VALUE ADDITION TO POULTRY EGGS (POST HARVEST TECHNOLOGY) IN INDIA- FUTURE PROSPECTS

Adding value to eggs is a good option for a farmer who wants to beat the low prices. Value added products include scrambled eggs, sandwich fillings, egg rolls, hard-boiled eggs, albumen flakes, pancake, egg patties, egg pizza, egg crepes, egg roll, egg strips, egg waffles, egg soufflé, egg cutlet, albumen rings, brined and pickled eggs. This is otherwise called as post-slaughter or post-oviposition value addition“, which is usually referred as “post harvest technology“. To process the eggs, one can boil, dip in mineral oil, spray, pasteurise, dehydrate or freeze. One of the main challenges poultry farmers have to deal with is the low egg prices. This sometimes drops to a level one gets loss due to high feed prices and cheap eggs import. Egg processing serves a rapidly increasing market worldwide

Indian Poultry Industry is one of the fast growing markets in poultry production accounting to 2.8 billion broiler and 68 billion egg production. Although poultry industry shows enormous growth, the poultry processing sector is still underdeveloped due to less demand for the ready to eat and cook products and less acceptability of processed poultry products. At present marketing of poultry products has many hurdles such as, unstable market, increased taxes on processed foods, competitive feed costs, high transportation charges, lack of cold chain facilities and non-compliance of food safety norms. However continuous research and development leads to the development of low cost and efficient poultry processing technologies and well established quality control norms. Poultry marketing system in India dominated by private traders and commission agents needs to be transformed into an organized system for uniform sharing of profits by all players in the industry.

Irrespective of massive breakthrough in production front, the processing sector is still in infantile stage and marketing sector is mostly in disorganized way (Singh 2012)Currently only 20 % of the chicken and 6% of the eggs are processed. Among the dressed chickens, 70 % are sold as dressed or chilled or frozen whole carcass, limiting remaining 30% to cut up parts and further processed products. On the other hand, in the industrialized countries, whole broiler sales recorded at 15%, cuts and boneless breast fillets 35%, further processed products 50%. Likewise 30% of the eggs produced are processed as pasteurized chilled-frozen liquid egg, dehydrated and ready to eat egg products. Right now, only dozen modern mechanized processing plants with capacity of 2000-4000 chicken per hour and three export oriented egg processing plants process the 4.5 million eggs per day (Singh 2012). Major constraints in our country for lack of processing is less preference for frozen chicken by the consumer, insufficient cold chain infrastructure facilities, lack of well organized marketing system, less domestic demand for value-added egg products, non-availability of adequate technology, fluctuating export trade, high import duty and strict sanitary and phytosanitory norms by importing countries. However, India with so many limitations now emerged as a leading exporter of shell eggs, frozen and dehydrated egg products and frozen broilers

Commercial Egg Products —–

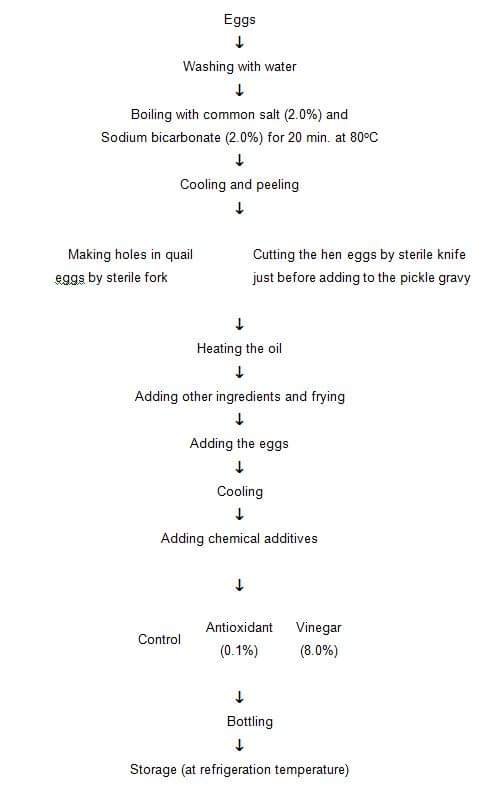

Egg products at USDA may be classified under following ways (a) Refrigerated (as liquid) e.g. Whole eggs, whites or yolks, sugared egg yolks, salted egg yolk, scrambled egg mix, extended shelf life whole eggs (b) Frozen: e.g. Whole egg, white or yolk, scrambled egg mix, salted whole egg, sugared egg yolk and whole egg mix (c) Dried: e.g. White egg or yolk solids, dried egg, whole egg (d) Specialty products: e.g. dried hard cooked, peeled egg, whole hard cooked peeled egg, egg yolk, long egg quiche mix, and ultra-pasteurized liquid egg products. Certain commercialized egg product preparations are as follows 1. Pickled eggs: A simple, cost-effective and efficient technology developed for ready to eat pickling of quail eggs/ chicken eggs for storage and marketing at ambient temperature. 2. Salted chicken eggs: Preparation of salted chicken eggs technology is so simple to be used by unskilled people. 3. Albumen rings: Albumen rings are egg snack food, prepared by cooking blended egg albumen in ring moulds and battering and breading the coagulated albumen prior to deep fat frying. 4. Egg roll: It is a nutritious, tasty and convenience egg product suitable for meals or as snack foods. 5. Egg crepe: Egg crepe is a thin, fat, circular product and may be filled with meat or vegetables and rolled or folded.

Advantage of Egg Products Marketing—

Encouraging the poultry Egg product marketing ensures steady flow of products to the consumer in an effective manner, thereby increasing the economic activity. It further maintains the steady price distribution for the sale of product in much profitable manner due to high returns. It also gives way to employment generation and income generation activity. Marketing of the poultry product can also enhance the nutritional security of the different target groups. Marketing of the poultry products make the poultry products available at the right time, right place in right quantity and at right price. However in India major problem in marketing is the lack of efficient and organized market network.

Production Cost —

In general the average variable cost of production is lowest in the south followed by west, east and north. The feed consumption rate (FCR) based market is generally higher in the north because of higher market weight, higher mortality rate due to extremes of hot and cold temperature. Projected global egg and meat production during 2020 are 77 million tons and 123 million tons to cater to the demands of 8 million of the human population.

Channels of marketing-—-

Currently more than 75% of the poultry products are reaching the consumers through various channels of distribution leading the consumers to pay more and producers to get fewer margins. Besides, major share of the profit at present goes to the middlemen. At present poultry products are marketed in the following four marketing networks. 1. Producer-Consumer 2. Producer- Wholesaler- Retailer- Consumer 3. Producer- Collector- Assembly merchant- Consumer 4. Producer- Retailer Channel 2 may account to marketing of major portion of eggs to the consumers. Channel 4 is responsible for getting 12-15% of the total profit to the retailers. However in channel 2 a middleman gets 22% of the profit. National Egg Coordination Committee owned by private sector organization and National Agricultural Cooperative Marketing Federation governed by Government of India to some extent streamline the marketing of major poultry products. Major Meat consumption pattern in India are towards fish, mutton, bovine and goat meat as given in the figure 1 below:

Prospects of Poultry Marketing——

Considering the fast growth of the poultry industry in the past further growth and marketing of the poultry industry are limited due to the following factors • Demand for poultry meat is highly price sensitive among low and middle income groups

• Major limitation is logistics and distribution network within India mostly due to limited demands for frozen products, high cost of transport infrastructure, unreliable cold chain facilities and the quality of the products produced. • Vertical integration encourages higher production, better marketing efficiency with reduced consumer prices • In India marketing efficiency is important than the production efficiency • Competitive feed price results in competitive meat and egg production • Seasonal variation due to religious practices

Foreign Direct Investment (FDI)———-

Foreign direct investment is yet to take a forward movement in India’s poultry sector. However, FDI has the potential to invest in important input activities like breeding, medicine, feed, equipment, vertical integration and processing. Still major limitation for the FDI in India is due to unstable market, poor power, transport facilities and high taxes on processed food. Expansion of the poultry industry marketing mainly depends on the transition from live bird market to a chilled or frozen product model. Live bird market restricts the exploitation of the regional imbalance, use of storage facilities for domestic product movement and export promotion to stabilize the demand and supply. In addition, movement of live birds increases the cost of production due to transport, shrinkage and mortality. Altogether Indian poultry market is regional rather than national limiting low cost producer to market the products in higher cost region. Preference for the live bird is mostly due to reliability on the quality of the fresh poultry meat that is slaughtered in their presence. Foreign direct investment is now most common in the pharmaceuticals as most of the companies in India are multi-national corporations. In respect of feed production, most of them are India feed companies except Java Pelletizing Factory Comfeed India Pvt. ltd. (JAPFA) from Indonesia and Charoen Pokphand (CP) from Thailand. Major advantage for trading in India by FDI is attributed to thirty percent local outsources from small and medium size industries, backward infrastructures investment to strengthen the supply chain and other obligations. Consequent to entry of Foreign Direct Investment (FDI), there will be following three major changes. 1. Investment by multinational retailers in start of art of technology 2. Participation of more international trade 3. Possibilities of larger portion of market by Multinational Corporation (MNC) due to monopsony.

Private Players in Poultry Industry—–

The major private industries involved in the poultry processing, further processing operations and marketing poultry products are Venkateshwara Hatcheries Pvt. ltd.,Suguna Poultry farm ltd., CP (Charoen Pokphand India), KFC (Kentucky Fried Chicken), SRM agro foods, McDonald’s and Arthur’s food company pvt. ltd.

Prospects of Future Poultry Egg Products Marketing-——-

Almost two-thirds of the global egg production has occurred in developing regions of Asia. Egg processing is mainly dominated by industrialized countries where 35% of table eggs are converted into processed products. Table eggs and liquid egg products are traded within European and Asian countries. Dehydrated egg products are better traded in large amounts because of its long shelf- life and low transport cost. India has also ventured in this on a modest scale. India’s combined egg processing plants capacity is at 12000 metric tons per year. Major areas of research in egg processing in India is on design and fabrication of a low cost, batch -type immersion egg washing machine and development of egg washing powder. Recent advancements in egg processing technology include improved egg spray washers and egg coating oil for preservation which maintains the quality of eggs up to 4 weeks at ambient temperature (26°C). Further processes have been developed to control gelatin in frozen yolk/whole egg liquid by 0.02% pepsin, 0.5% trypsin, 5 to 10% common salt or cane sugar or 5% glycerol in the egg magma prior to freezing. Manufacturing technologies for a number of valueadded products live as whole egg powder, yolk granules, albumen flakes, albumen rings waffles, canned curried eggs, scrambled egg, omelet premixes, egg patties, egg- chicken meat patties, egg pizzas, egg roll, sponge and pancakes, albumen yolk cubes, mayonnaise, egg- enriched biscuits, breads and egg milk beverages have been adopted. Ultra-pasteurization-cum-aseptic packaging techniques are also available to extend the refrigerated shelf-life of liquid egg up to 4 and 24 weeks at 10°C and 4°C respectively for marketing in non-frozen form. Presently another advanced method of vacuum evaporation of liquid whole egg followed by quick freezing to produce frozen egg pellets has also been developed.

By-Products-———–

Poultry slaughter waste, hatchery waste and egg shell waste are being generated to the tune of three lakh tons, 0.6 lakh tons and 0.34 lakh tons respectively in India. Conventional methods are being employed to convert the egg shell into egg shell meal by centrifugation to recover residual albumin subsequently with autoclaving, oven drying and grinding into coarse or fine powder. Extrusion technology has also been attempted to utilize the poultry by-products into extruded pet food. Unorganized disposal of poultry offal could be easily transported using 2% formic acid or 4 % acetic acid for the period of 10 days at 26± 2°C. Projected global egg production and meat production during 2020 are 77 million tons and 123 million.

Weakness-—

Need for Emerging Technologies to Encourage Marketing Marketing of any products depend upon its shelf life , maintenance of nutrient content, easy transport, ecofriendly packing material, easy availability, aesthetic acceptance of the consumers. Accordingly there is a necessity to concentrate on the research and development wing to come out with newer technologies on the following lines. Design of mini poultry processing units Shelf-life extension of poultry products by application of hurdle technology and biotechnology means Developing newer techniques for tenderization of meats Efficient processing techniques for extraction of lysozyme, avidin, lecithin and other biomolecules from eggs Ultra-pasteurization cum aseptic packaging technology for liquid egg

Uniform processing technology for traditional poultry products Improved packaging techniques like vacuum, MAB, CAP, retort and aseptic Development of quick and sensitive methods for detection of pathogens and hazardous feed residues Application of bio- processing techniques for efficient disposal of poultry products User-friendly transport system as per the food engineering norms

Opportunities——–

Rapid urbanization, industrialization, rising disposable income, changing food habits towards processed products and higher middle income group are major positive factors to boost up processed food markets. Strict adaptation of GMP and HACCP system can give major possible export of frozen broilers in the European Union, Japan and Russia as per Rabo bank report 2008. Major limitation factor for export of poultry products is attributed to non-compliance of quality norms prescribed by the codex alimentarius. Following are the major elements need to be given due attention to encourage the export of poultry products Application of modern processing techniques Provision of logistic support Production of quality products fit for export Policy changes in the government level Developing the appropriate packaging technology Effective R & D work to increase the shelf life of the products Harmonization of quality control norms Single window approach for export Creation of database Well trained techno graphs and skilled human resources NABL accredited laboratories for certification of food products Cost effective mini poultry processing units

Threats—–

Marketing System At present poultry marketing is dictated by the private traders and commission agents present in various cities and towns. Most of the trading activity of the poultry meat and egg is in the disadvantageous position to the farmers giving lesser margins of profit than the traders’ profit margin. Right now, organized marketing network need to encourage positive trend for uniform profits to all the players in the poultry industry.

Value added egg products——

Pickled eggs: A simple, cost-effective and efficient technology developed for pickling of quail eggs for upto 4 months of storage and marketing at ambient temperature in ready-to-eat form.

Salted Chicken Eggs: A simple technique for preparation of intact salted chicken shell eggs has been developed which obviates the need for using salt prior to serving boiled eggs and hence a convenient product for egg vendors.

Albumen Rings: Albumen rings are egg snack food, prepared by cooking blended egg albumen in ring molds, battering and breading the coagulated albumen prior to deep fat frying. It can be popularized as egg snacks at growing fast food outlets.

Egg Roll: It is a nutritious, tasty and convenient egg product suitable for meals or as snack foods. This product offers a potential market at growing fast food outlets. Egg roll filled with 80% scrambled egg and 20% chicken meat mixture (shallow pan fried) was rated best in flavour, texture and overall acceptability. Egg roll had a refrigerated shelf-life of 8 days in vacuum and 6 days in aerobic pack.

Egg crepe: Egg crepe is a thin, fat, circular product and may be filled with meat or vegetables and rolled or folded. It is an egg-rich product and can be popularized as a convenient egg item at growing fast food outlets and at homes. Crepes has a shelf-life of 22 days in vacuum and 20 days in aerobic packaging at refrigeration (4 ± 1°C) and for 60 days at freezing (-18 ± 1°C) temperature in both vacuum and aerobic packaging.

Egg Waffles: Egg Waffle is a nutritious, light, crispy and versatile snack food for the breakfast. This product offers a potential market at growing fast food outlets. Egg Waffles prepared from 65% liquid whole egg with 10% wheat flour and 5% granulated wheat are most acceptable and has an ambient shelf-life of 4 days in vacuum and 3 days in air packs, while at refrigeration temperature, it can keep well for 10 days in vacuum and 6 days in air packs with satisfactory microbiological quality.

Post-Harvest Management and Value Addition

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.