH.

Preservation by low temperature

Chilling

Eggs are commercially stored for six months or longer, at a temperature of -1.7oC to – 0.55oC and relative humidity of 70-80%. If the temperature is greater than -1.67, there is more rapid penetration of microorganisms and growth into egg and more physical and chemical changes. Special treatment like impregnation of egg shell with colorless and odorless mineral oil keeps out moisture slows desiccation and air penetration during chilling.

Freezing

Eggs are first washed with 200-500ppm chloride solution and broken. Egg yolk and egg white are separated and they are frozen separately at -17.8oC to -20.5oC.

Preservation by drying

Eggs are first washed with chloride solution, broken and then yolk and white are separated. A liquid egg is then dried by drum drying or spray drying method. Glucose should be removed from egg before drying because it causes the browning of an egg.

Preservation by chemical preservative

Preservatives may be used on shells of egg in the atmosphere around them and on containers for egg. Waxing and oiling of shell keep the shell dry, reduce the penetration of oxygen into the egg and reduce the passage of carbon dioxide and moisture out. Immersion of whole egg in the solution of sodium silicate is also a good preservative. Use of CO2 in ozone in the storage atmosphere improves the quality of egg.

Food safety

Contamination of eggs poses a high risk to food safety. Use of good hygiene practices (GHP) can maintain the high quality and safety of eggs. The staff handling eggs should have knowledge and skills in food safety and hygiene. Eating of raw egg is not recommended. Do not use raw or soft-boiled eggs in food preparation that will not be heat treated or cooked. Keep the egg shell dry to prevent penetration of microbes. Eggs must be properly dried before packing. Maintain the egg quality by using good packing, storage, and transport methods. Eggs should be kept at a cool temperature following packing and throughout transportation. Do not send broken egg, or soiled egg to the market for sale. It is important to discard the eggs that are broken and leaking. Homemade foods containing raw or lightly cooked eggs are often linked to food poisoning. Hence, thorough cooking is very important to assure the safety of eggs. It is advised to use pasteurized eggs or egg products. Do not reheat boiled eggs in the microwave.

Boiled egg, fried egg, backed egg, poached egg, boiled egg, and scrambled egg should be cooked until both the white and the yolk are firm. The ideal conditions for the storage of eggs are about –10°C and between 75-80% relative humidity. There is a risk of mould spoilage when relative humidity is too high. Washing of hands, utensils, equipment, and work surfaces with hot, soapy water before and after they come in contact with raw eggs and raw egg containing foods is highly imperative. Egg can become contaminated from various sources, hence, it is important to maintain sanitary conditions. The consumption of contaminated egg can cause salmonellosis in humans. Outbreaks of salmonellosis involving eggs or egg containing foods result due to inadequate refrigeration, improper handling, and insufficient cooking. It is imperative to maintain high quality and safety by using good hygiene, cooking, refrigeration, and handling practices.

Maintaining the Freshness of Eggs

- Eggs maintain their freshness for up to 10 – 12 days, after they are laid, at room temperature of about (28.2°C), but the shelf life will be shorter at higher temperatures. The important factor in maintaining egg freshness is mainly temperature while humidity also affects the same to some extent. Storing the eggs, in refrigerator, in designated shelves or egg cases is the best way to maintain their freshness.

- To maintain egg freshness and performance, buy the eggs from stores that keep the eggs at cooler temperatures [air-conditioned stores or supermarkets) or stores that keep the eggs in well ventilated covered places and maintain ambient temperature.

- In most cases, eggs that are clean, free of visible defects or cracks and bought from a place that stores eggs under cooler temperatures will remain fresh for 4 to 5 weeks from the time they are laid provided that the eggs are stored in their carton in refrigerators. Beyond this period, the egg quality starts to deteriorate.

- Consumers should strictly avoid handling eggs roughly and leaving them in hot vehicles or places where temperatures are very high. Refrigerate the eggs once you reach home.

- Do not use dirty or cracked eggs. Cracked egg shells are a perfect foil for bacterial infections and the dirty eggs may also contaminate other food stuffs. Dirty eggs may be contaminated but may not still smell bad. Avoid washing dirty eggs, as they would become more porous when wet, thus makmg an easy entry for bacteria inside eggs.

- If an egg is cracked or too dirty, dispose it off.

- Always wash your hands thoroughly with soap and water after handling eggs.

- Feed quality is also an important factor affecting the overall quality of eggs. Eggs produced by farmers who used castor seed cakes as source of protein were reported to have rubbery textures. Therefore, poultry feed used in poultry farms should be approved by concerned regulatory bodies like BIS, etc.

Testing Eggs for Freshness

- Fresh egg, when held against a very bright light in a dark room, will display a small air gap usually at the broader (blunt) end of the egg. As the egg ages, the air cell expands in volume. Upon hard boiling a fresh egg, you can clearly see the indentation left behind at the top of the egg once the shell is peeled off.

- In case of fresh eggs, the yolk normally stays in the centre and is not very mobile because of the chalaza (the strings of tissue) that hold it in place. These strings break down as the egg ages (during storage or transportation]. When hard boiled eggs are cut length wise, one can see that the yolk has moved off the centre.

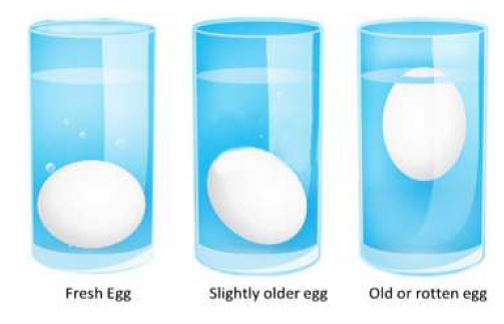

- A quick test to check the freshness of an egg is to immerse it in a mug or basin of water. Fresh eggs would remain at the bottom width wise, older eggs would remain at the bottom on one end while the stale/rotten ones would float because of the larger air cell. It is to be noted that sometimes weak shell and fine cracks can also cause the egg to float.

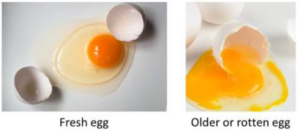

- When broken out of the shell, good quality, fresh eggs display certain characteristics as mentioned below:

The yolk (yellow portion) would be rounded, small and stands high in a thick and gel like egg white. The gel like mass of egg white does not spread over a wide area but tends to stay compact. As the egg ages (with storage and temperature associated with storage), the egg white becomes thin and runny and finally egg yolk and white dissolve into each other in older or rotten eggs (or the alleged plastic/fake eggs). The older eggs may also develop rotten odour and would have lost the typical egg odour.

With the aging of egg and the white becoming thinner, one can clearly notice that it will take a longer time to whip into foam, and when whipped the foam is less stable or collapses faster. However, it is also important to note that very fresh eggs also do not foam well and take longer time; but, once beaten the foam is very stable as compared to older eggs. The maximum and better foam volume/stability can be obtained from three or four day old eggs.

If not stored properly, eggs become plastic-Iike

The way eggs are stored is as important as for how long they are stored. Eggs can lose as much quality in one day at outside high temperature as in 4- to 5 days in the refrigerator. Eggs kept at room temperature can maintain their freshness for up to 10 – 12 days after being laid, but the shelf – life reduces with increase in storage temperatures.

The following changes happen in an egg as a function of storage. These changes in egg quality as the egg ages are summarised in the figure below. To slow down these changes, freshly laid eggs should be put in cold storage, and/ or the shells can be covered with a thin layer of an approved oil, particularly over the air cells.

While transporting and storing eggs undergo different temperatures. Due to this, the air cell in the egg increases in volume, loses water content (through more than 20000 pores in the egg shell) from the yolk and albumen due to evaporation through (more than 20000 pores) the shell. The chalaza, a funnel shaped proteinaceous matter connecting the yolk and albumen starts disappearing and finally the egg loses its weight (a normal fresh egg weighs around 50-65 g, while older or rotting eggs would lose about 15-20 g of their weight). The increase in air cell volume can be easily detected by piercing the broader end of the egg with a pin. A normal (fresh)egg does not give away easily while an older egg simply gives in due to increased air cell.

As a consequence of water loss in eggs, the egg white and yolk portions shrink followed by mixing of these two portions. Both these portions dissolve into each other, and when such an egg is broken it does not give a separate egg yolk or white giving the impression of a fake (or plastic)egg. Further, the smell of mixed yolk will not have the typical odour one associates with a fresh egg. Moreover, the shell membrane in a normal (fresh) egg is slimy and appears smooth. With the loss of moisture this membrane becomes dry and has a paper like appearance and texture. This again creates the impression that the egg could be plastic or fake. One should note that the membrane of a fresh egg would take time to burn when held against a flame, while the membrane of the older (fake or plastic) egg would burn quickly due to its dryness; but, both would produce the same kind of ash withouta hint of smell that is normally associated with burning plastic.

Consumers can find out if the egg is genuine by simply dipping the shell pieces of suspected fake(or plastic) egg in strong acids (like 2N hydrochloric acid). Calcium carbonate, being the major component of egg shells, will dissolve the shells in the acid. Alternatively, egg or eggshells when placed in vinegar (~which has 3-4- percent of acetic acid) will dissolve the shells slowly but will start giving out bubbles (and sometimes make the eggshells float, in case of pieces). The membrane of such acid treated shells will have no adhesion to the shells but will almost have the texture of a paper or thin plastic.

For traders and retailers

- Source eggs from credible sources only.

- Traders and retailers can minimise the decline in egg quality by observing the following basic guidelines:

- Have adequate and cool holding places to store eggs (preferably refrigerated)

- Avoid storing eggs close to strong smelling food or food products

- Store or display eggs away from sunlight

- Strictly rotate the egg stocks on FiFo (First in First out) basis i.e. keep older stock in front of fresh stocks so that all eggs sold are as fresh as possible

- Avoid transporting eggs in hot vehicles or hotter temperatures

- Advise the consumers to store the eggs in cooler temperatures or refrigerators

- Immediately discard any cracked or dirty egg

- Do not sell dirty eggs to consumers

For regulatory staff and laboratories

- Sample condition: Egg samples collected for analysis should preferably be transported under cooler temperatures without subjecting them to higher temperatures. It is advisable to transport the eggs in cartons or egg cases if being sent for analysis.

- Screening and confirmation: Screen any suspected fake egg samples for true protein by Biuret’s/Lowry’s as well as Kjeldahl methods. Natural chicken eggs (whole egg), would generally have a protein content between 11.5 to 12.5 percent, lipid content of 11.5 – 12 percent and almost no carbohydrate (<0.5 percent, if any). Since egg is known to have the most desirable amino acid composition, next only to milk; amino acid composition will also help distinguish the normal eggs from allegedly fake eggs.

Key Takeaways

Consumers need to know that there are no available techniques to make an egg artificially.

The way eggs are stored is as important as for how long they are stored. Eggs can lose as much quality in one day at room temperature as in 4 to 5 days in the refrigerator.

Eggs kept at room temperature can maintain their freshness for up to 10 – 12 days after being laid, but the shelf-life reduces with increase in storage temperatures.

Consumers should store eggs in refrigerators in designated shelves or inside egg crates.

In most cases, eggs that are clean, free of edible defects or cracks and maintained under cooler temperatures will remain fresh for 4 to 5 weeks from the time they are laid.

Retailers /traders should source eggs from credible sources and store them in refrigerators.

Do not use dirty or cracked eggs. Cracked egg shells are a perfect foil for bacterial infections and the dirty eggs may also contaminate other food stuffs.

Appropriate temperature and relative humidity (RH) need to be maintained for storing eggs in the cold store, the lack of which can result in mixing up of the yolk and albumin.

Consumers can make use of this guidance note to check the freshness and quality of eggs easily as home with the help of simple tests.

Ensuring food safety through eggs requires a comprehensive approach encompassing all stages of production, handling, and consumption. By implementing rigorous hygiene practices, quality assurance measures, and regulatory oversight, stakeholders in the egg industry can minimize the risk of contamination and safeguard public health. Consumer education and awareness are also essential to promote safe handling and consumption practices at home. By working together, producers, regulators, and consumers can contribute to a safer and healthier food supply chain, ensuring that eggs continue to be enjoyed as a nutritious and safe food source for people around the world.

Compiled & Shared by- This paper is a compilation of groupwork provided by the Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request