HOW TO MAKE LAYER FEED FOR A LONGER PRODUCTION CYCLE AND HIGH PERFORMANCE

Higher laying rates, better persistency and longer production cycles are observed over time . This trend will continue as breeding companies, egg producers, and animal feed companies collaborate more and more to maximize animal performance, feed efficiency and animal welfare. Genetic progress and longer production cycles have consequences for nutrition.When layers are kept in production for 100 weeks instead of 60 or 80 weeks, egg output and associated export of nutrients is much higher. Egg mass, and therefore also yolk output, increase enormously, as is the case with egg shell and the calcium in it. High performing birds need a perfect feeding strategy to maintain the desired performance levels. This article looks at the factors that should be taken into account when designing a perfect feeding strategy. In addition, make sure you are familiar with the genetic potential of your birds and their breed specific nutritional requirements.

Nutrient intake

The actual nutrient intake in gram nutrient per hen per day is a result of the diet composition (feed formulation) and the feed intake level (feed consumption). The actual nutrient intake should match the nutrient requirements in all stages of birds’ development: growth, growth combined with (start of) production, only production. Besides growth and/or production, nutrients are always needed for maintenance. Nutrient requirement is also influenced by production level of egg mass, which is a result of egg weight and deposition. In the period 18-35 weeks of age, birds are still growing and therefore need nutrients and energy for growth, next to their standard needs for maintenance. As birds also come into production in this period, nutrients and energy are needed for egg production as well. Unfortunately in the period 18-25 weeks, feed intake capacity is still limited and might not cover the nutritional and energy requirement which results in a deficiency. Other factors which can lead to a deficiency is when daily feed intake is low due to high environmental temperatures. In these situations an additional midnight feeding can be offered to the birds in order to increase daily feed intake. If daily feed intake is to low, also check water intake level. Too strong restriction on water intake or water with flavor deviation due to pollution can result in lower feed intake, which can result in lower egg weights and finally lower egg mass produced. A situation of low feed intake resulting in a nutrient and energy deficiency at start of lay, can have an impact on the whole production cycle by, for example, lower production in terms of lower laying rate and egg weights, increased mortality, and reduced egg shell quality. Therefore always check nutrient requirements with actual feed intake level, because: nutrient intake = diet composition x feed intake.

Amino acid requirement

Requirements for amino acids can be expressed in ideal amino acid profiles (defined as a percentage of lysine) or in mg amino acids per gram of egg produced. Actually, three different stages and corresponding ideal amino acid profiles can be distinguished: growth, growth combined with (start of) egg production, and egg production. Although all essential amino acids could be a limiting factor, lysine is the most commonly observed limiting factor for growth because development of muscle mass is at high level, while it is methionine during egg production. At the start of egg production, feed intake capacity is still limited and might not cover the nutritional requirements for amino acids which results in a deficiency.Therefore amino acid levels should be adjusted towards actual feed consumption observed and egg mass produced. Later on in the production cycle, requirements for e.g. digestible methionine reduce with approximately 12% from 60 weeks towards 90 weeks of age. However, birds within the same flock will differ in their production performance level and consequently show variety in their requirements for methionine. This stretches the approach that later on in the production cycle, after growth has been finished (approximately 30-35 weeks of age), amino acid levels should be determined based on daily egg mass produced (deposition and egg weight) and not on the age of the birds. Another important fact to take into account is that the ‘average laying rate in percentage’ does not match individual performances and it could be that two thirds of the flock performs above this average. If the average laying rate is used to estimate the daily amino acid requirements, this can lead to an underestimation of the actual requirements of most of the birds. Because of differences between birds in performance, nutritional requirements have to take into account flock uniformity by feeding and managing the weakest birds while allowing the best birds to produce at their genetic potential. This can be achieved by respecting a safety margin for the inclusion of digestible amino acids in a situation where uniformity is low. If levels of digestible amino acids are set above theoretical concentration (+5%) excellent results can be achieved. To conclude, provide enough amino acids (take daily egg mass and actual feed intake into account), keep flock uniformity in mind and provide amino acids above theoretical requirement for excellent results.

Energy requirements

Energy requirements are determined by maintenance (body weight, feathering, temperature regulation, and activity), egg production, and growth. As mentioned before, three stages of birds’ development during lay which influence the requirements are: growth, growth and production, only production. The energy consumption is determined by energy feed concentration, feed presentation, and feed distribution/management. There is a relation between feed consumption and metabolisable energy intake as layers adjust their feed consumption according to the energy concentration in the diet. However, this regulation mechanism is not perfect and a higher concentration of metabolisable energy (in Kcal/kg) leads to a higher energy intake (in Kcal/day/animal) even though the daily feed consumption (in gram per day) is reduced due to an increase in metabolisable energy concentration. As with other nutrients, energy intake is challenging in the period of start of lay where feed intake capacity is still low and requirements are high due to growth and start of production. Therefore, at onset of lay the priority is to reach adult body weight to obtain a good persistency in lay during the cycle. To achieve this, a feed high in metabolisable energy is needed, higher than the diets provided later on in the cycle. If birds still struggle with gaining enough body weight at start of lay, energy content could be increased by an additional 50-100Kcal/kg. After reaching the adult body weight and egg weights have reached a desirable level, energy levels can be lowered towards the end of the cycle. The objective in this feeding program of adult birds is to avoid birds getting fat. Prevention of fat birds by lowering energy levels and controlling energy intake can be achieved by increasing the fibre content in the diet towards, for example, 7%. When insoluble fibres, like oat hulls, are used especially in a coarse form, improvement of liveability can be expected. For a good energy management, frequent monitoring of feed intake and body weights is essential. Thus, control the birds’ energy balance by respecting the amount of energy needed for growth, performance and maintenance. Furthermore, lower energy levels towards the end of cycle and control feed consumption by adding insoluble fibres (like oat hulls) to the diet in order to be successful in a longer production cycle of 90-100 weeks.

Liver health

The liver is considered to be the key organ for birds in a long production cycle when birds are producing eggs for 90-100 weeks. The reason for this is the influence of the liver and its health and functioning on egg weight, laying rate, persistency in lay, egg shell quality, mortality, and feed conversion. The older birds become the more egg mass they have produced and the more challenging it is for the liver to keep healthy. The main challenge is the omnipresent risk of developing a fatty liver, as predisposing factors are frequently present in current commercial egg production circumstances. The source in which the energy is provided to the birds has an effect on the liver. From a metabolic point of view the formation of lipoprotein with lipids (fat) is efficient and easy for the liver, while energy from proteins and carbohydrates/starch is more taxing for the liver. Therefore a diet rich in fat helps to keep the liver healthy. Other very common predisposing factors seen in situations with production issues as a result of fatty livers are high temperatures, high energy intake, corn diets, fat birds, and cage housing systems. A fatty liver is in malfunction and birds will drop their production performance.

Furthermore, liver health is linked to egg shell quality through the metabolism of vitamin D. Egg shell quality deteriorates when the liver is less efficient in activating vitamin D3 which is necessary for calcium transportation to the egg gland. Nutritional factors that are able to stimulate the recovery of the liver and also able to prevent issues with fatty livers are diets high in fat instead of high in carbohydrates and the inclusion of choline, vitamin B12, folic acid, and vitamin E. Choline is highly effective and present in a wide variety of raw materials, like in soybean meal and rapeseed meal, although availability of choline in rapeseed meal is low. Wheat and corn also contain choline and higher concentrations are seen in wheat compared to corn. Although choline is present in quite a variety of raw materials, supplementary choline is always beneficial for the birds in production and therefore must be included in layer diets. Several factors determine the amount of added choline which is needed. The main factors are raw material selection, length of production period, and the desired safety margins as part of risk management. In situations of increased incidence start supplementing choline at 18 weeks of age. Advised added choline levels in the layer feed are 500 1000ppm, with 250ppm as an absolute minimum. Maintain hens’ capital throughout a longer production cycle by focusing on liver health and preventing the development of a fatty liver by providing energy from fat instead of energy from carbohydrates and by supplementation with sufficient amounts of choline.

Mineral supply

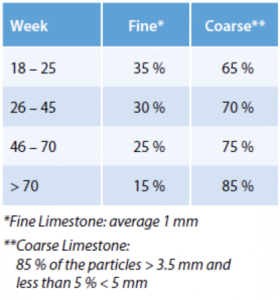

The rearing period is the most important factor for preparing the bird for the laying period. Skeletal development is finished for 95% around 11 weeks of age and when birds come into production calcium availability is again very important. An early flock must receive a pre-layer diet in order to meet calcium requirements, and a good and safe strategy is to start with the pre-layer diet at two weeks before the first egg is expected and continue up to 2% of lay at latest. At the start of lay calcium export to the egg is 1.9g. When birds receive an average developer diet, only 0.9g of calcium is offered via the feed. This situation will result in decalcification and transport from calcium from the bones towards the egg shell. In order to obtain a robust medullary bone, decalcification should be prevented. During egg production there is no big difference in mineral requirement between younger and old birds. However calcium source becomes even more important towards the end of the cycle. Calcium source should be coarse (2-4mm) and slowly soluble to extend the period of calcium absorption from the feed in the intestinal tract and thereby lower the level of decalcification from bones, which will also improve egg shell quality. Therefore, make sure calcium supply is at the correct level especially at the end of the rearing period (pre-layer diet) to minimize bone decalcification in order to achieve a robust medullary bone and provide coarse, slowly dissolving calcium during egg production.

Feeding technique

There is a strong relation between the applied feeding technique and mineral dynamics. Although calcium requirements will not be dramatically different for birds in longer production cycles, adaptations in management by adjusting the feeding technique have been shown to be beneficial. For maintaining good egg shell quality, the feeding technique seems to be more important than the actual nutrition in birds at the end of a longer production cycle. The objective for changing the feeding technique is to provide calcium from the feed at the moment of calcification of the egg shell. In this way the use of calcium from the feed is maximised, while minimising the mobilisation of calcium from the bones. The details of the recommended feeding technique are as follows: provide a morning feed (40% of the amount of feed), make sure feeders are empty at the middle of the day (for 1.0-1.5 hours in order to increase feed consumed at the end of the day), perform an afternoon feeding during 6 or 7 hours before light off moment (60% of the amount of feed), if possible include a midnight feed (1 -2 hours of light starting at 3.5 hours after light off moment). If possible in the daily operation, apply the concept of split feeding where two different diets are provided within a day. Split feeding enables the birds to meet their specific requirements, which results in a higher uptake of energy and amino acids in the morning, while in the afternoon calcium uptake is higher. This supply of nutrients fit the requirement for egg formation better and generally results in improved egg shell quality. In a long production cycle the moment of nutrients available is crucial for maintaining performance and therefore provide calcium at the moment of calcification.

Formulation tips

Starter

- Crumble feed presentation will improve growth and make it easier to reach the standard body weight.

- It could be interesting to invest in highlt digestible raw materials if they are available.

- Soya oil or coconut oil are better sources of energy than palm oil: at least during the first three weeks of age.

- A minimum of 0.30 % of salt will help to increase feed intake.

Grower

- Transition to mash feed if the starter was crumble feed.

- A minimum of 0.28 % of salt will help to have enough feed intake.

- A minimum of added fat will reduce the dustiness of the mash feed (1 – 2 % based on cost impact).

Developer

- Transition to mash feed if the starter was crumble feed.

- Crude fiber level needs to be as high as possible based on the available raw materials (> 3 %, up to 5.5 %). These values can be applied, or even exceeded, as long as they are of good quality.

- If the available raw materials don’t allow you to follow the recommendations below. Your Nutritionist should make a proportionally higher specification and the feed mill needs to make a higher particle size feed to compensate the lack of fibre.

- A minimum of added fat will reduce the dustiness of the mash feed (1 – 2 % based on cost impact).

Others

- Calcium particle size in pullet feed should be fine (average 1 mm).

- Enzymes: use and effect in the diet should be based on the available substrate in the diet.

- Antioxidants: protect against oxidation of the oils in the feed mill and the oxidation of fats and others in the diet.

- Organic minerals: provide additional benefits to the existing inorganics and may reduce the inclusion levels of the minerals.

Nutrient requirements

Fibre in the diet

- The feed intake development is one of the key factors for developing a pullet ready to lay. The feed intake capacity is related to the gut size, the addition of fibre in the diet expands the size of the gut and improves the feed intake capacity.

- The fibre concept is getting complex in poultry. There is new knowledge showing how different types have a different effect.

Fibre can be classified like:

- The total dietary fibre (TDF) is a sum of water soluble fibre (WSF), neutral detergent fibre (NDF), acid detergent fibre (ADF) crude fibre (CF) and acid detergent lignin (ADL).

- The addition of certain level of fibres since early ages will support the feed intake capacity (see table 10).

- There are several raw materials that can supply the necessary fibre in the diets to develop the feed intake capacity .

How to develop feed intake as the bird is growing and laying its first egg

Feed description & management

A transition feed that supports the final development of the pullet and the nutrient need for the start of lay.

- This feed is recommended to use until you reach 70 % of laying rate and have an increasing feed intake curve.

- This feed could be given since week 17 as replacement of the pre-lay.

Nutrient requirements

- The ideal protein profile is the same as in the layer rations.

- The vitamins and minerals are the same as in the layer rations.

- Crude fibre: keeping high levels as in the developer feed supports the feed intake development.

- Try to have a level minimum of 3.5 % or higher.

Formulation tips

- The addition of fats will give the formulation room for the requested calcium and fibre.

- The 60% of the calcium should be given in coarse calcium form.

- A minimum of salt, 0.28 %, will help in the feed intake stimulation.

How to feed hens for achieving as many as saleable eggs as possible during the laying period

FEED DESCRIPTION AND MANAGEMENT

Type of feed The feed should fulfill the maintenance, growth and production needs. The feed should be adjusted when:

- Egg mass changes: DO NOT change amino acids if the % lay drops unless the egg mass (% lay x size egg) is dropping too;

- Body weight changes: body weight affects energy needs, around +/-4 kcal every 50 grams of body weigh change;

- Feed intake changes: housing temperature will impact the feed intake. Hot temperature reduces the feed intake and vice versa.

Feed management on farm

Due to the variability of the raw materials the nutrient composition of the feed varies, to avoid this challenge we recommend to follow the Chart 1 decision tree:

- 40 % in the morning and 60 % in the afternoon (chart 2).

- Layer hens should clear all feed left in the feeder during the noon period.

- The time at which the feeder is empty depends on the lighting program.

Nutrients requirements

Energy

The energy recommendation of this guide doesn’t take into account the effect of the temperature in the needs of the layer hen. It needs additional adjustments by the nutritionist. Most of the energy intake will be used for maintenance. The body weight of the bird drives the energy requirement .

Amino acids

Most of the amino acid intake will be used for egg mass production. The egg mass, % lay x egg size, drives the amino acid needs .

Working with digestible AA is highly recommended when low digestible raw materials are used in the diet.

Formulation Tips

Crude Protein

Using the minimum amount of crude protein is recommended if there is limited information in nutrition about the raw materials.

Fat

Added fat will reduce the dustiness of mash feed (1 – 2 % based on cost impact).

Ca/P balance

- Levels of Ca and P must be adapted as the layer hen gets older.

- An excess or deficiency of P can cause eggshell issues in the short or long term.

- Coarse limestone is necessary for eggshell quality. It can be replaced in part by oyster shells.

Others

- Enzymes: use and effect in the diet should be based on the available raw materials in the diet.

- Antioxidants: protect against oxidation of the oils in the feed mill and the oxidation of fats and others in the diet.

- Organic minerals: provide additional benefits to the existing inorganics and may reduce the inclusion levels of the minerals.

Feed Structure

Mash feed is the most commonly used feed throughout the world. Layer hens tend to eat the larger particles avoiding the fine particle s which is where most of the key nutrients are. Therefore, it is vital for successful nutrition to have a uniform particle structure. It is even more important in non-beak treated birds. Crumble and pellet forms can be used as long as the structure holds in the feeding system of the birds and it doesn’t become a fine particle mash.

| LAYER BIRDS FEED FORMULATIONS | |||||||

| (SAMPLE) | |||||||

| Feed Raw Materials | Layer Chick Feed | Grower Feed 1 | Grower Feed 2 | Pre-layer Feed | Peak Feed | Layer Feed 1 | Layer Feed 2 |

| 0-7 week | 7-12 week | 12-17 week | 17.week-1% production | 1% production-40. week | 40-60 week | 60-80 week | |

| Raw Material | Quantity (kg) | Quantity (kg) | Quantity (kg) | Quantity (kg) | Quantity (kg) | Quantity (kg) | Quantity (kg) |

| Corn | 361 | 384 | 362 | 364 | 339 | 338 | 247 |

| Soybean Meal 46%CP | 234 | 100 | 52 | 95 | 176 | 141 | 125 |

| wheat | 250 | 250 | 300 | 300 | 300 | 300 | 400 |

| Bran | 0 | 89 | 108 | 34 | 0 | 0 | 0 |

| Sunflower Meal 36% CP | 100 | 120 | 120 | 120 | 53 | 83 | 88 |

| Oil | 18 | 20 | 20 | 20 | 20 | 20 | 20 |

| Limestone | 10 | 10 | 10 | 39 | 85 | 91 | 93 |

| Salt4 | 3 | 2 | 2 | 2 | 2 | 2 | 2 |

| LAYER PREMIX | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| TOTAL | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Nutrient Value | |||||||

| Crude Protein % | 21,000 | 17,000 | 15,500 | 16,394 | 17,000 | 16,500 | 16,422 |

| ME kcal/kg | 2920,000 | 2865,000 | 2865,000 | 2865,000 | 2800,000 | 2770,000 | 2750,000 |

| Crude Fiber % | 4,434 | 4,695 | 4,658 | 4,234 | 3,530 | 3,683 | 3,745 |

| Crude Ash % | 5,745 | 5,684 | 5,580 | 7,989 | 12,161 | 12,684 | 12,938 |

| Crude Oil % | 4,035 | 4,541 | 4,584 | 4,338 | 4,154 | 4,130 | 3,961 |

| Calcium % | 1,000 | 1,000 | 1,000 | 2,000 | 3,700 | 3,900 | 4,000 |

| Phosphorus % | 0,803 | 0,855 | 0,863 | 0,729 | 0,651 | 0,667 | 0,681 |

| Av. Phosphorus % | 0,481 | 0,487 | 0,487 | 0,396 | 0,382 | 0,382 | 0,387 |

| Sodium % | 0,180 | 0,160 | 0,150 | 0,160 | 0,160 | 0,160 | 0,160 |

| Potassium % | 0,866 | 0,659 | 0,580 | 0,644 | 0,691 | 0,665 | 0,648 |

| Lysine % | 1,095 | 0,802 | 0,690 | 0,750 | 0,865 | 0,805 | 0,780 |

| D-Lysine % | 0,982 | 0,702 | 0,597 | 0,662 | 0,774 | 0,719 | 0,691 |

| Methionine % | 0,443 | 0,397 | 0,377 | 0,399 | 0,386 | 0,387 | 0,384 |

| D-Methionine % | 0,413 | 0,366 | 0,345 | 0,361 | 0,351 | 0,352 | 0,348 |

| Tryptophan % | 0,251 | 0,202 | 0,184 | 0,191 | 0,200 | 0,193 | 0,195 |

| D-Tryptophan % | 0,212 | 0,166 | 0,149 | 0,156 | 0,168 | 0,161 | 0,162 |

| Threonine % | 0,797 | 0,634 | 0,570 | 0,599 | 0,630 | 0,608 | 0,595 |

| D-Threonine % | 0,701 | 0,547 | 0,488 | 0,520 | 0,552 | 0,532 | 0,520 |

| Arginine % | 1,398 | 1,111 | 0,992 | 1,063 | 1,084 | 1,060 | 1,047 |

| D-Arginine % | 1,292 | 1,015 | 0,901 | 0,979 | 0,998 | 0,978 | 0,963 |

| Meth-Cyst % | 0,815 | 0,724 | 0,688 | 0,718 | 0,699 | 0,697 | 0,699 |

| D-Meth+Cyst % | 0,730 | 0,642 | 0,608 | 0,633 | 0,619 | 0,617 | 0,620 |

| Linoleic Acid % | 1,917 | 2,159 | 2,177 | 2,080 | 1,985 | 1,982 | 1,888 |

LAYER PREMIX SHOULD CONTEN

| VITAMINS |

|

| MINERALS |

|

| AMINO ACIDS |

|

| ENZYMES |

|

| EGG YOLK COLORANT |

|

| ORGANIC ACIDS |

|

| OTHER FEED ADDITIVES |

|

Principles of Commercial Poultry Farming

Poultry Nutrition Management Guide

FORMULATION OF RATION FOR POULTRY

FEEDING MANAGEMENT OF POULTRY (BROILER & LAYERS) PPT

Chicken-Layer-Management-Manual

CAGE HOUSING LAYER MANAGEMENT GUIDE

Compiled & Shared by- Team, LITD (Livestock Institute of Training & Development)

Image-Courtesy-Google

Reference-On Request.